Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu troughing roller

The Role of Troughing Rollers in Bulk Material Handling

In the dynamic world of bulk material handling, the design and functionality of conveyor systems play a crucial role in ensuring efficiency and effectiveness. Among the myriad components that facilitate the smooth operation of these systems, troughing rollers stand out due to their importance in the transportation and management of bulk materials.

What Are Troughing Rollers?

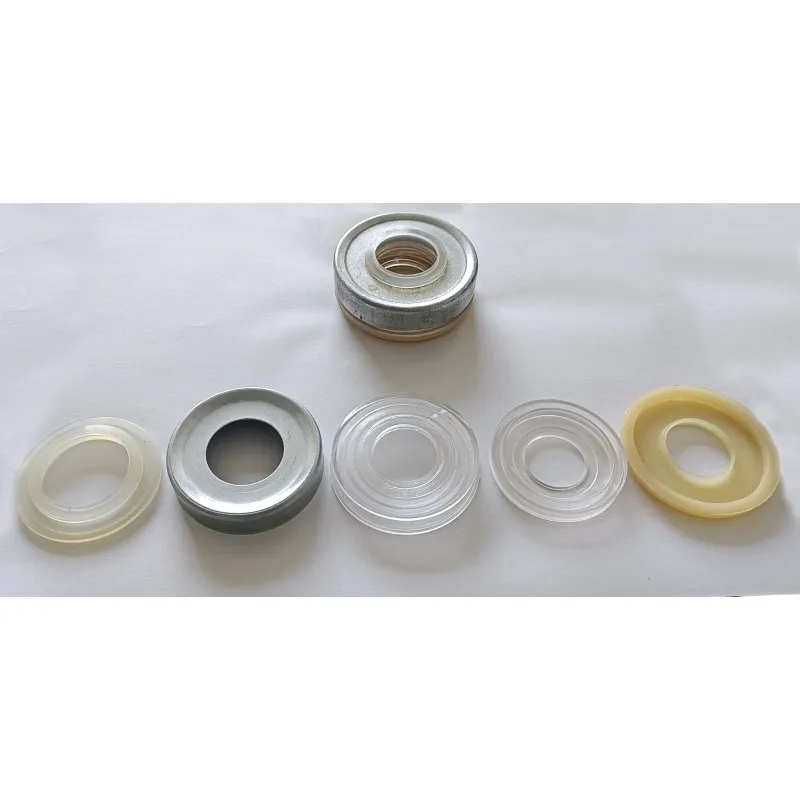

Troughing rollers are specialized components used in belt conveyors that help to support and guide the conveyor belt as it transports materials. Unlike flat rollers, troughing rollers have a concave design, which allows them to create a trough shape in the conveyor belt. This design is particularly beneficial for handling bulk materials since it aids in confining the materials within the center of the belt, reducing spillage and increasing load stability. Typically, troughing rollers are arranged in sets, often with an angle of 20 to 35 degrees, depending on the application and the type of material being transported.

Importance in Bulk Material Transport

One of the primary advantages of using troughing rollers is their ability to enhance load-carrying capacity. The trough shape allows for higher load volumes to be carried without the risk of spillage. This is especially important in industries such as mining, agriculture, and construction, where bulk materials like coal, gravel, and grain are frequently transported. Less spillage means less waste and a more efficient operation overall.

Additionally, troughing rollers help to maintain the alignment of the belt

. When bulk materials are loaded onto a conveyor belt, they can create uneven weight distribution. Troughing rollers mitigate this issue by helping to center the load, which reduces the likelihood of the belt drifting off its intended path. This alignment is crucial for the longevity of the conveyor system, as misalignment can lead to increased wear on the belt and rollers, resulting in costly maintenance and downtime.Design and Material Considerations

troughing roller

Troughing rollers are typically made from durable materials such as steel or polymer, chosen for their strength and resistance to wear. The choice of material can significantly influence the operational lifespan of the rollers and the conveyor system as a whole. Moreover, the design of troughing rollers may vary based on the specific requirements of the application. For instance, self-cleaning troughing rollers are available, which help prevent the build-up of material on the roller surface, enhancing performance and reducing maintenance needs.

Furthermore, the angle and spacing between the rollers are critical factors in their design. The angle of the troughing roller affects the volume of material that can be carried, while the spacing determines how well the belt is supported. Engineers must carefully calculate these parameters to optimize the conveyor system for its intended use.

Challenges and Solutions

Despite their advantages, troughing rollers are not without challenges. Over time, they can suffer from wear and tear due to the abrasive nature of the materials they convey, leading to potential failures. Regular maintenance is crucial to identify and address issues such as misalignment, wear, and damage. Implementing advanced monitoring systems can also help in predicting maintenance needs before they become critical, thereby minimizing downtime.

Innovative solutions such as enhanced roller designs with better bearing seals and materials that resist wear are gaining traction within the industry. These advancements aim to improve the longevity and reliability of troughing rollers, aligning with the industry’s growing emphasis on efficiency and sustainability.

Conclusion

In conclusion, troughing rollers are essential components in bulk material handling systems, offering significant benefits in load stability, alignment, and operational efficiency. Their design and functionality help maintain the integrity of the conveyor belt and reduce material spillage, which is vital for maintaining productivity and minimizing waste. As industries continue to evolve and the demand for effective bulk material handling systems grows, the importance of troughing rollers and their innovative developments will likely remain at the forefront of engineering solutions. Investing in high-quality troughing rollers is not just a matter of efficiency; it is a commitment to the sustainable and effective management of resources in the ever-demanding landscape of bulk material transport.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025