Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Top Quality Idler Roller Suppliers for Your Industrial Needs and Applications

The Role of Idler Roller Manufacturers in Conveyor Systems

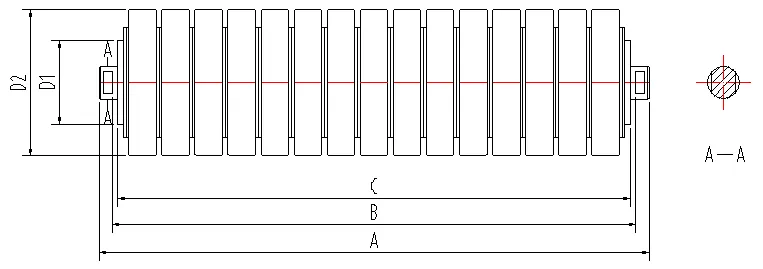

In the world of industrial and manufacturing processes, the efficiency of material handling systems is crucial. Central to these systems are conveyor belts, which are essential for transporting goods across various stages of production and logistics. One pivotal component that enhances the functionality of conveyor systems is the idler roller. Idler roller manufacturers play a vital role in producing high-quality idler rollers that ensure smooth operation and longevity of conveyor systems.

Understanding Idler Rollers

Idler rollers are cylindrical devices that support the conveyor belt’s weight. They are typically positioned at intervals along the pathway of the conveyor belt to maintain tension and improve belt alignment. Idler rollers do not drive the belt but instead revolve as the belt travels over them. Their purpose is to reduce friction and wear on the belt, thus prolonging the operational life of the conveyor system and improving overall efficiency.

The Importance of Quality in Manufacturing

The effectiveness of an idler roller is highly dependent on the quality of its construction. Idler roller manufacturers utilize various materials and technologies to produce rollers that can withstand different environmental conditions, loads, and speeds. High-quality idler rollers will be resistant to wear and tear, capable of enduring heavy loads, and efficient in reducing friction. Manufacturers often use materials such as carbon steel, stainless steel, and various compounds designed for durability and performance.

Customization to Meet Specific Needs

One of the significant advantages of working with specialized idler roller manufacturers is the ability to customize products to meet specific operational requirements. Industries such as mining, agriculture, and manufacturing have distinct needs based on the types of materials being transported, the speed of transport, and the environmental conditions in which these systems operate. Custom idler rollers can be designed with specific features, such as increased diameter, specialized bearings, or particular seal designs to enhance resistance to dust and moisture.

idler roller manufacturer

Technological Advances in Idler Roller Manufacturing

In recent years, advancements in technology have transformed how idler rollers are produced. Using CAD (Computer-Aided Design) software, manufacturers can create precise designs that optimize performance. Advanced materials and coating technologies now allow for the development of rollers that are lighter yet stronger, reducing the overall weight of the conveyor system while maintaining its strength. Additionally, innovations in bearing technology have resulted in smoother operation, reduced friction, and lower maintenance requirements.

Environmental Considerations

As industries become more environmentally conscious, idler roller manufacturers are also paying attention to the sustainability of their products. This involves sourcing materials responsibly, reducing waste in the manufacturing process, and creating products that are recyclable. Some manufacturers are exploring the use of biodegradable materials or offering refurbishment services for worn-out rollers, thereby minimizing the environmental footprint of their operations.

The Future of Idler Roller Manufacturing

Looking ahead, the demand for high-performance idler rollers is expected to grow with the rise of automation and digital technologies in manufacturing. As industries continue to implement smart technologies and IoT (Internet of Things) systems, the need for reliable material handling equipment will become even more critical. Idler roller manufacturers will need to keep pace with these trends by integrating smart features into their products, such as sensors for monitoring performance and predictive maintenance tools.

In conclusion, idler roller manufacturers are essential contributors to the efficiency and effectiveness of conveyor systems. By focusing on quality, customization, technological integration, and sustainability, they ensure that industries can operate smoothly, safely, and with minimal downtime. The future of idler roller manufacturing is bright, promising innovation and enhanced capabilities that will further elevate industrial operations across the globe.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025