Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Top Conveyor Equipment Manufacturers You Should Know

In the world of industrial material handling, the efficiency of your systems can make or break productivity. One key factor in achieving smooth operations is choosing the right conveyor components, from conveyor idler manufacturers to belt conveyor drum pulley manufacturers and drive pulley manufacturers. These manufacturers play a crucial role in optimizing the movement of goods across various industries, ensuring maximum uptime and reliability. Here’s a breakdown of the top manufacturers shaping the future of conveyor systems.

Top Conveyor Idler Manufacturers for Maximum Efficiency

When it comes to ensuring smooth and efficient conveyor operation, conveyor idler manufacturers are at the forefront. Idlers are crucial components that reduce friction and support the conveyor belt, allowing for seamless material transportation. Leading manufacturers in the industry focus on producing high-quality idlers designed to withstand the harshest industrial conditions. Their products are engineered for durability and reliability, which ultimately helps businesses reduce downtime, maintenance costs, and improve the overall performance of their conveyor systems.

By selecting the right conveyor idler manufacturers, companies can enhance the efficiency of their material handling systems while ensuring long-term sustainability. The latest advancements in idler technology also contribute to energy savings, making them a critical part of cost-effective, environmentally friendly conveyor solutions.

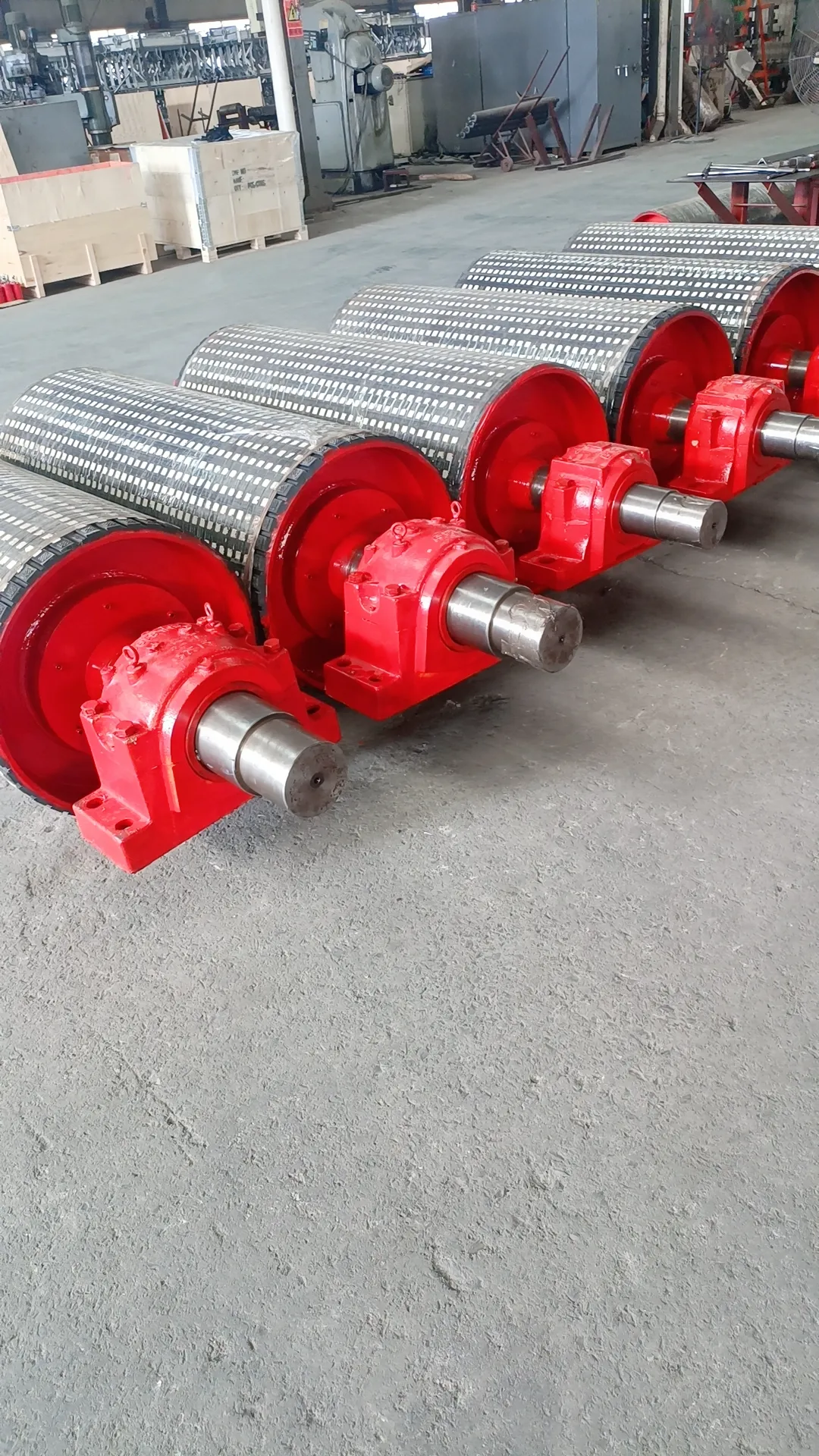

Reliable Belt Conveyor Drum Pulley Manufacturers for Better Power Transmission

For conveyors to operate smoothly and efficiently, belt conveyor drum pulley manufacturers play an essential role in power transmission. The drum pulley is the primary component that drives the belt, enabling it to move materials over long distances. These pulleys must be durable, precision-engineered, and capable of handling significant amounts of torque. The best belt conveyor drum pulley manufacturers use advanced materials and engineering techniques to ensure that their pulleys are both strong and long-lasting, minimizing the need for replacements or repairs.

From heavy-duty industrial applications to lighter systems, manufacturers of belt conveyor drum pulleys offer customizable solutions to meet specific operational needs. By selecting trusted and experienced suppliers, companies can ensure optimal belt tension, improved efficiency, and reduced operational disruptions. Innovations in drum pulley design also focus on minimizing energy consumption, which helps businesses lower operational costs in the long run.

Drive Pulley Manufacturers: Ensuring Optimal Belt Movement

The drive pulley manufacturers are key players in ensuring that a conveyor system operates with precision and efficiency. Drive pulleys are responsible for powering the conveyor belt, transmitting force from the motor to the belt itself. These pulleys must be engineered to handle substantial loads while maintaining perfect synchronization with the rest of the system. High-quality drive pulleys help ensure that the conveyor belt moves consistently without slipping or experiencing unnecessary wear.

Leading drive pulley manufacturers invest in advanced materials, such as high-strength steel, to produce pulleys that withstand heavy loads, high-speed operations, and the toughest conditions. This makes drive pulleys not only vital for high-performance conveyors but also for improving the lifespan and reliability of the entire system. When choosing a manufacturer, companies should look for those with a proven track record of supplying high-quality drive pulleys that optimize power transfer and minimize maintenance needs.

Choosing the Right Conveyor Component Manufacturers for Sustainable Operations

Selecting the right conveyor component manufacturers is essential for achieving long-term operational success. Whether you’re sourcing conveyor idlers, belt conveyor drum pulleys, or drive pulleys, it’s crucial to partner with manufacturers that prioritize quality, innovation, and sustainability. The modern industrial landscape demands solutions that not only perform well but also align with environmental standards and energy efficiency goals.

By working with trusted conveyor idler manufacturers, belt conveyor drum pulley manufacturers, and drive pulley manufacturers, businesses can invest in components that reduce their carbon footprint, lower operational costs, and enhance overall system performance. Many top manufacturers are embracing eco-friendly practices, including the use of recycled materials and energy-efficient production processes. For companies looking to future-proof their operations, these sustainability efforts can make a significant difference.

The Future of Conveyor Equipment: Technological Advancements and Trends

The future of conveyor systems lies in the continuous evolution of technology. Leading conveyor idler manufacturers, belt conveyor drum pulley manufacturers, and drive pulley manufacturers are constantly innovating, integrating new technologies to improve performance, reduce wear, and enhance energy efficiency. Automation, IoT (Internet of Things) integration, and smart sensors are transforming how conveyors operate, allowing for predictive maintenance, remote monitoring, and system optimization.

As demand for more sustainable and efficient conveyor systems grows, manufacturers are focusing on developing products that support automation and reduce environmental impact. The latest advancements in materials science, such as the use of lighter but stronger materials, are contributing to more energy-efficient and durable conveyor components. With these ongoing innovations, companies can expect even greater reliability and efficiency from their conveyor systems in the years ahead.

By choosing the right conveyor idler manufacturers, belt conveyor drum pulley manufacturers, and drive pulley manufacturers, companies can stay ahead of the curve and ensure their material handling systems are ready for the challenges of the future.

In conclusion, the importance of selecting the right manufacturers for your conveyor equipment cannot be overstated. Whether you are looking for conveyor idler manufacturers, belt conveyor drum pulley manufacturers, or drive pulley manufacturers, quality and innovation should be your top priorities. With the right partners, businesses can improve operational efficiency, reduce downtime, and contribute to a more sustainable future in material handling.

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025