Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu The Importance of Rubber Lagging Pulley in Conveyor Systems

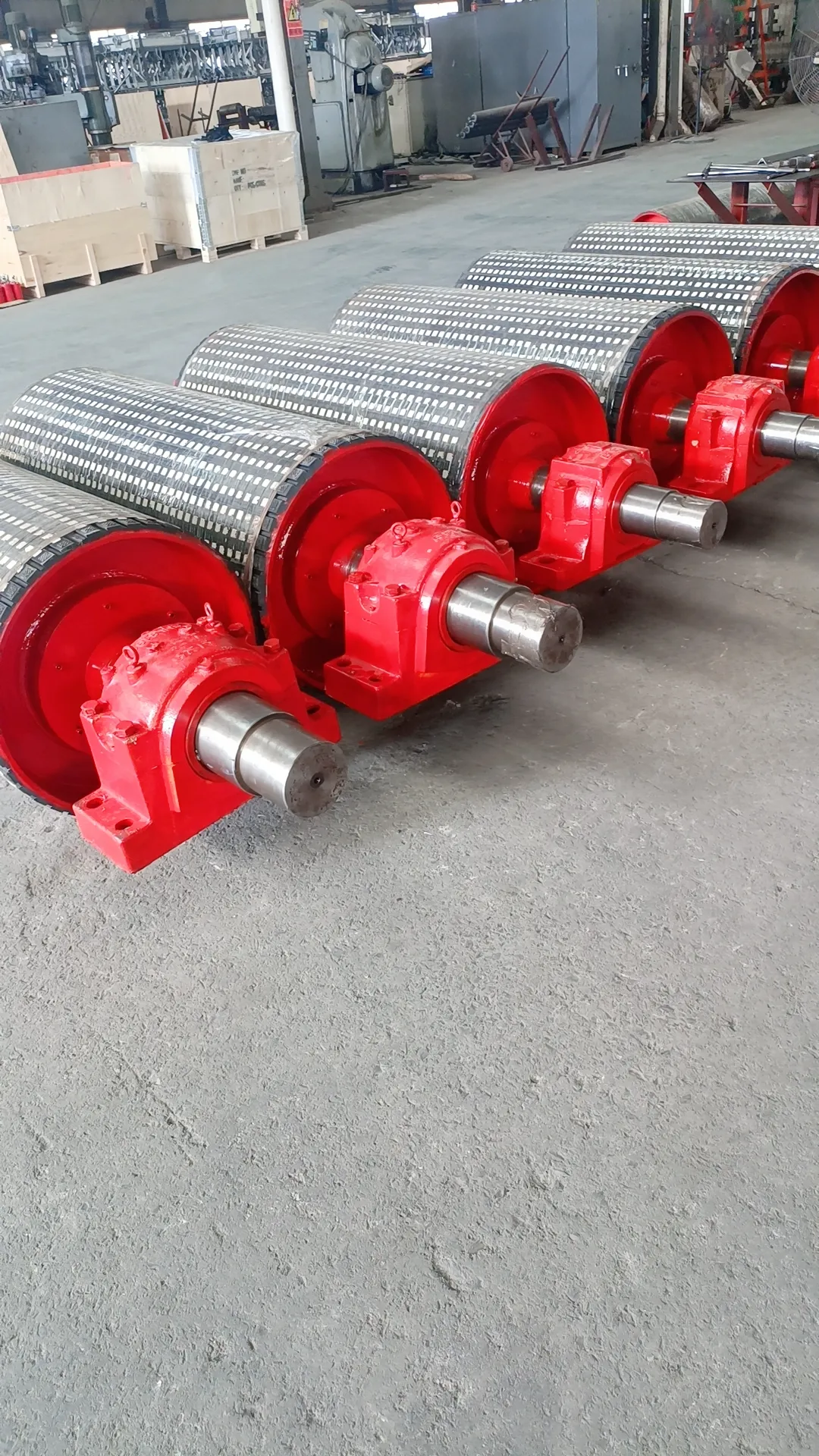

In modern industrial operations, conveyor systems play a crucial role in efficiently moving materials from one location to another. One of the key components of a conveyor system is the pulley, and ensuring it functions optimally is vital for the system’s overall performance. One of the most effective ways to enhance the performance of a pulley is through rubber lagging.

What is Rubber Lagging Pulley?

A rubber lagging pulley refers to a pulley that is coated with a layer of rubber, designed to improve its grip and efficiency in conveyor systems. The rubber coating helps to increase friction between the pulley and the conveyor belt, minimizing slippage and maximizing the transmission of power. This is especially critical in systems where high torque or heavy loads are involved.

Pulley lagging is the process of applying a rubber covering to the pulley. This lagging not only boosts the pulley’s traction but also provides protection against wear and tear. As pulleys operate under high stress and friction, the rubber layer acts as a shield, reducing the chances of corrosion, rust, and damage to the metal surface. In addition, rubber lagging improves belt tracking and reduces belt misalignment, contributing to smoother operations and longer system lifespans.

Advantages of Rubber Lagging in Conveyor Systems

Rubber lagging offers several significant benefits. First, it enhances pulley lagging by increasing the coefficient of friction, leading to more effective power transmission. This means conveyor belts run more smoothly and efficiently, which can reduce maintenance costs over time. Rubber lagging also offers excellent durability and resilience to varying environmental conditions, such as temperature fluctuations, water, or harsh chemicals.

Another advantage is that rubber lagging absorbs vibrations, reducing noise levels during operation. This not only makes the system quieter but also minimizes stress on the pulley and belt, extending their life expectancy. Furthermore, the wear-resistant properties of rubber lagging ensure the pulley remains in good condition, even under heavy-duty usage.

Conclusion: Invest in Rubber Lagging for Maximum Efficiency

Incorporating rubber lagging into your conveyor system’s pulleys is a simple yet effective way to boost its performance and longevity. Whether you are looking to reduce maintenance costs, enhance grip, or improve belt tracking, rubber lagging provides a reliable solution. Upgrade your pulley system today with quality rubber lagging and experience smoother, more efficient operations.

Take action now and improve the efficiency of your conveyor systems by investing in high-quality rubber lagging!

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025