Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu The Advantages of Ceramic Lagging Conveyor Pulley for Industrial Efficiency

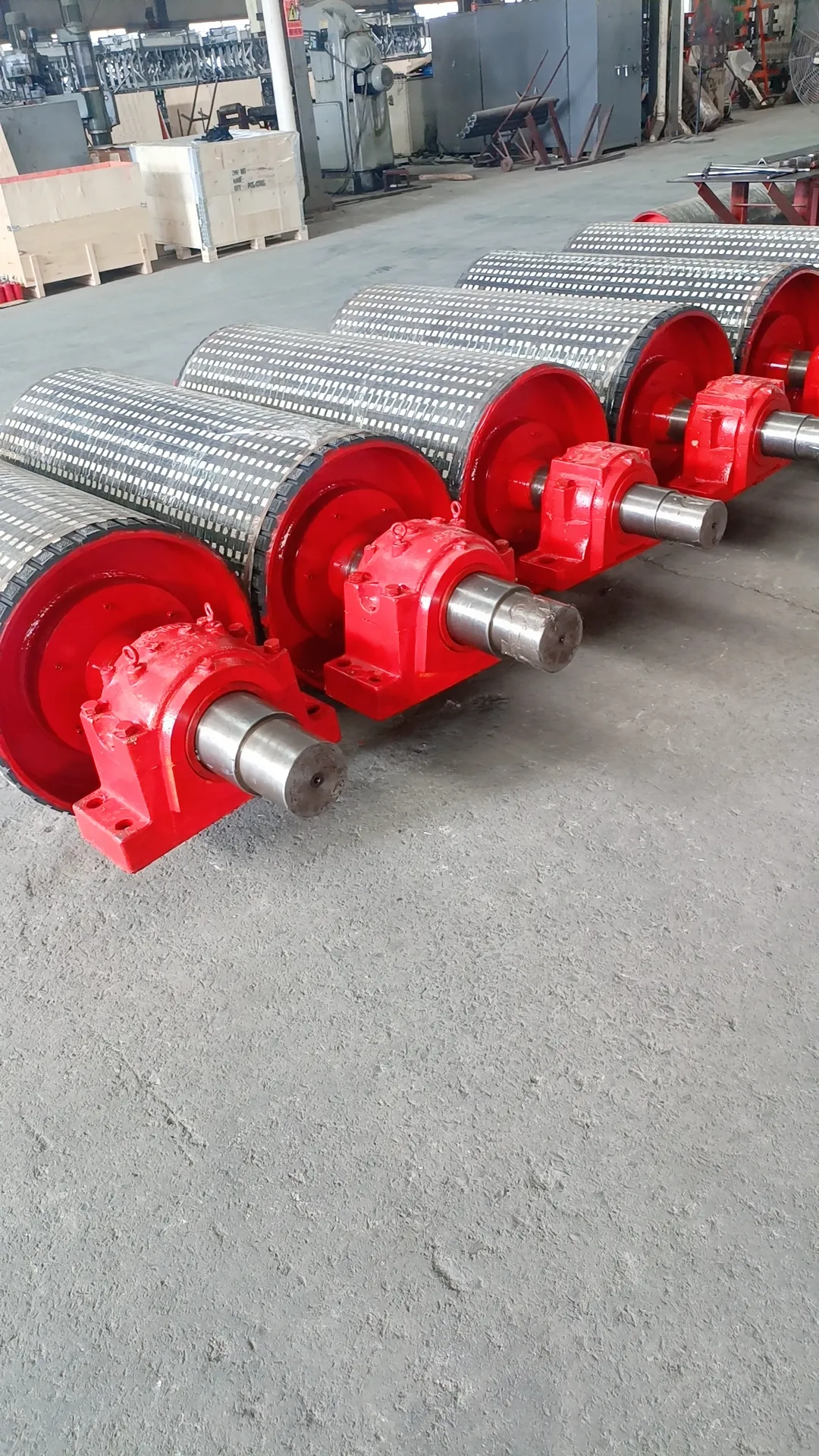

Conveyor systems are integral to various industries, facilitating the efficient movement of goods over long distances. One of the critical components of these systems is the conveyor pulley, which plays a significant role in the functionality and longevity of the entire operation. In recent years, the introduction of ceramic lagging conveyor pulley has revolutionized the way industries approach conveyor maintenance and performance. This article explores the advantages of ceramic lagging pulley and how they can enhance the efficiency of your conveyor system.

Improved Traction and Reduced Slippage

A major issue faced in conveyor systems is the slippage of the conveyor belt, particularly when operating under heavy loads or in wet, muddy conditions. Ceramic lagging conveyor pulley are designed to address this problem by providing superior traction between the belt and pulley surface. The ceramic-coated surface of the pulley creates a rougher texture that ensures better grip, reducing the likelihood of slippage. This enhancement leads to smoother, more consistent operations, ensuring that the conveyor belt remains aligned and reduces the wear and tear on the belt.

Moreover, ceramic lagging pulley are especially beneficial in high-moisture environments, such as in mining, quarrying, and other heavy-duty industries. The ceramic material’s resistance to water and other harsh elements ensures that the pulley maintains its performance, even in challenging conditions.

Increased Durability and Reduced Maintenance Costs

Another significant advantage of ceramic lagging pulley is their durability. Ceramic is known for its hardness and resistance to abrasion, making it an excellent material for prolonging the lifespan of conveyor pulleys. With a ceramic lagging pulley, the surface of the pulley is less likely to wear down over time, which means fewer replacements and lower maintenance costs. This increased durability also leads to fewer unscheduled downtimes, enhancing overall productivity.

Additionally, ceramic pulley provide greater resistance to corrosion, especially in environments where chemical exposure is prevalent. This further reduces the need for regular maintenance, saving companies both time and money in the long run.

Upgrade Your Conveyor System Today

If you're looking to enhance the efficiency, longevity, and performance of your conveyor system, investing in ceramic lagging conveyor pulley is a smart choice. By improving traction and reducing maintenance costs, ceramic pulley can significantly contribute to the smooth operation of your business. Contact a trusted supplier today to learn more about ceramic lagging pulley and how they can benefit your operations.

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025