Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 25, 2025 01:07

Back to list

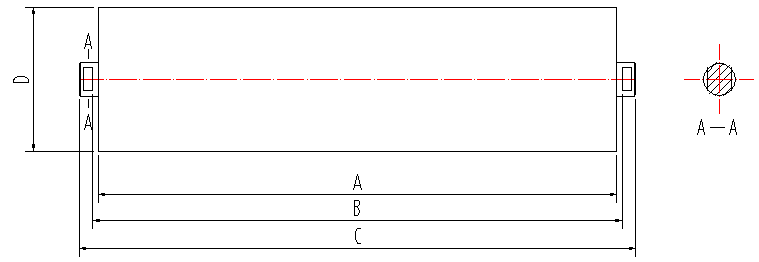

tapered conveyor rollers

Tapered conveyor rollers have become an essential component in modern manufacturing and distribution processes. With increasing demands for more efficient material handling solutions, these rollers play a crucial role in improving operational productivity and flexibility. Unlike traditional conveyor rollers, tapered ones are designed with a conically shaped geometry that allows them to handle materials on curved or turning conveyor paths smoothly.

Trustworthiness is paramount when selecting and deploying tapered conveyor rollers. Reputable manufacturers ensure their products meet international safety and quality standards, providing peace of mind to businesses looking to upgrade or expand their conveyor systems. Rigorous testing and certification processes ensure these rollers can withstand the demanding environments of modern industrial operations, from heavy-load requirements in manufacturing plants to temperature-sensitive conditions in food processing facilities. Experience shows that businesses leveraging the benefits of tapered conveyor rollers can achieve significant competitive advantages. Faster transfer rates, reduced product damage, and enhanced alignment and tracking capabilities lead to improved order accuracy and shorter delivery times. These factors contribute positively to customer satisfaction, an increasingly vital metric in today's service-focused marketplace. Moreover, adapting to the integration of technologies such as the Internet of Things (IoT) and Industry 4.0, modern tapered conveyor rollers are designed with smart capabilities. These enhancements allow for real-time tracking and data analysis, providing operators with valuable insights into operational efficiencies and potential areas of improvement. The ability to predict system failures and proactively address maintenance needs ensures continuous operation and optimal equipment utilization. In conclusion, tapered conveyor rollers are vital components of contemporary material handling systems, praised for their ability to enhance efficiency and reliability while reducing costs. Their design accommodates complex conveyor paths, ensuring the smooth transition of goods through various stages of the manufacturing and distribution process. By investing in high-quality tapered conveyor rollers, businesses not only streamline operations but also position themselves for future growth through scalabilty and technological advancement.

Trustworthiness is paramount when selecting and deploying tapered conveyor rollers. Reputable manufacturers ensure their products meet international safety and quality standards, providing peace of mind to businesses looking to upgrade or expand their conveyor systems. Rigorous testing and certification processes ensure these rollers can withstand the demanding environments of modern industrial operations, from heavy-load requirements in manufacturing plants to temperature-sensitive conditions in food processing facilities. Experience shows that businesses leveraging the benefits of tapered conveyor rollers can achieve significant competitive advantages. Faster transfer rates, reduced product damage, and enhanced alignment and tracking capabilities lead to improved order accuracy and shorter delivery times. These factors contribute positively to customer satisfaction, an increasingly vital metric in today's service-focused marketplace. Moreover, adapting to the integration of technologies such as the Internet of Things (IoT) and Industry 4.0, modern tapered conveyor rollers are designed with smart capabilities. These enhancements allow for real-time tracking and data analysis, providing operators with valuable insights into operational efficiencies and potential areas of improvement. The ability to predict system failures and proactively address maintenance needs ensures continuous operation and optimal equipment utilization. In conclusion, tapered conveyor rollers are vital components of contemporary material handling systems, praised for their ability to enhance efficiency and reliability while reducing costs. Their design accommodates complex conveyor paths, ensuring the smooth transition of goods through various stages of the manufacturing and distribution process. By investing in high-quality tapered conveyor rollers, businesses not only streamline operations but also position themselves for future growth through scalabilty and technological advancement.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS