Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

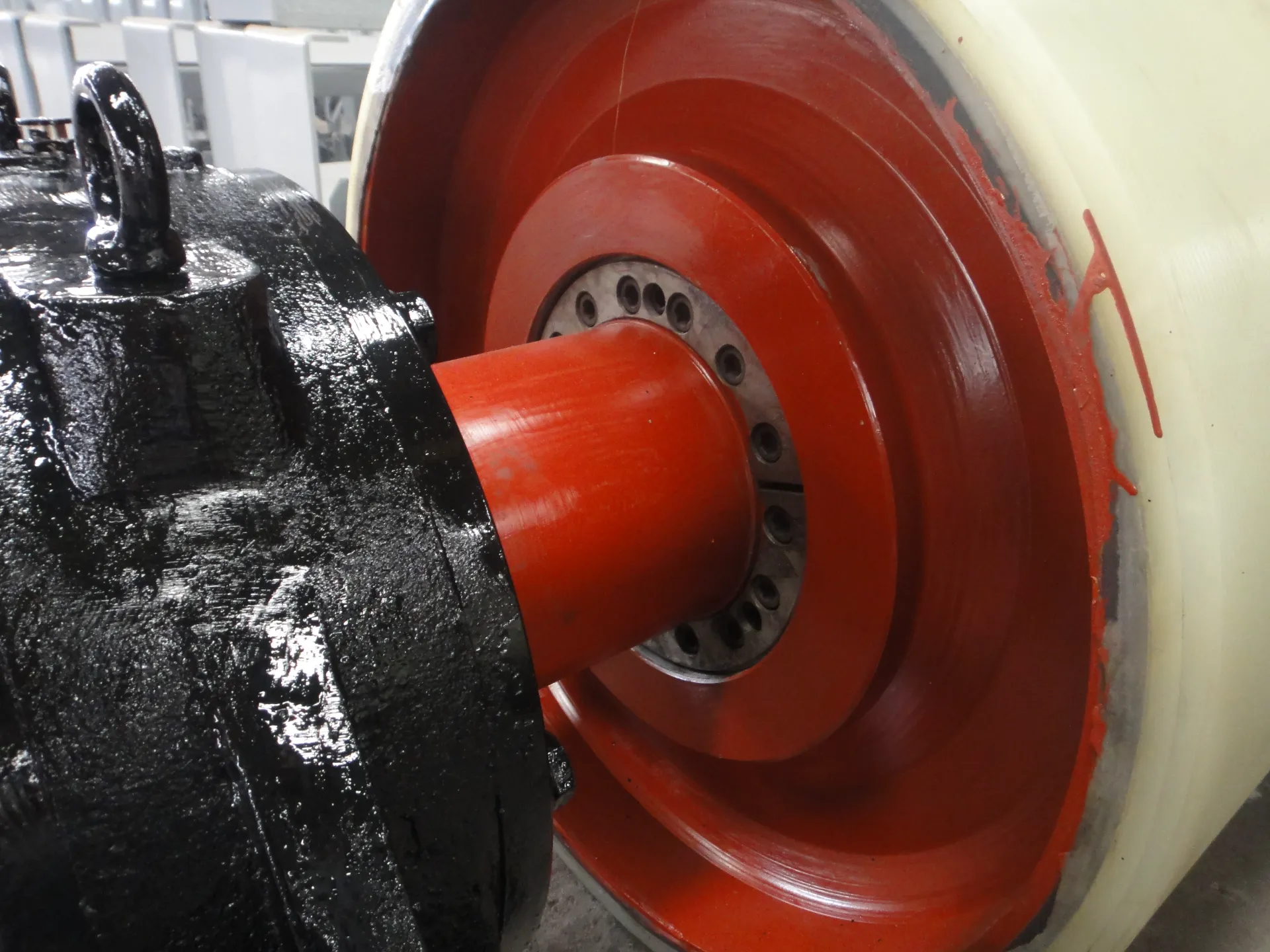

Zulu Tapered Conveyor Rollers for Enhanced Material Handling Efficiency and Performance

Understanding Tapered Conveyor Rollers Enhancing Material Handling Efficiency

In today's fast-paced industrial environment, efficient material handling is crucial for maximizing productivity. One essential component that has significantly improved these operations is the tapered conveyor roller. These rollers, designed with a slight incline, facilitate the movement of goods along conveyor systems while optimizing space and enhancing the overall efficiency of the handling process.

What Are Tapered Conveyor Rollers?

Tapered conveyor rollers are cylindrical components that are wider at one end than the other, creating a tapering effect. This design allows for the rolling surface to create a natural incline, which is particularly useful in applications where products need to be guided or directed. These rollers are commonly made from durable materials such as steel, plastic, or rubber to ensure longevity and performance in various working environments.

Advantages of Tapered Conveyor Rollers

1. Improved Material Flow The tapered design of these rollers enhances the natural flow of materials on the conveyor. Items tend to gravitate towards the center of the roller, minimizing the risk of misalignment or spilling. This is particularly advantageous in the transport of small or irregularly shaped items that could easily fall off a flat surface.

2. Space Efficiency Tapered rollers allow for more compact designs of conveyor systems. By enabling products to be moved more closely together, businesses can maximize their available space and reduce the footprint of their operations. This is a significant advantage in environments where space is at a premium.

3. Versatility in Applications Tapered conveyor rollers can be utilized in a variety of industries, from packaging and manufacturing to warehousing and distribution. They are effective in handling diverse materials, including boxes, crates, and even bulk items. Their versatility makes them a staple component in many conveyor systems.

4. Reduced Wear and Tear The design of tapered rollers often leads to reduced friction and wear on the transported materials. This helps in prolonging the lifespan of both the rollers and the goods being transported, translating to lower maintenance costs and improved productivity in the long run.

tapered conveyor rollers

5. Easy Installation and Maintenance Most tapered conveyor rollers are designed for quick installation and ease of maintenance. Their straightforward configuration allows for seamless integration into existing systems, making it simpler for businesses to upgrade their operations without extensive downtime.

Selecting the Right Tapered Conveyor Roller

When choosing tapered conveyor rollers, it’s essential to consider several factors to ensure they meet the specific needs of your operation

- Load Capacity Understand the weight and size of the materials that will be transported. Tapered rollers come in various sizes and weight capacities, so it's crucial to select those that can handle your operational requirements without compromising performance.

- Material Composition The material of the roller affects durability, grip, and suitability for different environments. For instance, rubber rollers provide better grip and shock absorption, while steel rollers are favored for their strength and longevity under heavy loads.

- Roller Diameter and Taper Angle The diameter and taper angle influence how items travel on the conveyor. Selecting the appropriate dimensions based on the types of products being handled will ensure smooth and efficient transport.

- Environmental Factors Consider the environment in which the conveyor will operate. Factors such as temperature, moisture, and exposure to chemicals can affect roller performance and longevity. Ensure that the selected materials are suitable for your specific working conditions.

Conclusion

Tapered conveyor rollers represent a vital advancement in material handling technology, offering a perfect blend of efficiency, versatility, and cost-effectiveness. Their unique design aids in the smooth transport of goods and maximizes operational spaces, making them invaluable in various industrial applications. As industries continue to evolve and demands for greater efficiency grow, the importance of tapered conveyor rollers in ensuring streamlined operations cannot be overstated. By selecting the right roller for your applications, you can enhance your material handling processes and drive your business towards greater success.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025