Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jun . 28, 2024 02:00

Back to list

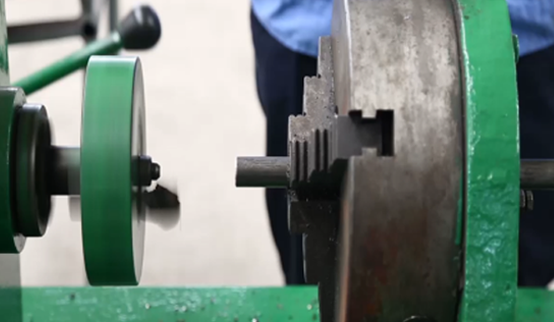

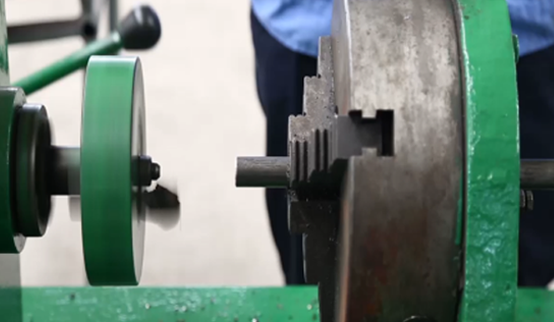

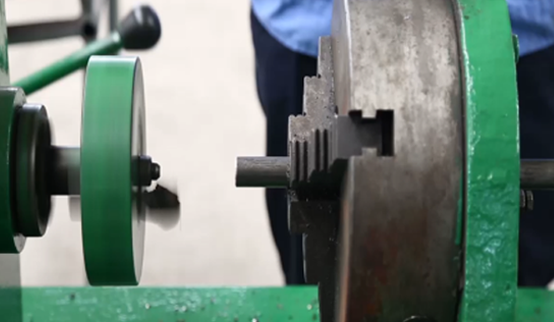

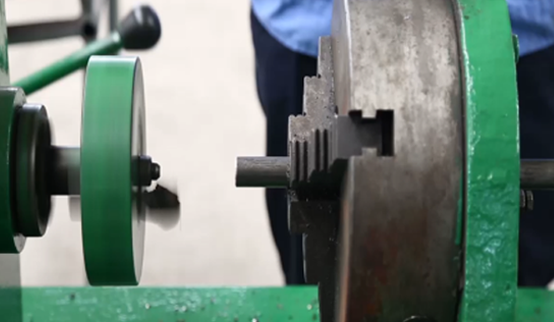

Tapered Shaft Belt Pulley Understanding the Benefits and Applications

The Comparative Analysis Tapered Shaft vs. V-Belt Pulley Systems

In the realm of mechanical engineering, efficient power transmission is a critical aspect that impacts overall system performance. Two popular mechanisms for this purpose are the tapered shaft and V-belt pulley systems. Both have their unique advantages and applications, making them indispensable in various industries.

A tapered shaft, also known as a stepped shaft, is characterized by its gradual change in diameter along its length. This design allows for a secure and precise fit between the shaft and the component it connects, reducing slippage and enhancing torque transmission. The tapering ensures a tight, self-aligning connection, minimizing the need for additional bearings or bushings. It is widely used in applications where high torque and minimal play are essential, such as in automotive engines and heavy machinery.

On the other hand, V-belt pulley systems rely on the friction between a V-shaped belt and a matching pulley to transmit power. These systems are popular due to their versatility and ability to handle large amounts of power over long distances with minimal noise and wear. They are effective in applications where a constant speed is required, such as in HVAC systems, agricultural equipment, and conveyor belts They are effective in applications where a constant speed is required, such as in HVAC systems, agricultural equipment, and conveyor belts They are effective in applications where a constant speed is required, such as in HVAC systems, agricultural equipment, and conveyor belts They are effective in applications where a constant speed is required, such as in HVAC systems, agricultural equipment, and conveyor belts

They are effective in applications where a constant speed is required, such as in HVAC systems, agricultural equipment, and conveyor belts They are effective in applications where a constant speed is required, such as in HVAC systems, agricultural equipment, and conveyor belts tapered shaft v belt pulley. V-belts also offer the advantage of being easily replaceable and adjustable, allowing for maintenance without disrupting the entire system.

While a tapered shaft offers superior strength and precision, it may require more complex manufacturing processes and can be less adaptable to changes in alignment. Conversely, V-belt pulley systems, though slightly less efficient in power transfer, provide flexibility and ease of maintenance. Their ability to accommodate misalignment makes them suitable for applications where perfect shaft alignment is difficult to achieve.

In conclusion, the choice between a tapered shaft and a V-belt pulley system largely depends on the specific requirements of the application. Tapered shafts excel in high-torque, precision-driven scenarios, while V-belt pulleys are ideal for systems needing flexibility, long-distance power transmission, or constant speed operation. Engineers must consider factors like load capacity, speed, maintenance needs, and cost-effectiveness before deciding on the most appropriate system. Both technologies have proven their worth in countless industries, highlighting the importance of understanding their unique characteristics to optimize system performance.

tapered shaft v belt pulley. V-belts also offer the advantage of being easily replaceable and adjustable, allowing for maintenance without disrupting the entire system.

While a tapered shaft offers superior strength and precision, it may require more complex manufacturing processes and can be less adaptable to changes in alignment. Conversely, V-belt pulley systems, though slightly less efficient in power transfer, provide flexibility and ease of maintenance. Their ability to accommodate misalignment makes them suitable for applications where perfect shaft alignment is difficult to achieve.

In conclusion, the choice between a tapered shaft and a V-belt pulley system largely depends on the specific requirements of the application. Tapered shafts excel in high-torque, precision-driven scenarios, while V-belt pulleys are ideal for systems needing flexibility, long-distance power transmission, or constant speed operation. Engineers must consider factors like load capacity, speed, maintenance needs, and cost-effectiveness before deciding on the most appropriate system. Both technologies have proven their worth in countless industries, highlighting the importance of understanding their unique characteristics to optimize system performance.

They are effective in applications where a constant speed is required, such as in HVAC systems, agricultural equipment, and conveyor belts They are effective in applications where a constant speed is required, such as in HVAC systems, agricultural equipment, and conveyor belts

They are effective in applications where a constant speed is required, such as in HVAC systems, agricultural equipment, and conveyor belts They are effective in applications where a constant speed is required, such as in HVAC systems, agricultural equipment, and conveyor belts tapered shaft v belt pulley. V-belts also offer the advantage of being easily replaceable and adjustable, allowing for maintenance without disrupting the entire system.

While a tapered shaft offers superior strength and precision, it may require more complex manufacturing processes and can be less adaptable to changes in alignment. Conversely, V-belt pulley systems, though slightly less efficient in power transfer, provide flexibility and ease of maintenance. Their ability to accommodate misalignment makes them suitable for applications where perfect shaft alignment is difficult to achieve.

In conclusion, the choice between a tapered shaft and a V-belt pulley system largely depends on the specific requirements of the application. Tapered shafts excel in high-torque, precision-driven scenarios, while V-belt pulleys are ideal for systems needing flexibility, long-distance power transmission, or constant speed operation. Engineers must consider factors like load capacity, speed, maintenance needs, and cost-effectiveness before deciding on the most appropriate system. Both technologies have proven their worth in countless industries, highlighting the importance of understanding their unique characteristics to optimize system performance.

tapered shaft v belt pulley. V-belts also offer the advantage of being easily replaceable and adjustable, allowing for maintenance without disrupting the entire system.

While a tapered shaft offers superior strength and precision, it may require more complex manufacturing processes and can be less adaptable to changes in alignment. Conversely, V-belt pulley systems, though slightly less efficient in power transfer, provide flexibility and ease of maintenance. Their ability to accommodate misalignment makes them suitable for applications where perfect shaft alignment is difficult to achieve.

In conclusion, the choice between a tapered shaft and a V-belt pulley system largely depends on the specific requirements of the application. Tapered shafts excel in high-torque, precision-driven scenarios, while V-belt pulleys are ideal for systems needing flexibility, long-distance power transmission, or constant speed operation. Engineers must consider factors like load capacity, speed, maintenance needs, and cost-effectiveness before deciding on the most appropriate system. Both technologies have proven their worth in countless industries, highlighting the importance of understanding their unique characteristics to optimize system performance. Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS