Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Understanding the Function and Benefits of a Take-Up Pulley System in Machinery

Understanding the Take-Up Pulley A Key Component in Conveyor Systems

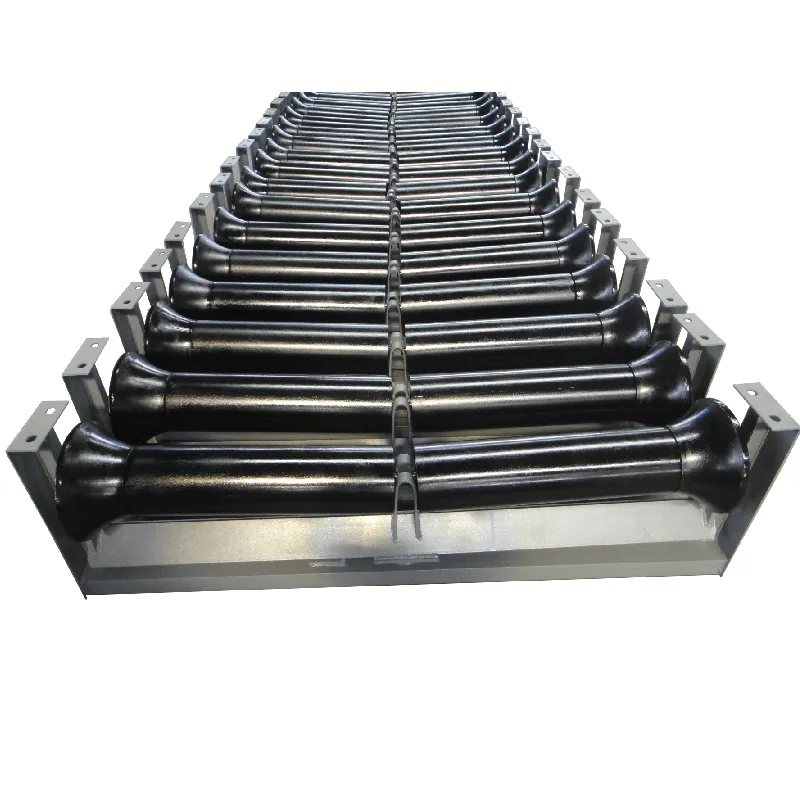

In the realm of industrial machinery and conveyor systems, efficiency and reliability are paramount. Among the various components that ensure optimal operation, the take-up pulley plays a crucial role. This article explores the significance of the take-up pulley, its design, functionality, and the benefits it brings to conveyor systems.

What is a Take-Up Pulley?

A take-up pulley is a mechanical device used in conveyor systems to maintain tension in the drive belt or chain. It is typically located at the end of the conveyor system and is adjustable, allowing operators to manipulate the tension to ensure smooth operation. The take-up pulley functions to manage the slack in the conveyor belt, which can occur due to several factors, including wear, stretch, or changes in load.

The Design and Functionality of Take-Up Pulleys

Take-up pulleys can vary in design, but they generally consist of a cylindrical shape mounted on a frame. The frame allows for movement, enabling the pulley to adjust its position and maintain consistent tension on the belt. This can be achieved through various mechanisms, such as screw adjustments, hydraulic systems, or spring-loaded designs.

The primary function of the take-up pulley is to keep the conveyor belt taut. A loose belt can lead to slippage, inefficient operation, and even potential damage to the conveyor system. By keeping the belt tensioned, the take-up pulley ensures that the conveyor operates smoothly and at optimal efficiency.

Importance in Conveyor Systems

take up pulley

The importance of the take-up pulley cannot be overstated. In industrial applications where heavy materials are transported, the constant load can cause the conveyor belt to stretch over time. If not monitored and adjusted, this can lead to severe operational issues, including misalignment and increased wear on the belt and other components.

1. Improved Performance By maintaining the right amount of tension, the take-up pulley enhances the overall performance of the conveyor system. A properly tensioned belt ensures that materials are moved efficiently, reducing downtime and improving productivity.

2. Extended Lifespan of Components An optimally tensioned conveyor belt minimizes excessive wear and tear. This not only prolongs the life of the belt but also protects other components in the system, such as bearings and motors, from undue stress and potential failure.

3. Energy Efficiency A well-maintained, tensioned system operates more efficiently, which can result in lower energy consumption. This translates to cost savings for companies that rely heavily on conveyor systems for their operations.

4. Safety Operating a conveyor system with a loose or sagging belt can pose safety risks. The take-up pulley helps mitigate this risk by ensuring that the belt remains properly tensioned, reducing the chances of unexpected slippage or misalignment that could lead to accidents.

Conclusion

In conclusion, the take-up pulley is a vital component of conveyor systems, playing an essential role in ensuring efficient and safe operation. Its ability to maintain tension in the conveyor belt prevents common issues associated with belt slackness, which can lead to operational inefficiencies and increased maintenance costs. By understanding the importance of the take-up pulley, businesses can invest in better maintenance practices and enhance the performance and longevity of their conveyor systems. As industries continue to evolve, the take-up pulley will remain a key technology ensuring that materials are transported effectively and reliably within the production process.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025