Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Understanding the Functionality and Importance of Take-Up Pulleys in Mechanical Systems

The Importance of Take-Up Pulleys in Mechanical Systems

Take-up pulleys play a vital role in various mechanical systems, especially in conveyor systems and continuous production lines. These specialized components are designed to maintain the proper tension in a belt, chain, or cable system, ensuring smooth operation and preventing slippage. Their significance cannot be overstated, as they impact efficiency, safety, and longevity of the equipment in which they are employed.

One of the primary functions of a take-up pulley is to adjust the tension in a belt. Over time, belts can experience wear and tear, leading to elongation and loss of tension. If the tension is not adequately maintained, it can result in a range of issues, such as reduced efficiency, increased energy consumption, and even catastrophic system failures. A properly functioning take-up pulley allows for easy adjustments, absorbing slack and ensuring optimal performance.

Take-up pulleys are commonly used in a variety of industries, from manufacturing to mining. For example, in a manufacturing setting, if a conveyor belt that moves products along an assembly line loses tension, it could cause jams or delays, impacting overall productivity. By incorporating take-up pulleys, operators can quickly adjust belt tension, keeping the line running smoothly and efficiently.

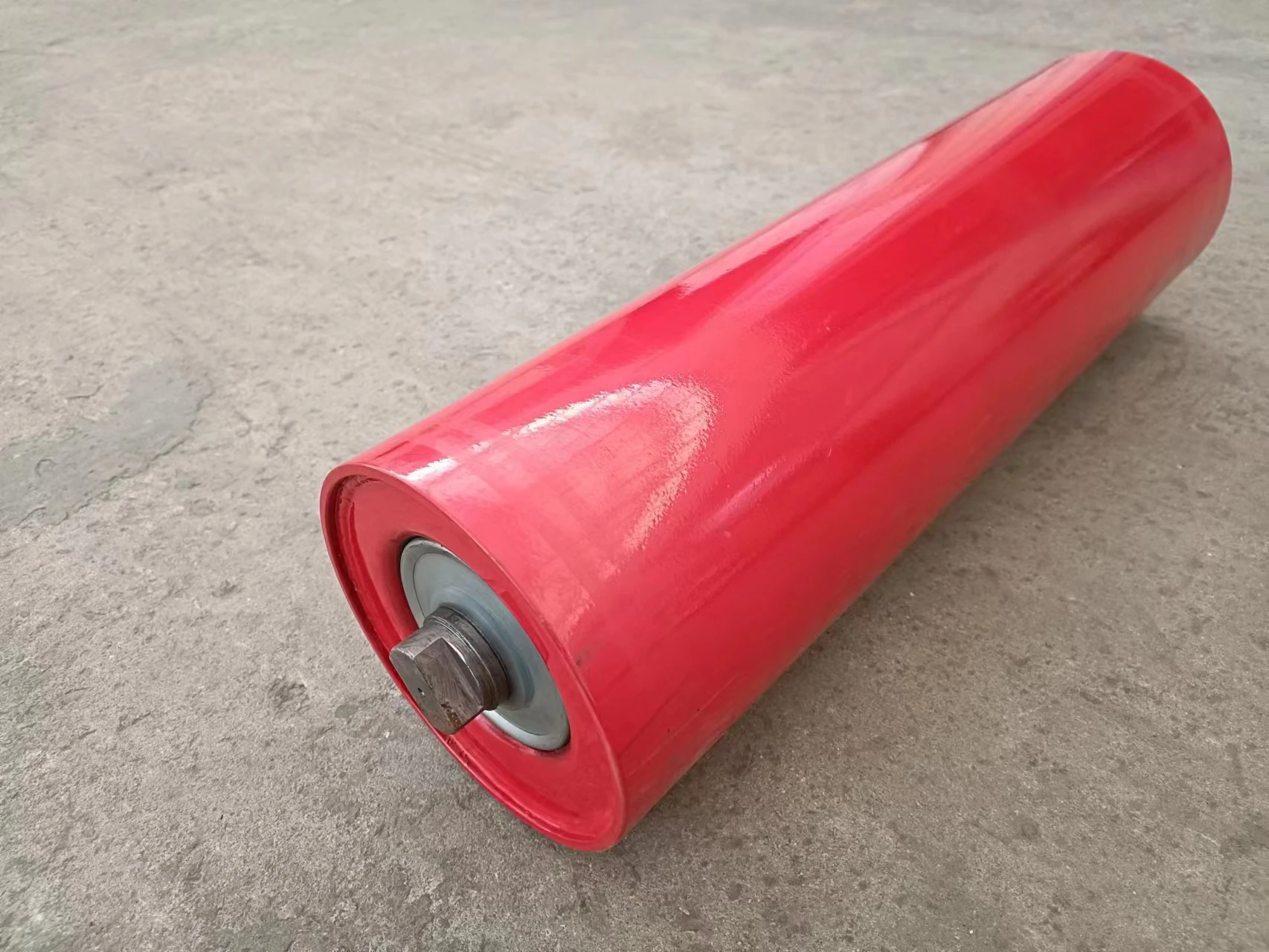

take-up pulley

Additionally, take-up pulleys contribute to the safety of mechanical systems. A loose belt can slip off the pulley, posing serious risks to personnel and equipment. This can lead to workplace injuries or costly downtime. By maintaining the correct tension, take-up pulleys help reduce these risks, providing a safer working environment and minimizing the chances of equipment failure.

Moreover, take-up pulleys also promote the longevity of the entire system. Consistent tension helps to prevent undue wear on belts and other components, thus extending their lifespan. Regular maintenance and adjustment using take-up pulleys can save companies significant amounts of money in replacement parts and labor, making them a wise investment.

When selecting a take-up pulley, various factors should be considered, including the type of belt, load capacity, and operational environment. Different applications may require specific designs or materials to withstand varying levels of stress and environmental conditions. Therefore, it is essential for engineers and technicians to carefully choose the appropriate take-up pulley.

In conclusion, take-up pulleys are integral components in mechanical systems that require tension management. Their ability to maintain optimal tension enhances efficiency, promotes safety, and extends the lifespan of equipment. As industries continue to evolve and demand higher efficiency, the importance of take-up pulleys will only increase, solidifying their place as essential elements in modern mechanical design.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025