Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu tail pulley

The Importance of Tail Pulleys in Conveyor Systems

In various industrial applications, conveyor systems play a critical role in efficiently transporting materials from one point to another. Among the numerous components that make up these systems, the tail pulley is often overlooked but is essential for the safe and effective operation of belt conveyors. Understanding the tail pulley’s function, design, and maintenance can greatly enhance conveyor performance and longevity.

What is a Tail Pulley?

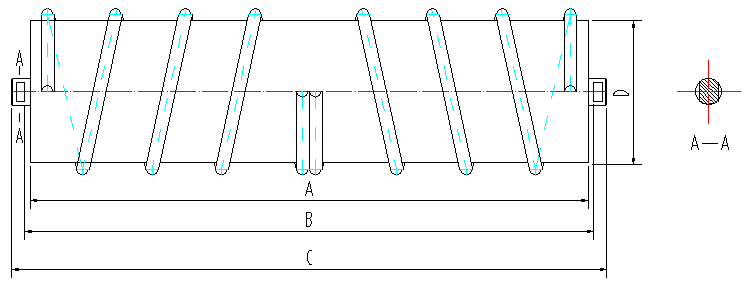

A tail pulley is an integral component of a conveyor system, situated at the downstream or discharge end of the belt. It serves multiple purposes, including supporting the weight of the returning belt, providing a surface for the belt to run on, and facilitating the tension required for effective material handling. Tail pulleys can be found in various shapes and sizes, tailored to meet the specific demands of different conveyor applications.

Function of Tail Pulleys

The primary function of the tail pulley is to maintain proper tension in the conveyor belt. This tension is vital to prevent slippage, ensuring smooth material transfer. The tail pulley also aids in the alignment of the belt, helping to reduce wear and tear and prolonging the service life of the conveyor system.

Moreover, tail pulleys contribute to the overall safety of the conveyor operation. A well-designed tail pulley minimizes the risk of belt misalignment, which can lead to accidents, equipment damage, and production downtimes. By ensuring the belt tracks correctly, the tail pulley plays a significant role in maintaining the efficiency of material transport.

Design Considerations

The design of tail pulleys involves careful consideration of various factors, including the type of material being transported, the environmental conditions, and the conveyor's operational requirements

. Tail pulleys are typically made from robust materials like steel to withstand the high stresses associated with heavy loads and continuous operation.tail pulley

Additionally, there are different types of tail pulleys, such as flat or crowned pulleys. Flat pulleys are commonly used in applications where precise belt tracking is essential, while crowned pulleys help to automatically align the belt, reducing the risk of lateral movement.

Maintenance of Tail Pulleys

Routine maintenance of tail pulleys is crucial to ensure their functionality and to extend the lifespan of the conveyor system. Regular inspections should focus on examining for signs of wear, misalignment, and proper tension. Any issues detected early can be addressed, thus preventing more significant problems in the future.

Lubrication is another essential part of tail pulley maintenance. Bearings typically require regular lubrication to ensure smooth operation, which helps in reducing friction and heat build-up. Over time, contaminants can accumulate in the lubricating grease, so it is important to replace it according to the manufacturer’s recommendations.

Technological Advances

Innovations in conveyor technology have also impacted the design and function of tail pulleys. Modern tail pulleys may incorporate features such as self-aligning designs, enhanced materials for improved durability, and even sensors that monitor the belt’s condition in real-time. These advancements enable operators to maintain higher efficiency levels and reduce unexpected downtimes.

Conclusion

In conclusion, the tail pulley is a crucial component of conveyor systems that often does not receive the recognition it deserves. Its contribution to maintaining belt tension, alignment, and safety is indispensable in various industries, from mining to manufacturing. To maximize the efficiency and reliability of conveyor operations, attention must be given to the design, maintenance, and technological enhancements of tail pulleys. By recognizing their importance, operators can ensure smoother operations and mitigate potential issues, ultimately leading to greater productivity and safety in their industrial processes.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025