Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Understanding Tail Drum Pulley Mechanics and Applications in Conveyor Systems

Understanding Tail Drum Pulleys Essential Components in Conveyor Systems

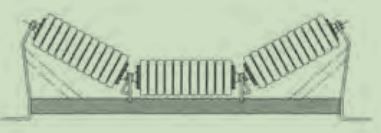

In industrial settings, efficiency and reliability are paramount. Among the many components that contribute to the smooth operation of conveyor systems, the tail drum pulley plays a vital role. This article will explore the function, design, and importance of tail drum pulleys in conveyor systems, showcasing why they are indispensable in various applications.

What is a Tail Drum Pulley?

A tail drum pulley is a specific type of pulley located at the end of a conveyor system. It serves several essential purposes 1. Support the Conveyor Belt The tail drum pulley provides structural support and anchors the conveyor belt at its termination point. 2. Redirection of the Belt It helps in redirecting the conveyor belt back to the head pulley, ensuring continuous movement and operation. 3. Tensioning The tail drum plays a crucial role in maintaining proper belt tension, which is critical for efficient operation and longevity of the belt.

Key Functions and Importance

The importance of tail drum pulleys can be summarized in several key functions

1. Belt Tracking and Alignment Properly aligned tail drum pulleys help in maintaining the correct path of the conveyor belt. Misalignment can lead to wear and tear, decrease in efficiency, and could even damage the belt and pulleys.

2. Load Distribution The tail drum is designed to distribute the weight of the conveyed materials evenly across the belt. This helps prevent excessive wear on specific areas of the belt, thereby extending its life span.

3. Belt Tension Maintenance A tail drum pulley also aids in keeping the belt tension at an optimal level. If the belt is too loose, it may slip, leading to inefficiencies and potential stoppages. Conversely, too much tension can result in the belt breaking or excessive wear on components.

Design Considerations

tail drum pulley

When selecting or designing a tail drum pulley, several factors must be considered to ensure optimal performance

1. Material Selection Tail drum pulleys are often made from robust materials such as steel or aluminum to withstand heavy loads and the harsh operating environments commonly found in industrial settings.

2. Size and Diameter The size of the pulley will affect the belt's operating speed and tension. A larger diameter pulley can help reduce belt wear, while smaller diameters may lead to increased friction.

3. Coatings and Treatments To improve durability and resistance to corrosion, pulleys may undergo various coatings or treatments. This is particularly important in environments where exposure to moisture, chemicals, or extreme temperatures is common.

4. Bearing Systems The selection of bearings is crucial as they need to handle heavy loads and varying speeds. Quality bearings will reduce friction and improve the overall efficiency of the conveyor system.

Maintenance and Upkeep

Regular maintenance of tail drum pulleys is essential for ensuring their longevity and reliable operation. This includes - Inspecting for wear and tear Regular checks can identify potential issues before they become severe. - Lubrication Ensuring that bearings are adequately lubricated helps reduce friction and prolongs their life. - Alignment checks Ensuring that the tail drum pulley is correctly aligned with the conveyor system can prevent many operational issues.

Conclusion

In conclusion, tail drum pulleys are crucial components of conveyor systems that contribute significantly to their overall efficiency and reliability. By understanding their functions, importance, and maintenance needs, industries can ensure that their conveyor systems operate smoothly and efficiently. Investing in high-quality tail drum pulleys, along with regular maintenance, will lead to increased longevity of the conveyor system and reduction in operational costs, making them a wise choice for businesses across various sectors.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025