Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu High-Performance Return Rollers for Enhanced Conveyor System Efficiency and Durability

Understanding Superior Return Rollers Enhancing Conveyor Systems Efficiency

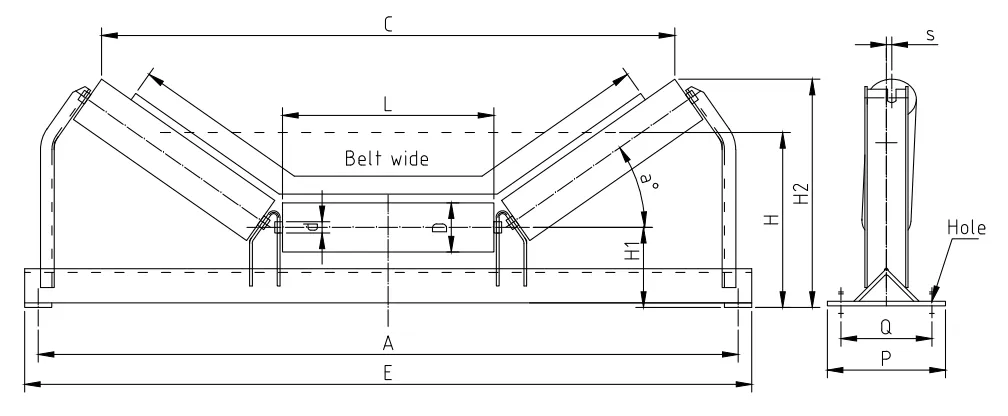

In the realm of industrial operations, conveyor systems play a pivotal role in ensuring the seamless movement of materials. Among the essential components of these systems are return rollers, which significantly impact the efficiency and reliability of the entire conveyor setup. Superior return rollers, designed with advanced engineering and materials, are crucial for optimizing performance and minimizing downtime.

Return rollers serve as a fundamental part of belt conveyors, facilitating the return of the conveyor belt from the discharge point back to the loading area. High-quality return rollers reduce friction and wear, enhancing the lifespan of the conveyor belt and the associated machinery. When we talk about superior return rollers, we refer to those that exhibit outstanding durability, reduced operational noise, lower energy consumption, and exceptional resistance to harsh environmental conditions.

One of the key advantages of superior return rollers is their impact on operational efficiency. Traditional rollers may generate excessive friction, leading to increased energy consumption and potential overheating. In contrast, superior return rollers, often equipped with precision bearings and designed with superior alignment mechanisms, ensure smoother belt operation. This reduction in friction not only saves energy but also minimizes wear on the belt, resulting in prolonged service life and lower maintenance costs.

superior return rollers

Moreover, superior return rollers are often crafted from advanced materials that resist corrosion and abrasion, making them suitable for various applications ranging from mining and quarrying to food processing and packaging. The choice of high-quality materials ensures that these rollers can withstand the rigors of heavy-duty use, providing consistent performance in challenging conditions.

Another critical aspect of return rollers is their role in maintaining belt alignment. Misalignment can lead to belt damage, material spillage, and increased maintenance requirements. Superior return rollers are engineered to provide optimal tracking and alignment, reducing the chances of misalignment-related issues. This feature is particularly beneficial in applications where precise material handling is essential.

In conclusion, superior return rollers represent a significant advancement in conveyor technology. They enhance efficiency, minimize operational costs, and improve the overall reliability of conveyor systems. By investing in high-quality return rollers, industries can optimize their operations, ensuring that their material handling processes remain smooth, efficient, and cost-effective. As industries continue to evolve, the importance of superior return rollers will only grow, making them an indispensable component of modern conveyor systems.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025