Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 26, 2025 07:47

Back to list

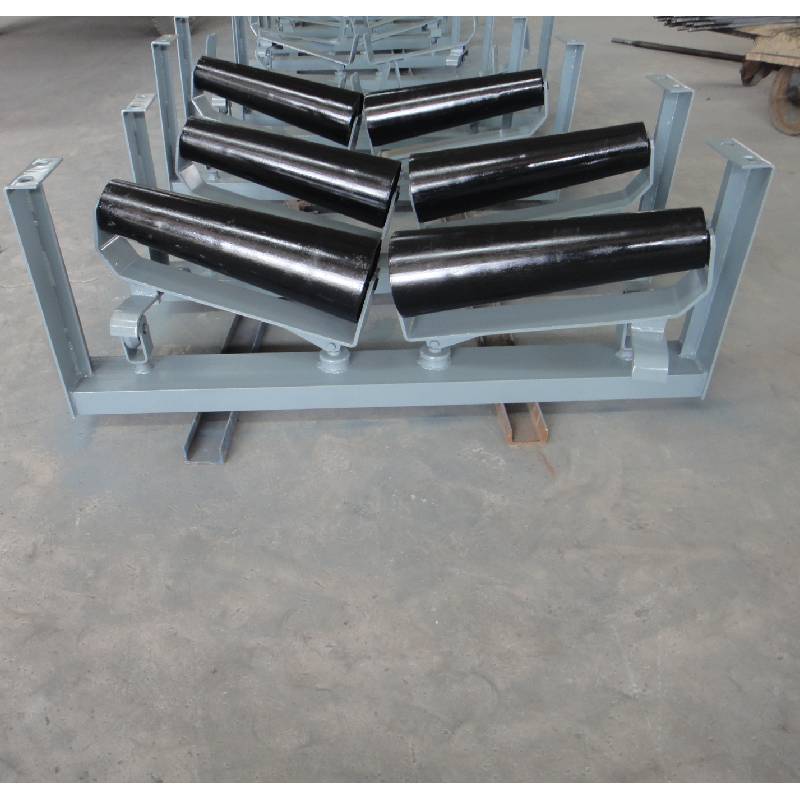

Troughing Roller

Superior conveyor rollers are revolutionizing the material handling industry by setting new standards in efficiency, durability, and reliability. Designed with cutting-edge materials and engineering expertise, these rollers are becoming essential components in various sectors such as logistics, mining, and manufacturing. This article explores the exceptional qualities of superior conveyor rollers, their applications, and their impact on operational efficiency.

The authority of superior conveyor rollers is evident in their widespread adoption across various sectors. In logistics, these rollers are integral for automating warehouse operations, facilitating the seamless transportation of packages and pallets. In the mining industry, they withstand extreme conditions, transporting minerals and ores with high efficiency and reliability. Manufacturing plants rely on superior rollers for assembly lines and production facilities, where precision and speed are essential. This widespread usage underlines their reputation and reliability as critical components in modern material handling solutions. Trust in the performance of superior conveyor rollers is reinforced by the positive feedback and endorsements from industry experts and businesses alike. Many companies report significant enhancements in operational speed, reliability, and reduced maintenance requirements after integrating these rollers into their systems. This trust is further solidified by customer support teams that offer comprehensive assistance, ensuring that clients receive the optimal setup and ongoing maintenance for their roller systems. The focus on building long-term relationships with clients demonstrates the commitment to delivering quality and trustworthy products. Investing in superior conveyor rollers is not merely an upgrade; it is a strategic enhancement that aligns with modern demands for efficiency and reliability. By choosing products that embody experience, expertise, authority, and trustworthiness, businesses can significantly enhance their operational capabilities and maintain a competitive edge in their respective industries. Superior conveyor rollers represent a forward-thinking approach to material handling, providing robust solutions for an increasingly automated and fast-paced industrial world. Whether for a small warehouse or a large-scale mining operation, these rollers are the backbone of efficient material flow, guaranteeing optimal performance and satisfaction. Embracing this technology is a step towards a future where operational efficiency is not just a goal but a standard expectation.

The authority of superior conveyor rollers is evident in their widespread adoption across various sectors. In logistics, these rollers are integral for automating warehouse operations, facilitating the seamless transportation of packages and pallets. In the mining industry, they withstand extreme conditions, transporting minerals and ores with high efficiency and reliability. Manufacturing plants rely on superior rollers for assembly lines and production facilities, where precision and speed are essential. This widespread usage underlines their reputation and reliability as critical components in modern material handling solutions. Trust in the performance of superior conveyor rollers is reinforced by the positive feedback and endorsements from industry experts and businesses alike. Many companies report significant enhancements in operational speed, reliability, and reduced maintenance requirements after integrating these rollers into their systems. This trust is further solidified by customer support teams that offer comprehensive assistance, ensuring that clients receive the optimal setup and ongoing maintenance for their roller systems. The focus on building long-term relationships with clients demonstrates the commitment to delivering quality and trustworthy products. Investing in superior conveyor rollers is not merely an upgrade; it is a strategic enhancement that aligns with modern demands for efficiency and reliability. By choosing products that embody experience, expertise, authority, and trustworthiness, businesses can significantly enhance their operational capabilities and maintain a competitive edge in their respective industries. Superior conveyor rollers represent a forward-thinking approach to material handling, providing robust solutions for an increasingly automated and fast-paced industrial world. Whether for a small warehouse or a large-scale mining operation, these rollers are the backbone of efficient material flow, guaranteeing optimal performance and satisfaction. Embracing this technology is a step towards a future where operational efficiency is not just a goal but a standard expectation.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS