Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 14, 2025 09:55

Back to list

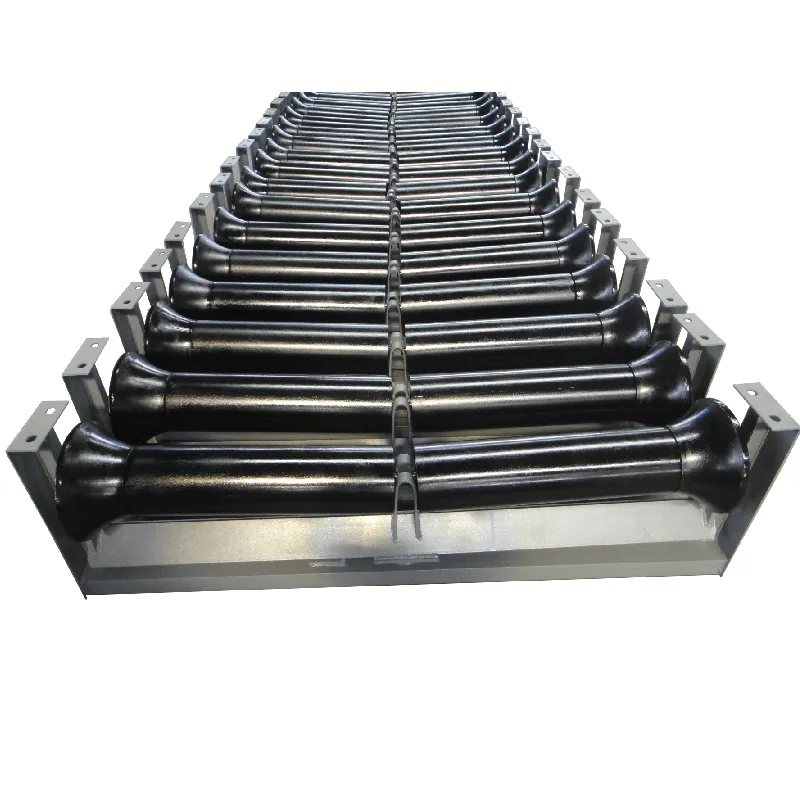

steel guide roller

Steel guide rollers are integral components in an array of industrial applications, providing crucial guidance to conveyor systems, machinery, and various equipment involved in high-stakes production environments. The importance of using reliable, expertly crafted steel guide rollers cannot be overstated, as they play a pivotal role in ensuring operational efficiency, safety, and durability.

The application-specific design is another dimension that cannot be ignored. Steel guide rollers must be customized to suit the specific operational needs of their applications. For instance, they may need to accommodate different load capacities, speeds, or directional changes in material handling systems. Customized rollers provide an optimized fit that not only boosts equipment performance but also enhances safety by reducing the risk of system failures. Trust in manufacturers and suppliers is paramount when sourcing steel guide rollers. Established brands and suppliers with a track record of delivering high-quality, reliable components provide an assurance of expertise and credibility. They often offer comprehensive technical support and guidance, which facilitates the selection of the best-suited rollers for specific industrial applications. One such critical element in ensuring the reliability of steel guide rollers lies in consistent quality checks and adherence to international standards. Manufacturers with ISO certifications and robust quality management systems are capable of providing products that consistently meet or exceed expectations and comply with regulatory requirements. In summary, steel guide rollers might seem like a minute component in complex industrial machinery, but their impact is profound. Prioritizing quality material, precision engineering, customized design, and reputable sourcing will not only enhance operational efficiency but also contribute significantly to the longevity and safety of industrial systems. Investing in top-tier steel guide rollers is not just a purchase, but a commitment to sustained excellence and reliability in industrial operations.

The application-specific design is another dimension that cannot be ignored. Steel guide rollers must be customized to suit the specific operational needs of their applications. For instance, they may need to accommodate different load capacities, speeds, or directional changes in material handling systems. Customized rollers provide an optimized fit that not only boosts equipment performance but also enhances safety by reducing the risk of system failures. Trust in manufacturers and suppliers is paramount when sourcing steel guide rollers. Established brands and suppliers with a track record of delivering high-quality, reliable components provide an assurance of expertise and credibility. They often offer comprehensive technical support and guidance, which facilitates the selection of the best-suited rollers for specific industrial applications. One such critical element in ensuring the reliability of steel guide rollers lies in consistent quality checks and adherence to international standards. Manufacturers with ISO certifications and robust quality management systems are capable of providing products that consistently meet or exceed expectations and comply with regulatory requirements. In summary, steel guide rollers might seem like a minute component in complex industrial machinery, but their impact is profound. Prioritizing quality material, precision engineering, customized design, and reputable sourcing will not only enhance operational efficiency but also contribute significantly to the longevity and safety of industrial systems. Investing in top-tier steel guide rollers is not just a purchase, but a commitment to sustained excellence and reliability in industrial operations.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS