Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

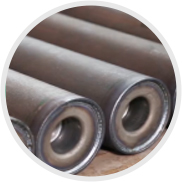

Zulu steel guide roller

Understanding Steel Guide Rollers A Comprehensive Overview

Steel guide rollers are essential components widely used in various industrial applications, including manufacturing, construction, and transportation. Their primary function is to facilitate the smooth movement of machinery, conveyor belts, and other mechanical systems. This article delves into the significance, types, materials, and applications of steel guide rollers, shedding light on why they are vital to modern industrial operations.

Importance of Steel Guide Rollers

The primary purpose of steel guide rollers is to reduce friction and wear in mechanical systems. By providing a smooth and stable surface for dynamic loads, these rollers improve the efficiency and longevity of machinery. In industries where precision and reliability are paramount, such as automotive manufacturing or packaging, steel guide rollers play a critical role in ensuring uninterrupted operations.

Moreover, the load-bearing capabilities of steel guide rollers allow them to support substantial weights, which is particularly significant in heavy-duty applications. Their strength and durability mean that they can withstand harsh operating environments, including extreme temperatures and exposure to corrosive substances.

Types of Steel Guide Rollers

Steel guide rollers can be categorized based on several factors, including design, application, and the type of bearing used. Here are the most common types

1. Flat Guide Rollers These rollers have a flat surface and are typically used for guiding conveyor belts. Their design minimizes wear on both the roller and the belt, leading to reduced maintenance needs.

2. V-Groove Rollers Shaped like a “V,” these rollers are ideal for guiding tracks and lines. They help maintain alignment, ensuring that machinery operates accurately and efficiently.

3. Heavy-Duty Rollers Designed for extreme conditions, heavy-duty steel guide rollers are made to handle significant loads and provide stability in rugged environments. These rollers are used in applications ranging from construction equipment to large industrial machines.

4. Adjustable Rollers These rollers allow for height and position adjustments, making them versatile in various applications. Their adaptability provides a solution for machines requiring precise movements due to changing conditions.

Material Considerations

Steel guide rollers are made from various steel grades, each offering different properties suited to specific applications

. Common materials includesteel guide roller

- Carbon Steel Known for its durability and strength, carbon steel is often used in general-purpose guide rollers.

- Stainless Steel The corrosion resistance of stainless steel makes it suitable for environments exposed to moisture or chemicals. This type of roller is prevalent in food processing and pharmaceutical industries.

- Alloy Steel Alloy steel offers superior strength and toughness, making it ideal for heavy-duty applications that require high performance under challenging conditions.

The choice of material impacts the roller's performance, resistance to wear, and overall lifespan. Manufacturers often employ a combination of materials and coatings to enhance durability and performance further.

Applications of Steel Guide Rollers

Steel guide rollers find applications across various industries due to their versatility. Some notable examples include

1. Automotive Manufacturing Rollers are extensively used in assembly lines to ensure that parts are guided smoothly from one station to another, enhancing productivity and precision.

2. Conveyor Systems In warehouses and logistics, guide rollers assist conveyor belts in transporting goods efficiently, reducing downtime and energy consumption.

3. Construction Equipment Steel guide rollers are integral to equipment like cranes and excavators, where they ensure proper alignment and movement of heavy loads.

4. Packaging Machinery These rollers help guide films, boxes, and containers through packaging lines, ensuring that products are packaged accurately and efficiently.

5. Textile Industry In textile manufacturing, guide rollers are used to manage the movement of fabrics through multiple stages of production, thus maintaining quality and reducing wastage.

Conclusion

As industries continue to evolve and demand greater efficiency, the importance of components like steel guide rollers cannot be overstated. Their ability to reduce friction, support heavy loads, and adapt to various applications makes them indispensable in modern machinery and manufacturing processes. Understanding their types, materials, and applications can help businesses make informed decisions when selecting the appropriate rollers for their operations. As technology advances, it is likely we will see continued innovations in the design and materials used for steel guide rollers, further enhancing their capabilities in the industrial sector.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025