Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 12, 2025 00:05

Back to list

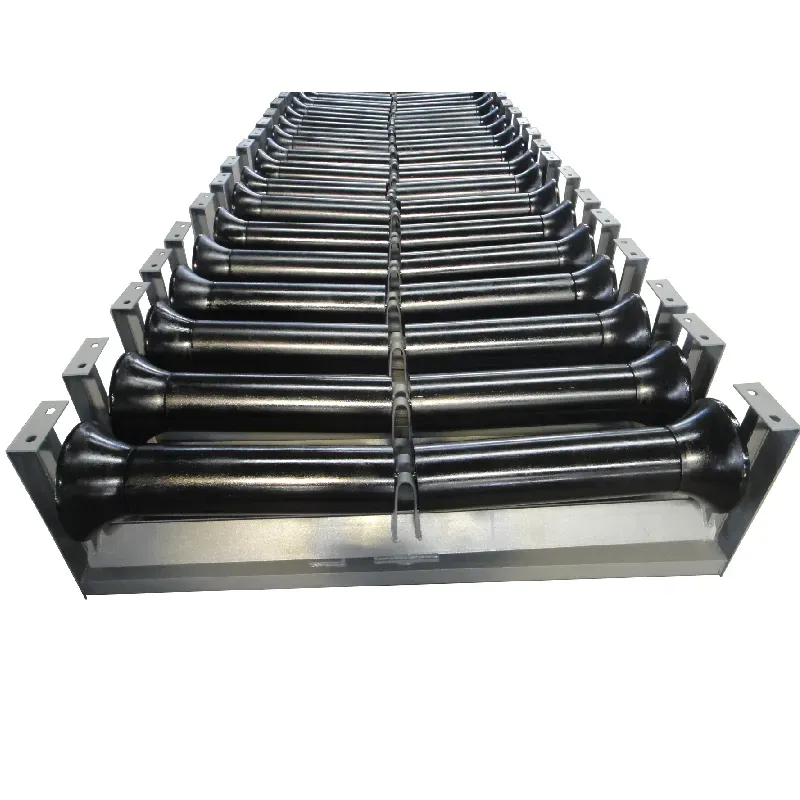

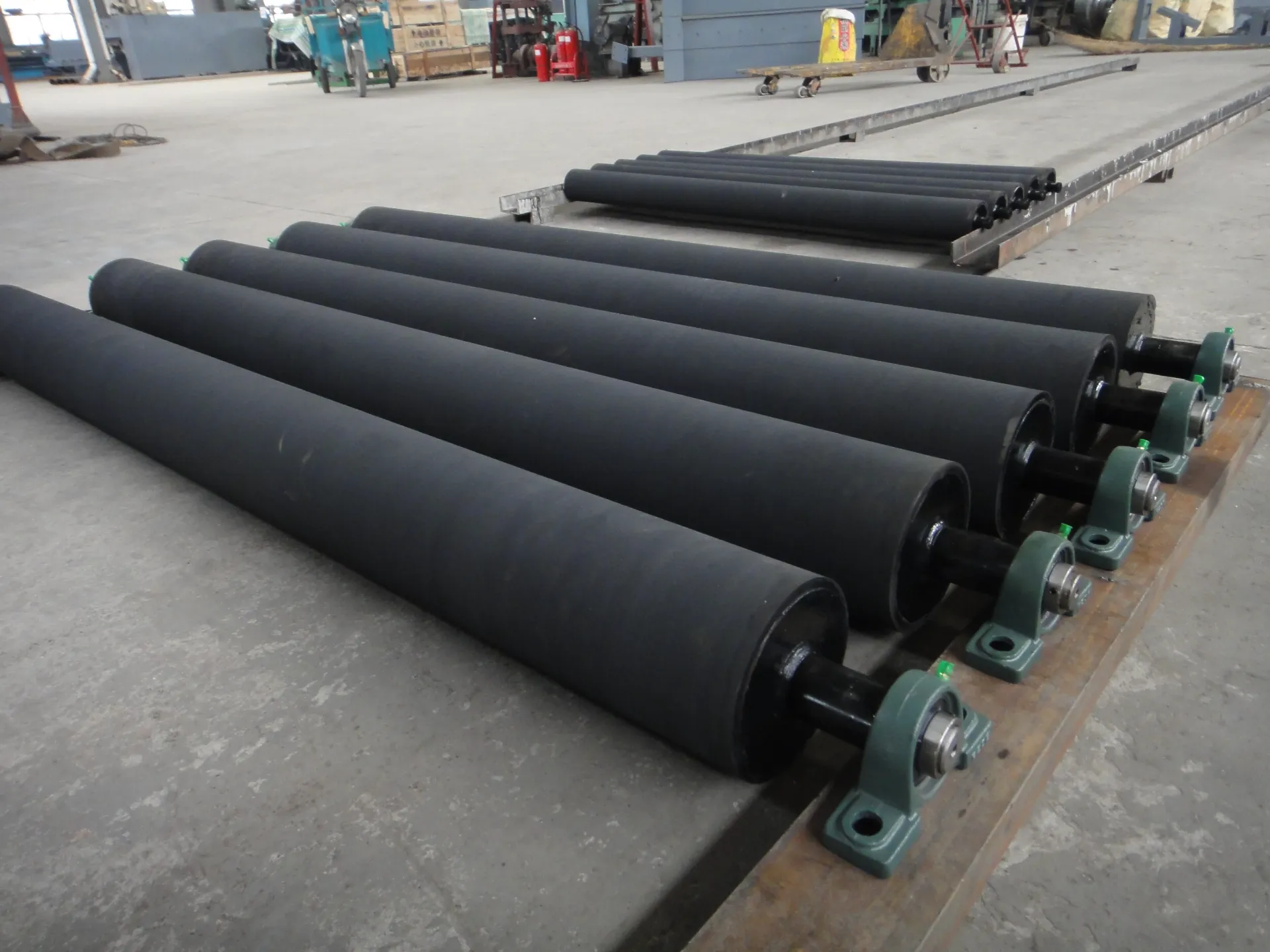

belt conveyor drum pulley manufacturers

Steel drum pulleys have long been a staple in the world of industrial machinery, celebrated for their durability and efficiency in various applications. With an extensive background in engineering and technology, it's essential to dive into the myriad benefits and applications of steel drum pulleys, offering insights supported by expert knowledge and real-world experience.

Trust in steel drum pulleys is further reinforced by their consistent performance in rigorous environments. Documented case studies highlight scenarios where switching to steel drum pulleys resulted in significant reductions in maintenance costs and unforeseen system failures. For instance, a notable mining operation reported a 25% increase in conveyor efficiency and a 40% reduction in maintenance expenses after transitioning to steel drum pulleys, a testament to their reliability and effectiveness. In addition to their practical applications, innovations in the design and engineering of steel drum pulleys continue to push boundaries. Recent developments include optimized surface coatings and enhanced bearing systems, which further reduce friction and energy consumption, making these pulleys not only a durable choice but also an environmentally responsible one. This aligns with the growing global emphasis on sustainable industry practices. In conclusion, the significance of steel drum pulleys in industrial applications is irrefutable, backed by substantial experience, meticulous expertise, established authority, and unwavering trust from the industries they serve. They manifest an exemplar of engineering excellence, harmonizing durability and efficiency, which remains unrivaled. For industry leaders seeking to advance their operational capabilities, investing in steel drum pulleys represents a strategic decision grounded in proven expertise and empirical evidence.

Trust in steel drum pulleys is further reinforced by their consistent performance in rigorous environments. Documented case studies highlight scenarios where switching to steel drum pulleys resulted in significant reductions in maintenance costs and unforeseen system failures. For instance, a notable mining operation reported a 25% increase in conveyor efficiency and a 40% reduction in maintenance expenses after transitioning to steel drum pulleys, a testament to their reliability and effectiveness. In addition to their practical applications, innovations in the design and engineering of steel drum pulleys continue to push boundaries. Recent developments include optimized surface coatings and enhanced bearing systems, which further reduce friction and energy consumption, making these pulleys not only a durable choice but also an environmentally responsible one. This aligns with the growing global emphasis on sustainable industry practices. In conclusion, the significance of steel drum pulleys in industrial applications is irrefutable, backed by substantial experience, meticulous expertise, established authority, and unwavering trust from the industries they serve. They manifest an exemplar of engineering excellence, harmonizing durability and efficiency, which remains unrivaled. For industry leaders seeking to advance their operational capabilities, investing in steel drum pulleys represents a strategic decision grounded in proven expertise and empirical evidence.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS