Steel Bearing Housing Design and Applications in Modern Machinery and Equipment

Understanding Steel Bearing Housing Its Importance and Applications

Steel bearing housing is a pivotal component in various machinery and equipment, serving as the sturdy structure that supports and houses bearings. Bearings are essential for reducing friction between moving parts and facilitating smooth motion in machines, making the selection of appropriate housing critical. This article delves into the significance, design features, materials, and applications of steel bearing housings.

The Importance of Steel Bearing Housing

The primary function of bearing housing is to provide a stable and robust support structure for bearings, ensuring they remain aligned and secure under operational conditions. Steel bearing housings are particularly favored due to their strength, durability, and resistance to deformation. These characteristics make them ideal for applications involving heavy loads and high speeds, where the integrity of the bearing assembly is crucial.

In industrial settings, the reliability of machinery is paramount. A well-designed bearing housing reduces the risk of misalignment, overheating, and premature wear of bearings. This ultimately leads to lower maintenance costs, reduced downtime, and extended equipment lifespan. Additionally, steel bearing housings can often withstand extreme environmental conditions, further enhancing their practicality in diverse settings.

Design Features

Steel bearing housings come in various designs to accommodate different types of bearings and installation requirements. Common styles include pillow blocks, flange mounts, and take-up housings. Each design has its advantages, enabling engineers to select the most suitable option based on specific operational demands.

Several key design features characterize high-quality steel bearing housings

1. Material Quality Typically made from high-grade carbon steel or stainless steel, these housings provide superior strength and corrosion resistance. The material choice impacts not only mechanical properties but also resistance to specific environmental factors.

2. Precision Machining To ensure proper fit and alignment, steel bearing housings are often machined with high precision. This minimizes the risk of vibration and noise, enhancing the operational efficiency of the machinery.

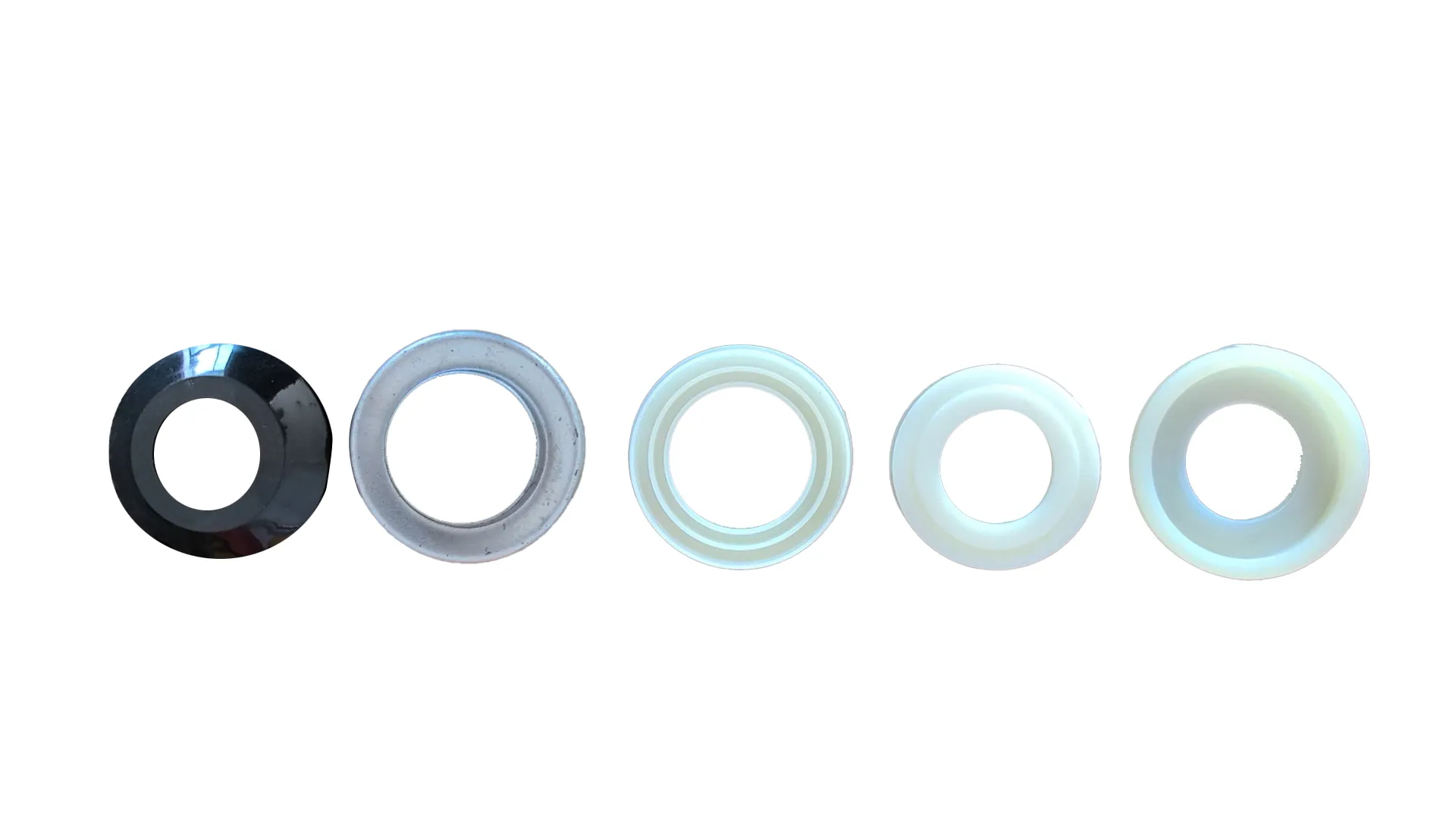

steel bearing housing

3. Lubrication Systems Many steel bearing housings incorporate built-in lubrication systems or provisions for grease fittings. Proper lubrication is essential for maintaining bearing performance and longevity, making this feature crucial in enhancing functionality.

4. Sealing Options Effective sealing mechanisms can protect against contaminants such as dust, dirt, and moisture, which can compromise bearing performance. Steel housings often include labyrinth seals or lip seals to safeguard the internal components.

Applications in Various Industries

Steel bearing housings are widely used across multiple industries due to their versatility and reliability. Some common applications include

- Manufacturing In production lines, these housings support conveyor systems and robotic arms, ensuring smooth operation and minimizing wear and tear on moving parts.

- Automotive Steel bearing housings play a critical role in automotive assemblies, including wheel bearings and engine components, contributing to vehicle performance and safety.

- Mining and Agriculture The robustness of steel bearing housings makes them ideal for use in heavy machinery, such as excavators and tractors, where they endure harsh conditions and significant loads.

- Food Processing In environments requiring high hygiene standards, stainless steel bearing housings are employed to support equipment while resisting corrosion and contamination.

Conclusion

Steel bearing housing serves as an indispensable element in the functionality and reliability of various machinery and equipment. Its durability, precision engineering, and adaptability make it a preferred choice across numerous industries. As technology advances, innovations in material science and engineering will likely enhance the design and performance capabilities of steel bearing housings even further, ensuring they remain a fundamental part of mechanical systems for years to come.

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025