Exploring the Dynamics of Beater Rollers in Modern Manufacturing

The Beater Roller Revolutionizing Industrial Processes

In the ever-evolving world of industrial machinery, the beater roller stands out as a vital component that enhances efficiency and productivity across various sectors. This ingenious invention, often found in food processing, packaging, and manufacturing industries, has redefined traditional methods and streamlined operations significantly.

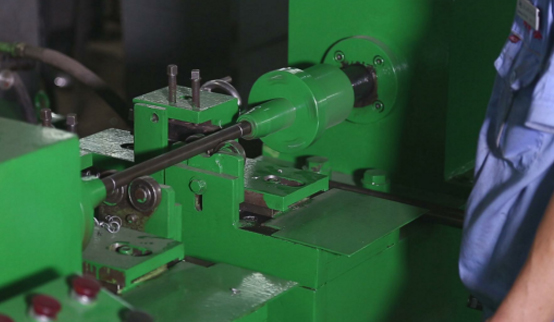

At its core, a beater roller consists of a cylindrical drum equipped with paddles or beaters that rotate at high speeds. This design allows it to mix, grind, or crush materials thoroughly, ensuring uniformity in the final product. The versatility of the beater roller makes it suitable for a wide array of applications, from kneading dough in bakeries to breaking down materials in recycling processes.

One of the primary advantages of using a beater roller is its ability to increase operational efficiency. In many production lines, time is of the essence. Traditional mixing and grinding methods can be labor-intensive and time-consuming. The beater roller, with its efficient design, reduces processing time significantly. For instance, in the food manufacturing sector, this machine can blend ingredients rapidly, ensuring that products are prepared timely without compromising on quality. This not only boosts productivity but also enhances the overall throughput of a manufacturing facility.

Furthermore, the beater roller’s design contributes to a consistent product quality. In industries where precision is crucial, such as pharmaceuticals and food production, maintaining uniformity in mixtures is paramount. The continuous operation of the beater roller guarantees that every batch is mixed to the same standard, reducing variability and ensuring that products meet stringent quality control standards. This predictability in production not only increases customer satisfaction but also helps companies maintain their reputations.

beater roller

In addition to efficiency and consistency, beater rollers are praised for their energy-efficient operation. Modern beater rollers are designed with energy consumption in mind, utilizing advanced technologies that minimize power usage without sacrificing performance. As industries are increasingly pressured to reduce their carbon footprint, investing in energy-efficient machinery like beater rollers becomes a strategic move. Companies that adopt these machines can experience lower operational costs and contribute positively to environmental sustainability efforts.

Moreover, the maintenance of beater rollers has been streamlined due to innovations in design. Many manufacturers incorporate features that make these machines easier to clean and maintain. This consideration not only ensures hygiene, especially in food-related processing, but also extends the lifespan of the equipment, further enhancing the return on investment.

Despite the numerous benefits, it’s important to note that businesses should assess their specific needs before incorporating a beater roller into their operations. Factors such as material type, desired output, and production volume play critical roles in determining the suitability of this machinery. A careful evaluation can lead to optimal machinery selection, enhancing overall productivity.

In conclusion, the beater roller represents a significant advancement in industrial processing equipment. Its blend of efficiency, consistency, and energy-saving qualities makes it an asset across various industries. As companies continue to seek ways to optimize production while maintaining high standards, the beater roller is likely to remain a central figure in the quest for operational excellence. Embracing such innovations is not just about keeping up with technology; it is about forging a path towards a more efficient and sustainable future in manufacturing.

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025

-

Idler Rollers for Belt Conveyors | Sealed Bearings, DurableNewsNov.17,2025

-

Polyurethane Pulley: Durable, Quiet, Conveyor-ReadyNewsNov.17,2025

-

Conveyor Bearing Housing | Precision Sealed Steel,Rubber,Plastic OEMNewsNov.17,2025

-

Vertical Roller: Heavy-Duty, Low-Noise, Sealed BearingsNewsNov.17,2025

-

Steel Flanging Bearing Housing for Conveyors – Durable, SealedNewsNov.17,2025