Spring Impact Idler-Yanshan Aohua|Conveyor Belt Protection&Durability

Product Overview

The Spring Impact Idler represents a significant advancement in conveyor belt technology, combining innovative engineering with practical design to address common challenges in material handling systems. This product, developed by Yanshan Aohua Machinery Equipment Manufacture Limited Company, offers a comprehensive solution for industries that rely on efficient and durable conveyor systems.

Figure 1: Spring Impact Idler in operational environment

Technical Specifications

| Parameter | Description |

|---|---|

| Product Name | Spring Impact Idler |

| Origin | Hebei Province, China |

| Brand | AOHUA |

| Standards | CEMA, ISO, DIN, JIS, DTII |

| Belt Width Range | 400-2400mm |

| Roller Diameter Range | 48-219mm |

| Axle Diameter Range | 17-60mm |

| Wall Thickness | 6-12mm (customizable) |

| Life Span | 30,000 hours |

| Coating Options | Electrostatic powder spraying, painting, hot-dip galvanizing |

| Bearing Brands | HRB, ZWZ, LYC, SKF, FAG, NSK |

Key Features and Advantages

The Spring Impact Idler distinguishes itself through its innovative design and advanced engineering. The system's core technology involves a pressure spring mechanism that acts as a dynamic cushioning system. This design allows the idler to adjust its elastic force based on the impact of materials, providing optimal protection for conveyor belts under varying operational conditions.

Figure 2: Internal spring mechanism

Figure 3: Adjustable trough angle design

Technical Innovation

The idler's unique feature is its ability to adjust the trough angle of the idler according to the belt height. This customization ensures that the middle idler maintains an optimal position relative to the belt, reducing material spillage and extending belt life. The system's patent (ZL94247277.2) highlights its superiority in protecting conveyor belts and minimizing material loss during operation.

Performance Benefits

- Enhanced belt protection through dynamic cushioning

- Reduced material spillage with adjustable design

- Extended service life of conveyor systems

- Adaptable to various belt widths and operational conditions

Applications in Industrial Settings

The Spring Impact Idler is designed for use in a wide range of industrial applications where conveyor systems are critical. Its robust construction and advanced features make it suitable for:

- Coal Mines: Handling abrasive materials with high impact forces

- Cement Plants: Managing heavy loads and corrosive environments

- Power Plants: Ensuring reliable operation in high-temperature conditions

- Steel Mills: Withstanding extreme mechanical stresses

- Recycling Industries: Processing mixed materials with varying densities

Figure 4: Industrial application scenarios

Company Background

Yanshan Aohua Machinery Equipment Manufacture Limited Company is a leading manufacturer of conveyor belt components based in Hebei Province, China. With years of experience in the industry, the company has established itself as a reliable provider of high-quality industrial equipment.

Manufacturing Capabilities

- Compliance with international standards (CEMA, ISO, etc.)

- Customizable solutions for specific client requirements

- Advanced welding techniques including robot welding and mixed gas arc welding

- Comprehensive after-sales support including online and video technical assistance

Quality Assurance

The company adheres to strict quality control measures, ensuring that all products meet the required standards. Their manufacturing process includes:

- Material standards Q235B and Q235A

- Electrostatic powder coating for durability

- Customizable color options to meet client preferences

- Secure packaging solutions including fumigation-free plywood boxes and iron frames

Industry Standards and Compliance

The Spring Impact Idler is designed to meet rigorous industry standards, ensuring its effectiveness in demanding environments. According to National Institute of Standards and Technology (NIST) guidelines, the product's design and manufacturing processes align with established benchmarks for industrial equipment:

"NIST's research on material standards and mechanical systems provides critical insights for manufacturers to ensure their products meet the highest quality and safety requirements." NIST Technical Report, 2023

This compliance ensures that the Spring Impact Idler not only meets but exceeds industry expectations for performance and reliability.

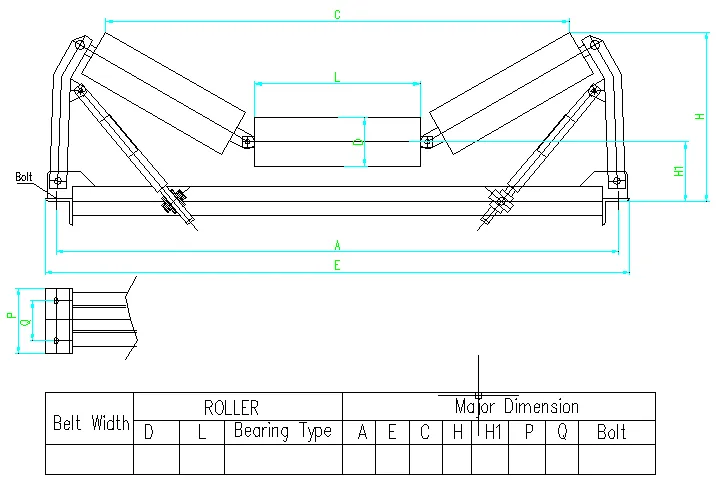

Technical Diagrams and Parameters

Figure 5: Technical diagram of Spring Impact Idler

The product's technical specifications include:

- Roller diameter range: 48-219mm

- Axle diameter range: 17-60mm

- Wall thickness range: 2.5-6mm

- Coating options: Black, red, green, blue, or custom

Conclusion

The Spring Impact Idler represents a significant advancement in conveyor belt technology, offering a combination of innovation, durability, and adaptability. Its patented design, coupled with the expertise of Yanshan Aohua Machinery Equipment Manufacture Limited Company, ensures that it meets the demanding requirements of modern industrial applications.

With its ability to adjust to varying material impacts and provide optimal belt protection, this idler system is an essential component for any conveyor system looking to enhance efficiency and reduce maintenance costs. The product's compliance with international standards and its customizable features make it a versatile solution for a wide range of industries.

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025