Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Understanding the Functionality and Applications of Snub Rollers in Mechanical Systems

Understanding the Snub Roller A Key Component in Conveyor Systems

In the realm of industrial machinery and material handling, conveyor systems play an indispensable role in ensuring the efficient movement of goods. Among the vital components of these systems is the snub roller, a pivotal element that enhances the performance and reliability of conveyor belts. This article delves into the features, functions, and significance of the snub roller in modern industrial applications.

What is a Snub Roller?

A snub roller is a cylindrical component used in conveyor systems to redirect the path of a conveyor belt. Typically positioned at a specific angle to a drive pulley, the snub roller serves to increase the contact area between the belt and the pulley. This, in turn, enhances the frictional grip necessary for the effective transfer of power from the drive mechanism to the conveyor belt.

Functions of the Snub Roller

The primary function of the snub roller is to transfer energy efficiently between the motor-driven pulley and the conveyor belt. By increasing the belt's contact surface with the drive pulley, the snub roller allows for better traction, which is critical in scenarios where heavy loads must be moved. Additionally, it acts as a tensioning device, helping to maintain the proper tension in the conveyor belt, which is crucial for optimal performance and longevity.

Another vital role that snub rollers play is in the alignment and stabilization of the conveyor belt. They help to guide the belt in a controlled manner, preventing any sagging or misalignment that could lead to increased wear and costly downtime. By ensuring the belt remains taut and correctly oriented, snub rollers contribute to the overall reliability of the conveyor system.

Types of Snub Rollers

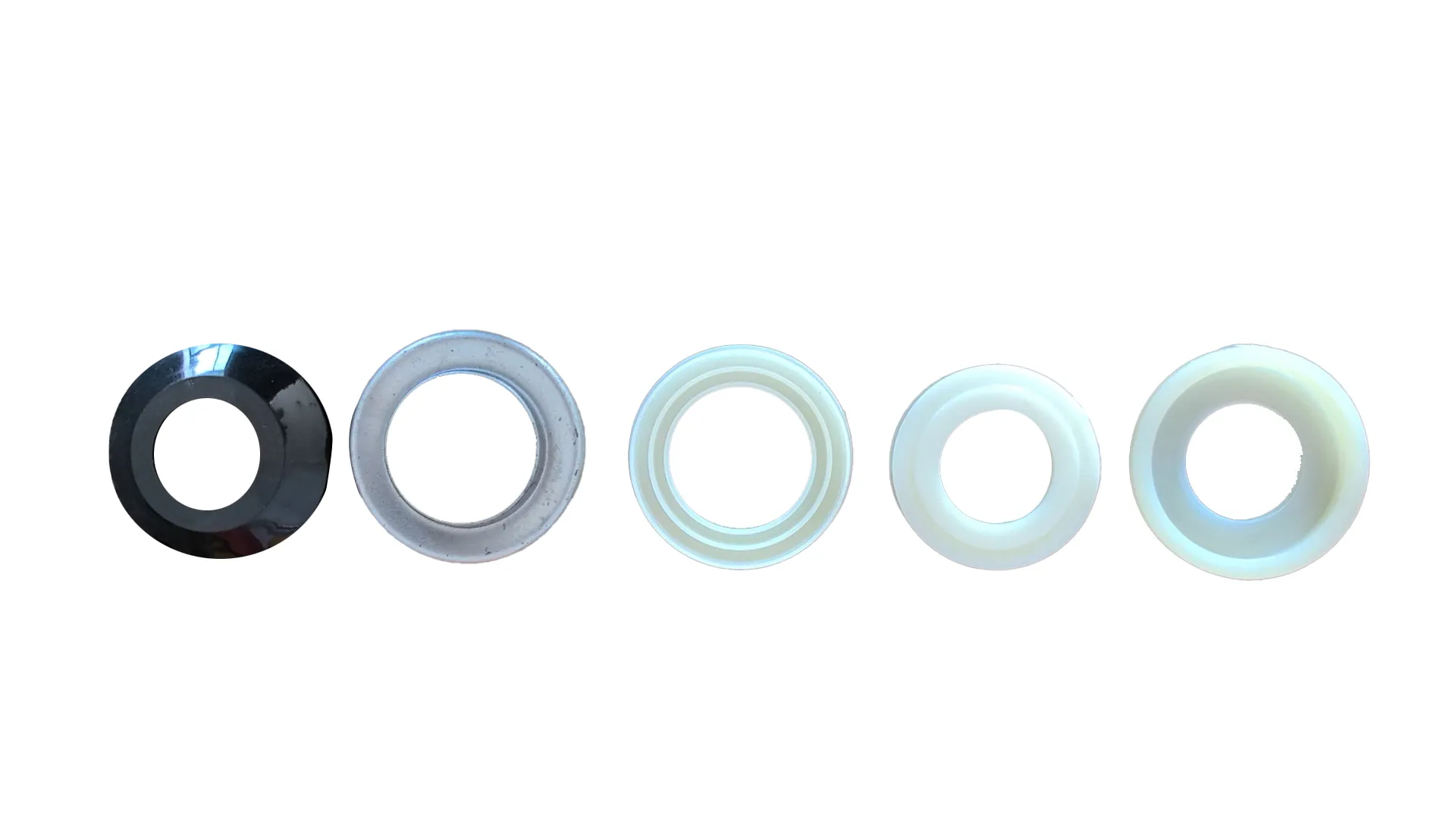

Snub rollers come in various designs and materials to suit different applications. The most common types include

snub roller

1. Standard Snub Rollers These are typically made from steel or other durable materials and are used in a wide range of conveyor systems.

2. Adjustable Snub Rollers These rollers can be adjusted to change the angle and tension, offering flexibility for different operational requirements.

3. Crowned Rollers Featuring a slight curvature, crowned rollers help keep the belt centered, reducing the likelihood of misalignment.

4. Rubber-Covered Rollers These provide additional grip and can help absorb vibrations, making them suitable for sensitive cargo.

Significance in Industrial Applications

The snub roller is especially significant in industries where heavy materials are transported, such as mining, construction, and manufacturing. In these sectors, the efficiency of a conveyor system can directly impact productivity and cost-effectiveness. By incorporating snub rollers into conveyor designs, companies can reduce energy costs, minimize maintenance, and extend the lifespan of their equipment.

Moreover, in an era increasingly focused on sustainability and efficiency, optimizing conveyor systems to reduce energy consumption is vital. Snub rollers facilitate this by ensuring that conveyors operate at peak efficiency, thereby lowering the carbon footprint associated with material handling.

Conclusion

In conclusion, the snub roller is a crucial component in the engineering of conveyor systems, playing an essential role in energy transfer, tension management, and belt alignment. As industries continue to evolve and seek greater efficiency in their operations, the importance of such components cannot be understated. By ensuring that snub rollers are properly maintained and integrated into conveyor systems, businesses can achieve improved performance and reliability, ultimately contributing to their success in an increasingly competitive market.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025