Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 12, 2025 11:26

Back to list

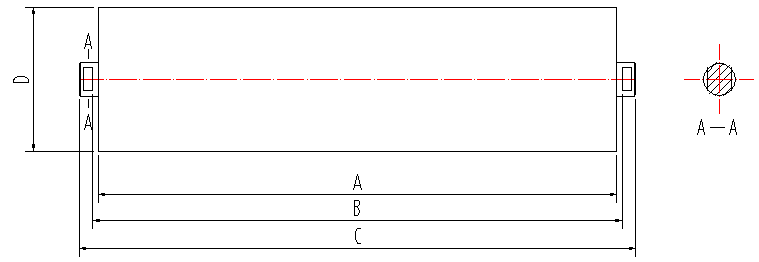

snub roller

The snub roller, a relatively less explored but highly innovative component in the mechanical and industrial domains, offers remarkable advantages that are often overlooked. Its unique design and versatility have bolstered various industries, enhancing the operational efficiency of countless machines. This piece delves into the core facets of snub rollers, offering readers an expert-driven overview that underscores their benefits and applications.

The authoritative nature of snub rollers comes from their construction—typically composed of robust materials. These materials, often steel or high-grade polyurethanes, are selected for their excellent wear resistance and ability to withstand pressures and impacts over extended periods. This reliability underpins the trust that industries have in snub rollers, making them a staple in environments where operational trustworthiness is imperative. Furthermore, the unique design of snub rollers allows them to be customized according to specific requirements. This adaptability ensures that they can cater to the needs of diverse industries and applications seamlessly. Custom engineering solutions might include altering the diameter, length, or material properties to suit particular needs, demonstrating the versatility and specialist capabilities attributed to snub rollers. In terms of safety, snub rollers enhance operational safety by preventing belt misalignment, which could otherwise lead to spillage or accidents within the conveyor system. Given the critical nature of maintaining safe working environments, the implementation of snub rollers becomes a strategic decision aimed at fostering secure and efficient workplaces. Conclusively, snub rollers stand out as an embodiment of experience and engineering excellence. Their ongoing development and adaptation to modern industrial needs keep them at the forefront of mechanical components. They offer unmatched reliability and performance, a testament to their indispensable role in enhancing the efficiency and safety of conveyor systems. As industries continue to evolve, snub rollers will undoubtedly remain a fundamental component, trusted by engineers and effectiveness-driven sectors worldwide.

The authoritative nature of snub rollers comes from their construction—typically composed of robust materials. These materials, often steel or high-grade polyurethanes, are selected for their excellent wear resistance and ability to withstand pressures and impacts over extended periods. This reliability underpins the trust that industries have in snub rollers, making them a staple in environments where operational trustworthiness is imperative. Furthermore, the unique design of snub rollers allows them to be customized according to specific requirements. This adaptability ensures that they can cater to the needs of diverse industries and applications seamlessly. Custom engineering solutions might include altering the diameter, length, or material properties to suit particular needs, demonstrating the versatility and specialist capabilities attributed to snub rollers. In terms of safety, snub rollers enhance operational safety by preventing belt misalignment, which could otherwise lead to spillage or accidents within the conveyor system. Given the critical nature of maintaining safe working environments, the implementation of snub rollers becomes a strategic decision aimed at fostering secure and efficient workplaces. Conclusively, snub rollers stand out as an embodiment of experience and engineering excellence. Their ongoing development and adaptation to modern industrial needs keep them at the forefront of mechanical components. They offer unmatched reliability and performance, a testament to their indispensable role in enhancing the efficiency and safety of conveyor systems. As industries continue to evolve, snub rollers will undoubtedly remain a fundamental component, trusted by engineers and effectiveness-driven sectors worldwide.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS