Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Exploring the Benefits and Applications of Snub Rollers in Various Industries

Understanding Snub Rollers Applications, Benefits, and Maintenance

Snub rollers are an essential component in conveyor systems, often employed in various industries to enhance material handling efficiency. These mechanical devices are designed to provide a controlled deviation of belts and are pivotal in maintaining optimal tension and tracking. In this article, we will delve into the features, applications, benefits, and maintenance of snub rollers.

What is a Snub Roller?

A snub roller, also known as a snub pulley, is primarily used to redirect the conveyor belt, helping to guide it along its path. By providing a point of contact that deviates from the primary head and tail pulleys, snub rollers can effectively increase the tension of the belt. This increased tension allows the belt to grip more firmly onto the pulleys, thus facilitating a more efficient transportation of materials.

Applications of Snub Rollers

Snub rollers find use across various industries, particularly in mining, agriculture, manufacturing, and logistics. In mining operations, for instance, they manage the heavy loads on conveyor belts that transport ores and minerals. In agricultural settings, they assist in the movement of grains and other bulk products. Manufacturing companies utilize snub rollers to streamline assembly lines, while logistics operations benefit from their ability to keep conveyor systems running smoothly within warehouses and distribution centers.

Benefits of Snub Rollers

1. Enhanced Belt Control One of the primary advantages of using snub rollers is their ability to enhance belt control. By providing an additional contact point, they help maintain proper alignment, reducing the likelihood of belt misalignment or slippage.

2. Increased Tension The introduction of snub rollers allows for better tension management. Proper tension is critical for maintaining belt efficiency and prolonging the lifespan of both the belt and the conveyor system.

3. Reduced Wear and Tear By ensuring that the belt runs smoothly and remains properly aligned, snub rollers help minimize wear and tear. This reduction in friction and material degradation leads to less frequent replacements and lower maintenance costs.

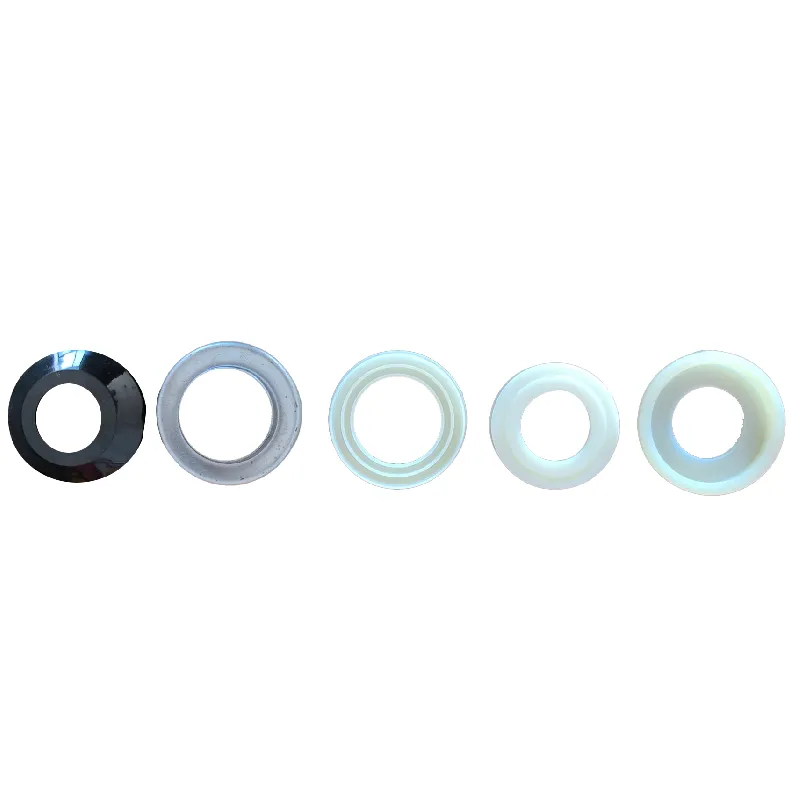

snub roller

4. Versatility Snub rollers can be adjusted to suit various operational needs. This flexibility allows them to be used across different types of conveyor systems and in handling a wide range of materials.

5. Safety By improving the operational stability of conveyor systems, snub rollers contribute to safer work environments. A well-maintained conveyor system reduces the risk of accidents caused by belt failure or misalignment.

Maintenance of Snub Rollers

To maintain the efficiency and longevity of snub rollers, regular maintenance must be practiced. Here are some tips

1. Regular Inspections Conduct frequent inspections to assess the condition of the snub roller and surrounding components. Look for signs of wear, damage, or misalignment.

2. Lubrication Keep the bearings of the snub roller properly lubricated to prevent friction-related wear and to ensure smooth operation. Check the manufacturer's guidelines for recommended lubrication intervals.

3. Alignment checks Periodically verify the alignment of the snub rollers and the connected belts. Misalignment can lead to increased wear and could compromise the effectiveness of the conveyor system.

4. Replace Worn Components Be proactive in replacing any worn or damaged parts, including the snub rollers themselves, before they lead to larger operational issues.

5. Training Staff Ensuring that personnel responsible for operating and maintaining conveyor systems understand the role and importance of snub rollers can aid in maximizing their efficiency.

In conclusion, snub rollers are integral to the effective operation of conveyor systems across various industries. By providing enhanced belt control, increasing tension, and minimizing wear, they contribute significantly to the efficient and safe movement of materials. With proper maintenance, snub rollers can offer long-lasting performance, ensuring smooth operations and reducing overall costs. Understanding their function and implementing best practices will allow businesses to harness the full potential of their conveyor systems.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025