Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu snub pulley is located at

Understanding the Snub Pulley and Its Location

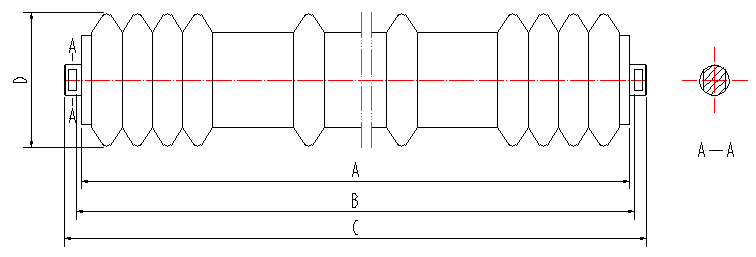

In the world of mechanical engineering and material handling systems, pulleys play a critical role in facilitating the movement of loads efficiently. One particular type of pulley, the snub pulley, serves an essential function in managing belt tension and guiding the direction of motion within a system. Understanding the technical aspects of the snub pulley and its optimal location can greatly enhance the performance and longevity of conveyor systems.

What is a Snub Pulley?

A snub pulley is a type of idler pulley that is used to increase the angle of wrap around a driving pulley or to guide the belt in a conveyor system. It is not driven by a motor but assists in the tensioning of the conveyor belt. By increasing the contact area between the belt and the driven pulley, the snub pulley helps improve the transmission of power and the overall efficiency of the system. This increased contact surface is crucial for applications requiring a higher level of control and traction.

Functions of a Snub Pulley

The primary function of a snub pulley is to change the direction of the conveyor belt. This is particularly important in systems where the conveyor needs to navigate around corners or bends. In addition to directional changes, snub pulleys also serve the following functions

1. Tension Adjustment They help maintain proper tension in the belt, which is crucial for preventing slippage and ensuring smooth operation. 2. Alignment Maintenance By guiding the belt, snub pulleys help prevent misalignment which can lead to excessive wear and tear on the belt and other components. 3. Load Distribution Snub pulleys contribute to even load distribution across the belt, reducing the risk of belt failures and enhancing system reliability.

snub pulley is located at

Optimal Location of the Snub Pulley

The placement of a snub pulley in a conveyor system is vital for its effectiveness. Typically, the snub pulley should be located in areas that maximize its ability to guide the belt and maintain tension. Here are some key considerations for the optimal location

1. Near the Drive Pulley Placing the snub pulley close to the drive pulley can enhance the wrap angle, providing better grip and reducing slippage. This is particularly beneficial in high-torque applications. 2. In Curved Sections If the conveyor path includes curves or bends, snub pulleys should be strategically placed to maintain belt alignment and prevent skewing. They can help keep the belt on track, especially in tight-radius turns.

3. Before or After Load Points Positioning snub pulleys before or after load transfer points can help accommodate changes in tension that occur when heavy loads are placed on the belt. This placement ensures consistent tension is maintained, reducing the risk of slippage during operation.

4. Consideration of Environmental Factors The surrounding environment, such as exposure to dust, moisture, and temperature extremes, can affect the performance of the snub pulley. Locating the pulley in a protected area can help prolong its lifespan.

Conclusion

In conclusion, the snub pulley is a vital component of many conveyor systems, enhancing direction, tension, and performance overall. Its strategic placement is critical to ensuring that systems run smoothly, efficiently, and reliably. Engineers and technicians must consider various factors when determining the best location for snub pulleys, including proximity to drive components, the layout of the conveyor path, and environmental influences. By understanding the role and optimal positioning of snub pulleys, professionals can design and maintain systems that promote productivity and minimize operational disruptions.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025