Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 12, 2025 09:43

Back to list

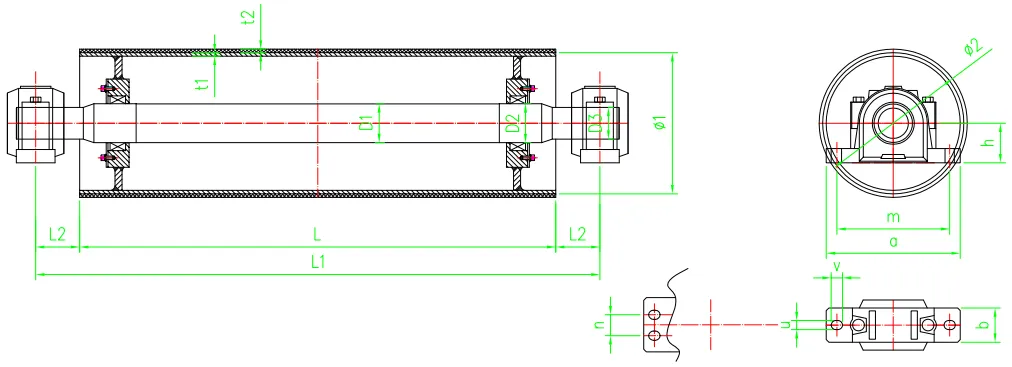

snub roller

The role of a snub pulley in a belt conveyor system is often underestimated, yet it is a critical component that optimizes the conveyor's performance. For those invested in industries reliant on efficient material handling—such as mining, manufacturing, and distribution—understanding the nuances of snub pulleys can enhance operational efficiency, safety, and system longevity.

Further emphasizing the snub pulley’s significance is its role in energy efficiency. By improving belt traction, the system’s motors do not need to exert as much force, thereby reducing energy consumption. Over time, this improved efficiency translates to significant cost savings and reduces the facility's carbon footprint, making it a sustainable choice amid growing environmental concerns. In terms of maintenance, well-designed snub pulleys contribute to the overall health of the conveyor system. They reduce wear and tear on the belt, minimizing the frequency of belt replacements and repairs. Regular inspection and maintenance schedules should include checking the snub pulley for alignment, surface wear, and structural integrity. Expert technicians use advanced diagnostic tools to monitor the pulley's condition, ensuring any issues are preemptively addressed. In conclusion, the integration of a snub pulley is not merely a technical necessity but a strategic choice for enhancing conveyor performance. Their contribution to increased friction, enhanced energy efficiency, and reduced maintenance demands cannot be overstated. As industries advance, investing in robust snub pulley designs will be a hallmark of cutting-edge operational efficiency. For professionals committed to optimizing their conveyor systems, the expertise in snub pulley application stands as a testament to a commitment to excellence and innovation in material handling solutions.

Further emphasizing the snub pulley’s significance is its role in energy efficiency. By improving belt traction, the system’s motors do not need to exert as much force, thereby reducing energy consumption. Over time, this improved efficiency translates to significant cost savings and reduces the facility's carbon footprint, making it a sustainable choice amid growing environmental concerns. In terms of maintenance, well-designed snub pulleys contribute to the overall health of the conveyor system. They reduce wear and tear on the belt, minimizing the frequency of belt replacements and repairs. Regular inspection and maintenance schedules should include checking the snub pulley for alignment, surface wear, and structural integrity. Expert technicians use advanced diagnostic tools to monitor the pulley's condition, ensuring any issues are preemptively addressed. In conclusion, the integration of a snub pulley is not merely a technical necessity but a strategic choice for enhancing conveyor performance. Their contribution to increased friction, enhanced energy efficiency, and reduced maintenance demands cannot be overstated. As industries advance, investing in robust snub pulley designs will be a hallmark of cutting-edge operational efficiency. For professionals committed to optimizing their conveyor systems, the expertise in snub pulley application stands as a testament to a commitment to excellence and innovation in material handling solutions.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS