Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Advantages of Using Snub Pulleys in Belt Conveyor Systems for Enhanced Performance

Understanding Snub Pulleys for Belt Conveyors

Belt conveyors are essential components in various industries, serving as reliable systems for transporting materials over distances. Among the many components of a belt conveyor system, the snub pulley plays a pivotal role that often goes unnoticed. Understanding the function and significance of a snub pulley can enhance the efficiency and reliability of belt conveyor operations.

What is a Snub Pulley?

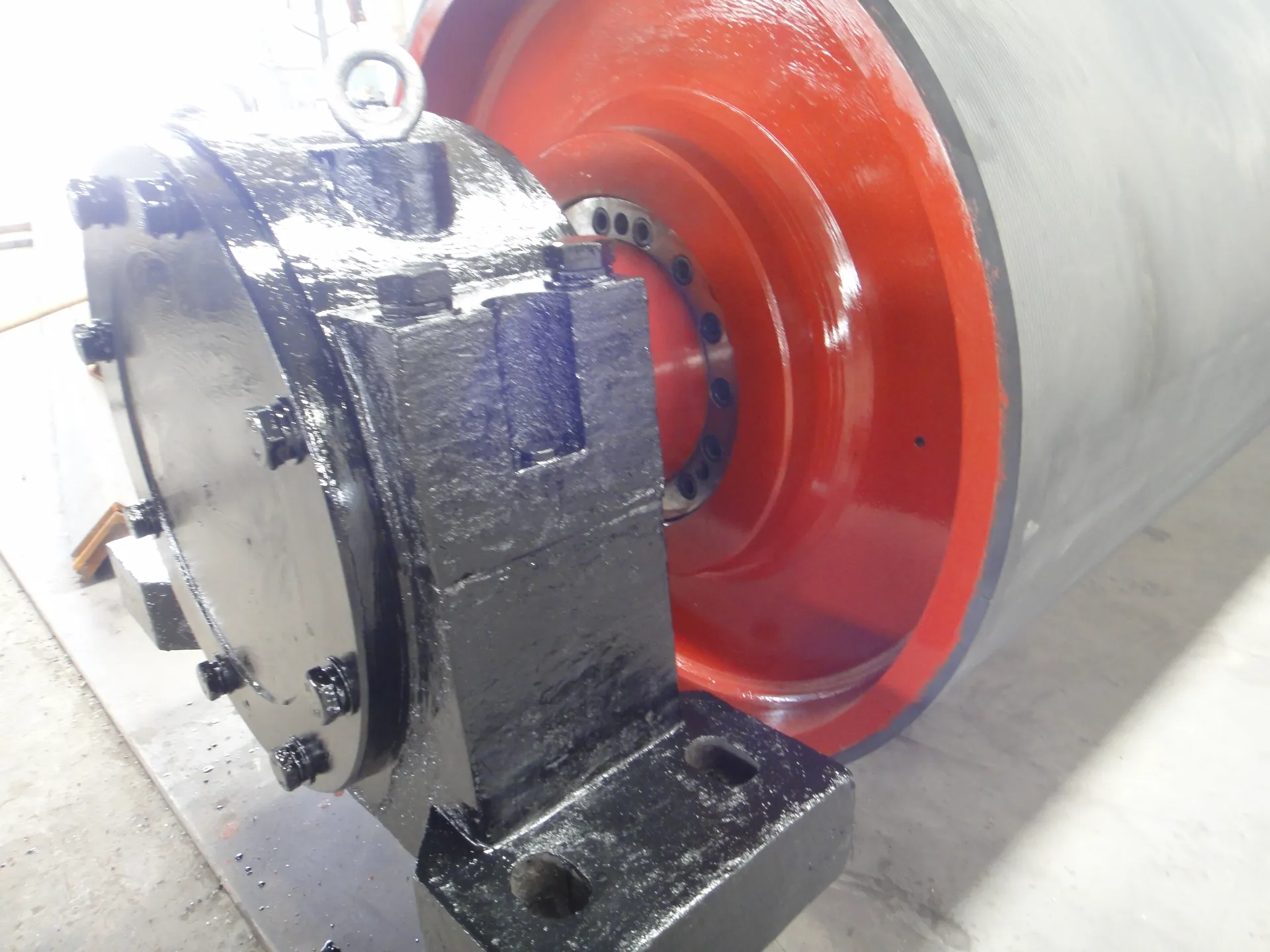

A snub pulley is a type of pulley used in belt conveyor systems, characterized by its position to change the direction of the belt and provide additional tension. Typically, it is situated near the drive pulley and is often smaller than the other pulleys within the system. The primary purpose of a snub pulley is to create a tighter wrap around the drive pulley, which improves the grip of the conveyor belt and enhances its operational efficiency.

Significance of Snub Pulleys

1. Belt Tension Control One of the critical roles of a snub pulley is to help maintain the necessary tension in the conveyor belt. Proper tension is crucial for avoiding slippage and ensuring the belt runs smoothly. Inadequate tension can lead to inefficiencies, while excessive tension can increase wear on the belt and other components.

2. Improving Drive Efficiency By wrapping the belt more tightly around the drive pulley, the snub pulley increases the frictional force between the belt and the drive pulley. This boost in friction results in improved drive efficiency, reducing the amount of power needed to move materials on the conveyor.

3. Minimizing Belt Wear The design and placement of the snub pulley can significantly minimize the wear and tear on the conveyor belt. By ensuring that the belt maintains an appropriate degree of tension and alignment, the snub pulley helps extend the lifespan of the belt, which can be a significant cost-saving factor for operations.

4. Facilitating Belt Tracking A properly positioned snub pulley can assist in keeping the belt centered and properly aligned on the conveyor. This function is essential for preventing potential operational issues that can arise from belt misalignment, such as damage to the belt edges or other components.

snub pulley for belt conveyor

5. Environmental Resistance Many industries operate in challenging environments subject to dust, dirt, moisture, and chemicals. Snub pulleys can be designed with materials that resist corrosion and wear, thereby extending their lifespan and maintaining the overall efficiency of the belt conveyor system.

Installation and Maintenance Considerations

The installation and maintenance of snub pulleys are crucial for optimal performance. Here are some key considerations

- Correct Positioning The exact placement of the snub pulley is vital; it should be positioned to ensure the correct tension of the belt while also facilitating easy access for maintenance. Engineers must consider the conveyor layout, load requirements, and potential wear points when determining the optimal position.

- Regular Inspections Routine inspections are essential for identifying signs of wear, misalignment, or other potential issues with the snub pulley. This proactive approach can prevent costly breakdowns and extend the overall lifespan of the conveyor system.

- Lubrication Depending on the design and materials, some snub pulleys may require regular lubrication to ensure smooth operation. This reduces friction and helps prevent overheating, which can lead to premature wear or failure.

- Material Selection The materials used for snub pulleys should be suitable for the specific operational environment, considering factors such as load capacity, temperature fluctuations, and exposure to chemicals. Selecting the right materials can significantly influence the lifespan of both the snub pulley and the belt.

Conclusion

In summary, while often overlooked, snub pulleys are essential components of belt conveyor systems that contribute significantly to efficiency, reliability, and longevity. Their roles in controlling belt tension, improving drive efficiency, minimizing wear, and facilitating proper tracking cannot be overstated. Proper installation, maintenance, and material selection are crucial for maximizing the performance of snub pulleys. By understanding the importance of these components, operations managers and engineers can take the necessary steps to ensure a more efficient and reliable belt conveyor system, ultimately leading to improved productivity and reduced operational costs.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025