Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 12, 2025 02:57

Back to list

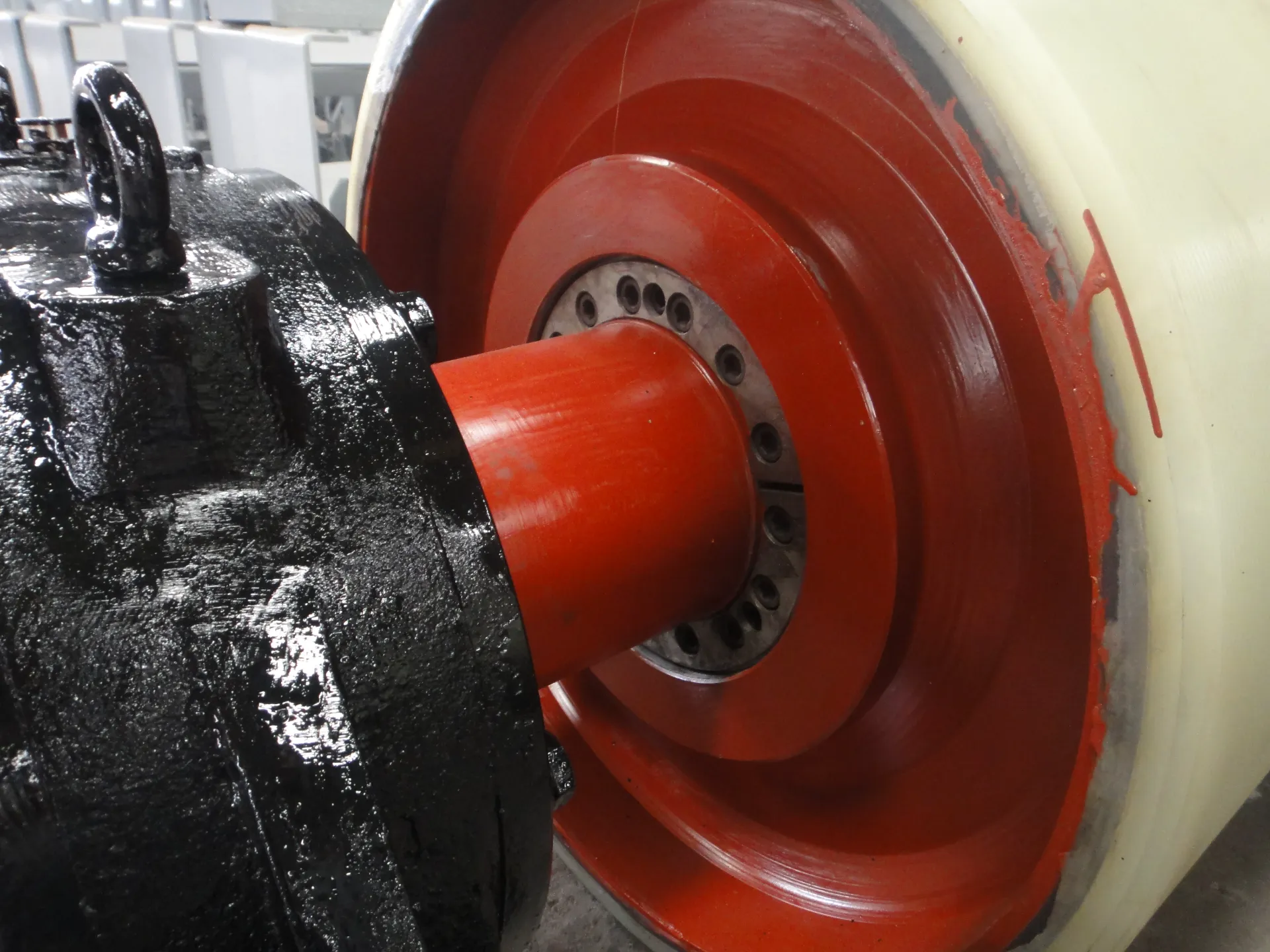

snub roller

In the realm of conveyor systems, the snub pulley often remains one of the most misunderstood components, yet it is undeniably critical for the efficient operation of belt-driven transport mechanisms. Through real-world experience, industry expertise, authoritative insights, and trustworthiness, let's delve into the significance of the snub pulley and its impact on conveyor system performance.

Moreover, from a reliability perspective, ensuring the regular maintenance and proper installation of snub pulleys fosters trustworthiness in conveyor system operations. Industry professionals often emphasize the importance of periodic inspections to detect signs of wear or misalignment early. Trusted manufacturers offer warranties and customer service support to uphold the credibility of their products, reinforcing the importance of investing in reputable brands known for their quality and durability. By prioritizing the efficiency of the snub pulley, industries not only enhance their operational productivity but also align with sustainable practices. A well-maintained snub pulley reduces unnecessary energy consumption, promoting eco-friendly operations in an age where environmental responsibility is paramount. In conclusion, the snub pulley, while often understated, holds a powerful role in the sphere of conveyor systems. Armed with professional expertise and a commitment to quality assurance, businesses can leverage the full potential of snub pulleys to streamline their material handling processes. This testament to industry wisdom underscores the importance of informed decision-making based on experiential knowledge, strengthening the authoritative voice of those who recognize the true value of snub pulleys in ensuring trustworthy and efficient conveyor performance.

Moreover, from a reliability perspective, ensuring the regular maintenance and proper installation of snub pulleys fosters trustworthiness in conveyor system operations. Industry professionals often emphasize the importance of periodic inspections to detect signs of wear or misalignment early. Trusted manufacturers offer warranties and customer service support to uphold the credibility of their products, reinforcing the importance of investing in reputable brands known for their quality and durability. By prioritizing the efficiency of the snub pulley, industries not only enhance their operational productivity but also align with sustainable practices. A well-maintained snub pulley reduces unnecessary energy consumption, promoting eco-friendly operations in an age where environmental responsibility is paramount. In conclusion, the snub pulley, while often understated, holds a powerful role in the sphere of conveyor systems. Armed with professional expertise and a commitment to quality assurance, businesses can leverage the full potential of snub pulleys to streamline their material handling processes. This testament to industry wisdom underscores the importance of informed decision-making based on experiential knowledge, strengthening the authoritative voice of those who recognize the true value of snub pulleys in ensuring trustworthy and efficient conveyor performance.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS