Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu snub pulley

Understanding the Snub Pulley Functionality and Applications

In the realm of mechanical engineering and transportation, the snub pulley plays a pivotal role in enhancing the efficiency and functionality of various systems. Typically used in conjunction with conveyor belts, elevators, and other mechanical systems, a snub pulley is a specialized type of pulley that is designed to redirect the path of a belt or cable. This article explores the fundamental aspects of snub pulleys, including their design, functionality, and applications across different industries.

Design and Functionality

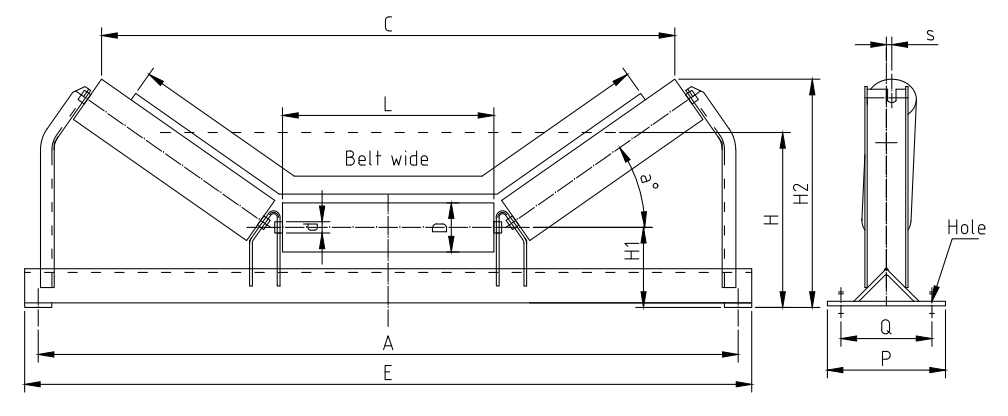

A snub pulley is usually mounted at an angle, deviating from the standard straight alignment of pulleys. This angled design allows the snub pulley to change the direction of a belt or cable without compromising its tension or operation. Snub pulleys provide greater friction against the belt, which increases the driving force and improves overall efficiency.

The construction of a snub pulley typically consists of a sturdy cylindrical structure that may be composed of metal or reinforced plastic materials. It is usually equipped with bearings that allow for smooth rotation. The positioning of the snub pulley is critical; it must be placed at a precise angle to maximize its effectiveness in changing the belt's path while maintaining tension.

Operational Mechanics

The primary function of a snub pulley is to increase the contact area between the belt and the driving pulley. By altering the belt's trajectory, it can create a tighter wrap around the drive pulley, which in turn enhances the friction and allows for better power transmission. The snub pulley also helps to maintain the correct belt alignment, reducing wear and tear over time.

In addition to improving power efficiency, snub pulleys are instrumental in controlling belt tension. Proper tension is crucial for preventing slippage, which can lead to premature wear and decreased operational efficiency. By using a snub pulley, engineers can better regulate the required tension, ensuring that the system operates smoothly and effectively.

Applications Across Industries

snub pulley

Snub pulleys find their applications in a wide variety of industries, including manufacturing, logistics, and mining. In manufacturing, they are often employed in conveyor systems to manage the flow of materials. The ability to change the direction of a conveyor belt allows for more efficient layout designs in factories, maximizing space and productivity.

In the logistics sector, snub pulleys are essential in automated sorting systems, where packages need to be redirected accurately. This capability improves workflow and speeds up processing times, which is critical in high-volume environments like distribution centers.

The mining industry also heavily relies on snub pulleys. Conveyor systems are vital for transporting mined materials from extraction sites to processing facilities. The rugged design and operational reliability of snub pulleys ensure that conveyors can handle the heavy loads and harsh conditions prevalent in mining operations.

Advantages of Snub Pulleys

The advantages of incorporating snub pulleys into mechanical systems are manifold. First and foremost, they enhance the efficiency of power transmission, allowing for smoother and more reliable operations. By improving the grip on the drive pulleys, these pulleys contribute to a significant reduction in energy costs, particularly in large-scale industrial operations.

Additionally, snub pulleys extend the lifespan of conveyor belts and other mechanical systems by reducing wear and tear. Improved tension management minimizes the risk of slippage and the associated damage, ensuring that components remain functional for longer periods.

Conclusion

In summary, snub pulleys are indispensable components in various mechanical and transportation systems. Their unique design allows them to enhance efficiency, maintain proper tension, and facilitate the seamless movement of materials across different industries. As technology continues to advance, the role of snub pulleys will likely evolve, catering to increasing demands for efficiency and sustainability in industrial operations. By understanding and leveraging the capabilities of snub pulleys, businesses can optimize their processes and achieve greater operational excellence.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025