Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 13, 2025 16:22

Back to list

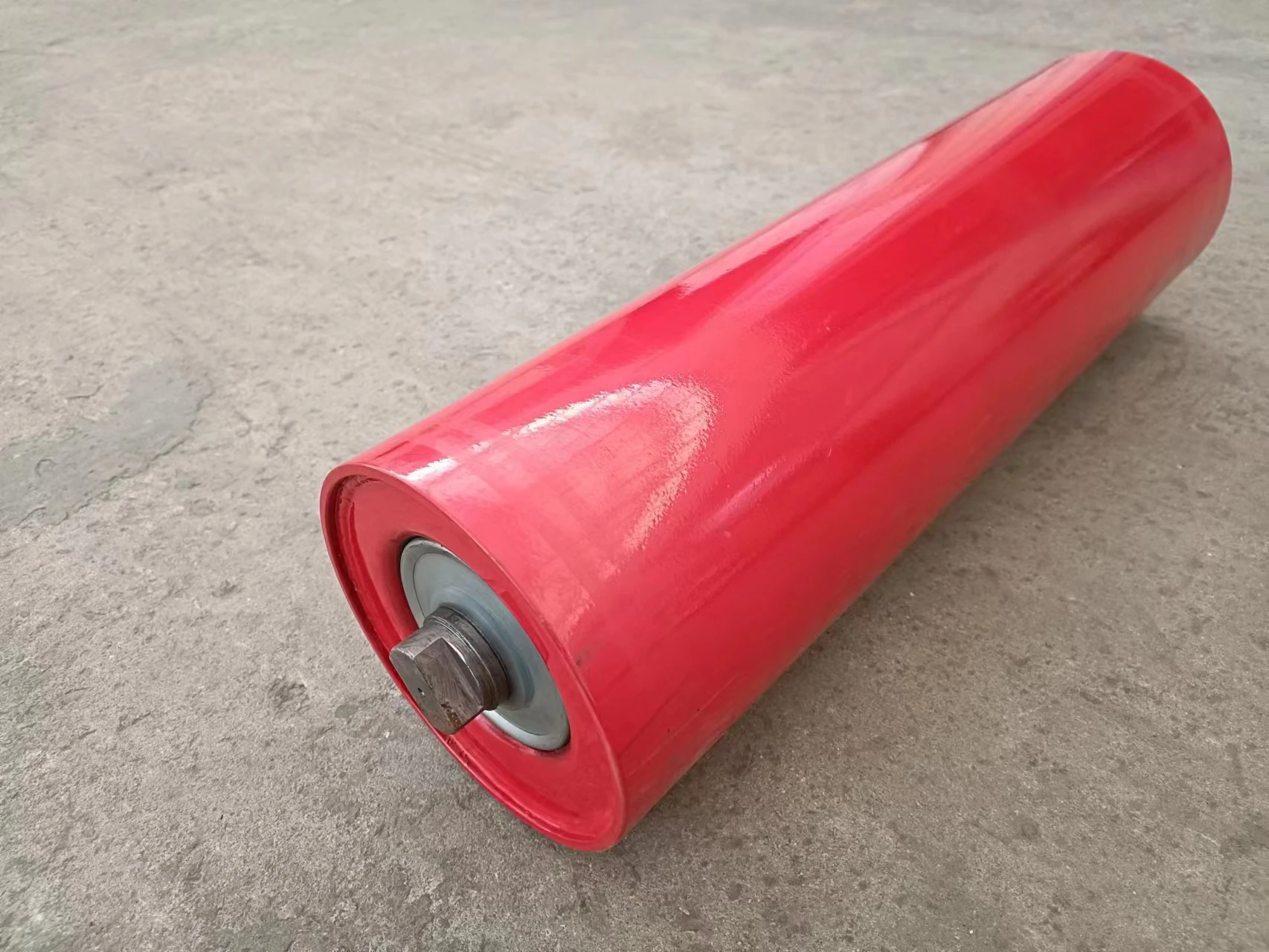

Side Roller (Also Called Standing Roller or Wing Roller)

Selecting the right components for a conveyor system is crucial in maintaining its efficiency and longevity. The flat return idler, though often overshadowed by more prominent machinery parts, plays a pivotal role in ensuring the smooth operation of conveyor belts, especially in industrial settings. By understanding its design, application, and benefits, businesses can harness the full potential of their conveyor systems while optimizing performance.

The authoritative stature of reputable flat return idler manufacturers is reinforced by rigorous quality testing processes. Each idler undergoes a series of checks, from load-bearing capacity to rotational speed, to ensure compliance with international quality standards such as ISO 9001. Manufacturers often collaborate with engineers and technical experts to innovate and improve the idler design, addressing industry-specific challenges and maintaining a competitive edge in the market. Trustworthiness is derived not just from high-quality products but also from comprehensive customer support services. Leading suppliers offer technical assistance and on-site inspection services to help clients select the most appropriate idlers for their conveyor systems. Furthermore, some manufacturers provide warranties that underscore their commitment to quality and customer satisfaction, providing peace of mind regarding the longevity and performance of the conveyor systems. The rising emphasis on sustainable and environmentally friendly operations is also evident in the materials and processes used in the production of flat return idlers. Manufacturers are increasingly adopting eco-friendly practices, using recycled materials where possible and ensuring that their production processes minimize environmental impact. This approach not only appeals to environmentally conscious organizations but also aligns with global sustainability goals. In conclusion, investing in high-quality flat return idlers is a strategic move for any business operating conveyors. These components, while seemingly minor, have a significant impact on operational efficiency, equipment lifespan, and overall cost-effectiveness. By selecting idlers from reputable manufacturers with proven expertise and authority, businesses not only bolster their operational reliability but also build a foundation of trust and quality assurance. As the industry continues to evolve, embracing innovative and sustainable solutions in conveyor components will undoubtedly drive enhanced performance and profitability for years to come.

The authoritative stature of reputable flat return idler manufacturers is reinforced by rigorous quality testing processes. Each idler undergoes a series of checks, from load-bearing capacity to rotational speed, to ensure compliance with international quality standards such as ISO 9001. Manufacturers often collaborate with engineers and technical experts to innovate and improve the idler design, addressing industry-specific challenges and maintaining a competitive edge in the market. Trustworthiness is derived not just from high-quality products but also from comprehensive customer support services. Leading suppliers offer technical assistance and on-site inspection services to help clients select the most appropriate idlers for their conveyor systems. Furthermore, some manufacturers provide warranties that underscore their commitment to quality and customer satisfaction, providing peace of mind regarding the longevity and performance of the conveyor systems. The rising emphasis on sustainable and environmentally friendly operations is also evident in the materials and processes used in the production of flat return idlers. Manufacturers are increasingly adopting eco-friendly practices, using recycled materials where possible and ensuring that their production processes minimize environmental impact. This approach not only appeals to environmentally conscious organizations but also aligns with global sustainability goals. In conclusion, investing in high-quality flat return idlers is a strategic move for any business operating conveyors. These components, while seemingly minor, have a significant impact on operational efficiency, equipment lifespan, and overall cost-effectiveness. By selecting idlers from reputable manufacturers with proven expertise and authority, businesses not only bolster their operational reliability but also build a foundation of trust and quality assurance. As the industry continues to evolve, embracing innovative and sustainable solutions in conveyor components will undoubtedly drive enhanced performance and profitability for years to come.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS