Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

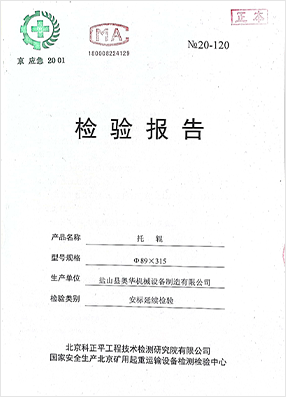

Zulu side roller

The Fascination of Side Rollers A Unique Perspective on Wind Transport Mechanisms

Side rollers, a critical innovation in the realm of material transportation, embody a fascinating blend of functionality and engineering. These devices have revolutionized how goods are moved in various industries, from manufacturing to logistics, providing an efficient alternative to traditional conveyor systems. This article delves into the workings, benefits, and applications of side rollers, highlighting their importance in contemporary mechanical transport solutions.

At the core of side roller technology is a simple yet ingenious design. Unlike standard conveyor belts that rely on a flat surface, side rollers utilize cylindrical rollers positioned horizontally along the edges. This structure allows materials to glide smoothly across the rollers, significantly reducing friction. The rotation of the rollers facilitates the movement of loads, making the transportation process not only faster but also less energy-consuming. This design optimally distributes weight, resulting in lower wear and tear on both the equipment and the transported materials.

One of the standout advantages of side rollers is their versatility. They can be implemented in various settings, including warehouses, assembly lines, and packaging facilities. Their adaptability allows them to handle a wide range of items, from small parts to larger containers. Furthermore, side rollers can be configured in numerous layouts—straight, curved, or elevated—making them suitable for complex transport systems. This flexibility means businesses can customize their operations to maximize efficiency, thereby improving productivity and reducing operational costs.

side roller

In terms of maintenance and sustainability, side rollers offer clear benefits as well. With fewer components compared to traditional conveyor systems, they are generally easier to maintain. The reduced friction and wear result in less frequent need for repairs, prolonging the lifespan of the equipment. Additionally, by optimizing energy use during transport, side rollers contribute to a reduced carbon footprint, making them an environmentally friendly choice for modern businesses. Their ability to streamline operations while promoting sustainability aligns with the increasing demand for eco-conscious practices in industry.

Moreover, the integration of technology into side roller systems has opened new avenues for advancement. With the implementation of automation and smart technologies, side rollers can now be incorporated into automated guided vehicles (AGVs) and other robotic systems. This synergy enhances operational efficiency and accuracy while allowing for real-time monitoring and data analysis. As businesses embrace Industry 4.0 principles, the evolution of side rollers will likely play a pivotal role in shaping the future of supply chain logistics.

In conclusion, side rollers represent a significant leap in material transport technology, blending simplicity and efficiency in one package. Their innovative design, versatility, and sustainability make them essential components of modern industrial workflows. As industries continue to evolve and adapt to new challenges, the role of side rollers will undoubtedly expand, paving the way for smarter and more efficient transportation solutions. From small-scale operations to large factories, the integration of side rollers can lead to transformative changes, underscoring their importance in the landscape of mechanical transport systems.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025