Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

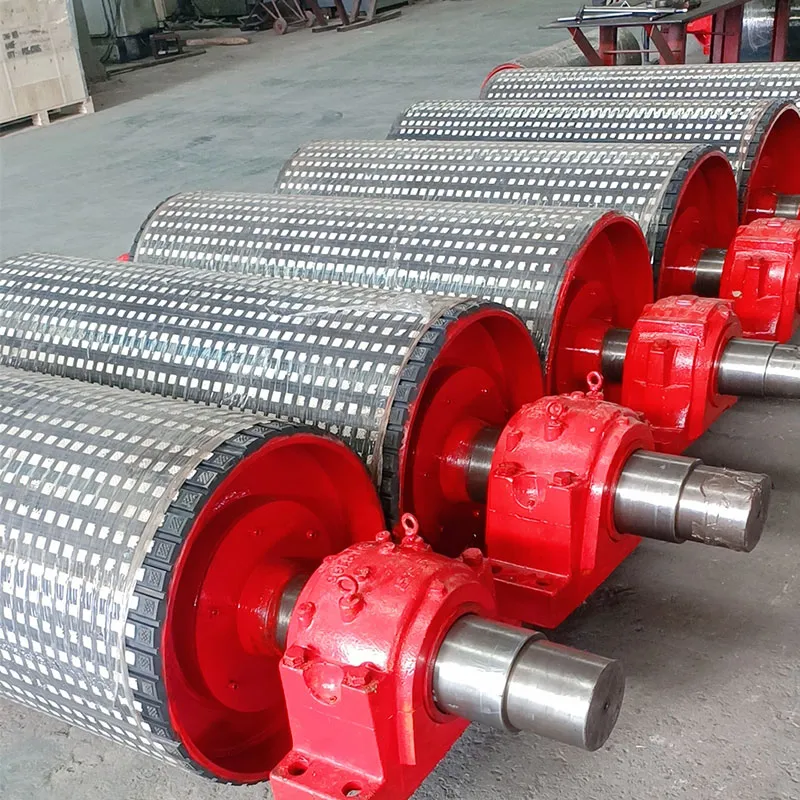

Zulu side mount rollers

Understanding Side Mount Rollers An Essential Component in Modern Conveyance Systems

In today's fast-paced industrial environment, the efficiency and efficacy of material handling systems cannot be overstated. One of the pivotal components contributing to this efficiency is the side mount roller. This article delves into the design, functionality, applications, and advantages of side mount rollers, emphasizing their importance in various sectors.

What are Side Mount Rollers?

Side mount rollers are specialized mechanical devices used to facilitate the movement of materials within conveyor systems. They are typically mounted along the side of a conveyor belt or rail, providing a stable and smooth surface for loads to glide on. Unlike traditional rollers that are positioned underneath the moving belt, side mount rollers allow for improved accessibility and ease of maintenance.

Design and Functionality

The typical side mount roller consists of a sturdy frame and a series of smoothly rotating cylindrical rollers. These rollers are engineered to handle heavy loads while minimizing friction, thereby reducing wear and tear on both the rollers and the conveyor system. The positioning of the rollers is crucial; they must be aligned perfectly to ensure efficient operation and to prevent any jams or operational mishaps.

Side mount rollers can be made from a variety of materials, including steel, plastic, and rubber, depending on the application and type of load being moved. Steel rollers are suitable for heavy-duty applications, while plastic options may be ideal for lighter, less abrasive materials. Additionally, the rollers can be fitted with different types of bearings to further enhance performance and longevity.

Applications of Side Mount Rollers

side mount rollers

Side mount rollers can be found across a wide range of industries. In manufacturing settings, they are commonly used in assembly lines, where they aid in the transportation of components from one station to another. In warehousing and distribution centers, these rollers help facilitate the movement of products through conveyor systems, thereby optimizing packing and shipping processes.

Moreover, the food and beverage industry utilizes side mount rollers for transporting packaged goods efficiently. Given the need for hygiene and sanitation, rollers in this sector are often made of food-grade materials and designed for easy cleaning. In retail, side mount rollers are essential in conveyor systems that manage the flow of products to checkouts, ensuring a swift and seamless customer experience.

Advantages of Side Mount Rollers

The benefits of using side mount rollers are numerous. First and foremost, they enhance operational efficiency. By reducing friction and facilitating smooth movement, they enable faster processing times, which is crucial in environments where time is of the essence. Their design also minimizes the risk of load damage, as the materials are securely cradled and guided throughout their journey.

Another significant advantage is the ease of maintenance. Side mount rollers are more accessible than traditional rollers, making inspections and replacements simpler and faster. This accessibility helps minimize downtime, allowing businesses to maintain productivity without the frequent interruptions that come with difficult-to-reach components.

Furthermore, the versatility of side mount rollers allows for customization in various applications. Businesses can work with manufacturers to design rollers that meet their specific needs, whether it be for size, load capacity, or material specifications. This adaptability makes them an ideal choice for a range of industries.

Conclusion

In summary, side mount rollers are an indispensable element of contemporary material handling systems. Their unique design, coupled with their ability to enhance efficiency, reduce maintenance, and facilitate smooth operations, makes them a preferred option in numerous applications. As industries continue to evolve and demand higher efficiency and reliability, the role of side mount rollers will undoubtedly grow, paving the way for more innovative solutions in the realm of logistics and material handling. As such, businesses investing in these technologies stand to benefit significantly from improved operational outcomes and a competitive edge in their respective markets.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025