Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

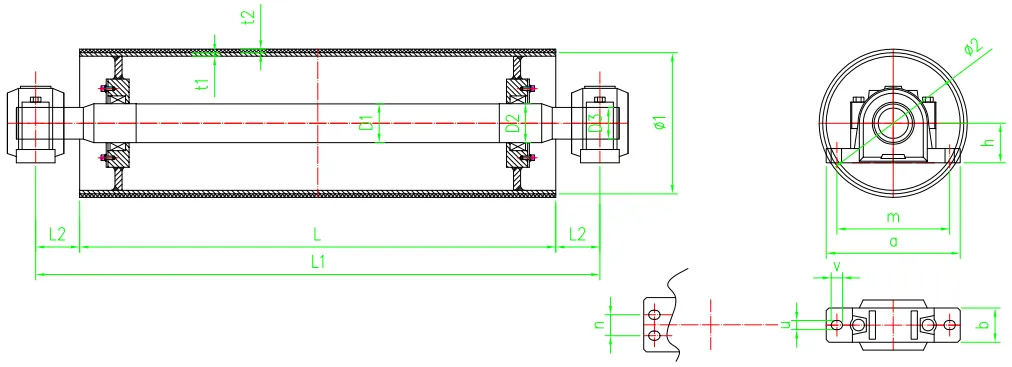

Zulu side mount rollers

Exploring the Benefits of Side Mount Rollers in Modern Manufacturing

In the ever-evolving landscape of manufacturing and production, efficiency and precision remain paramount. One of the key innovations that have emerged to enhance operational workflow is the side mount roller. These versatile components play a crucial role in various industries, including logistics, packaging, and assembly.

Side mount rollers are designed to facilitate the movement of materials and products along conveyor systems. Unlike traditional conveyors that often rely on overhead systems or flat surfaces, side mount rollers are positioned vertically, allowing items to glide smoothly across the conveyor's length. This design not only maximizes space but also optimizes the flow of goods, making it easier to navigate tight work environments.

One of the primary advantages of side mount rollers is their ability to handle heavy loads with minimal effort. Unlike conventional rollers that can become bogged down under weight, side mount rollers distribute the load evenly, reducing friction and wear. This feature is particularly beneficial in industries where heavy machinery and bulky materials are commonplace. By leveraging side mount rollers, companies can reduce downtime caused by equipment failures and ensure that production schedules remain on track.

side mount rollers

Moreover, side mount rollers contribute to enhanced safety within the workplace. When items can move smoothly and efficiently, the risk of accidents decreases significantly. For instance, when products are properly aligned and transported at a consistent speed, the likelihood of spills or collisions diminishes. This proactive approach to safety not only protects employees but also mitigates potential losses due to damaged goods.

From an environmental perspective, side mount rollers can also lead to significant energy savings. By optimizing the flow of materials, businesses can often reduce the energy required to operate their conveyor systems. Furthermore, the reduction in friction means that motors and equipment can work more efficiently, leading to lower overall energy consumption. This not only cuts costs but also aligns with the growing emphasis on sustainability in manufacturing practices.

In addition to these practical benefits, side mount rollers can be customized to meet specific operational needs. Depending on the application, manufacturers can adjust the size, material, and configuration of the rollers to suit various product types. This flexibility allows businesses to tailor their systems for maximum efficiency and productivity.

In conclusion, side mount rollers represent a significant advancement in the field of material handling. Their ability to enhance efficiency, improve safety, promote sustainability, and offer customization options makes them an invaluable asset in modern manufacturing environments. As industries continue to seek innovative solutions for their operational challenges, side mount rollers will undoubtedly play a pivotal role in shaping the future of production and logistics.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025