Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

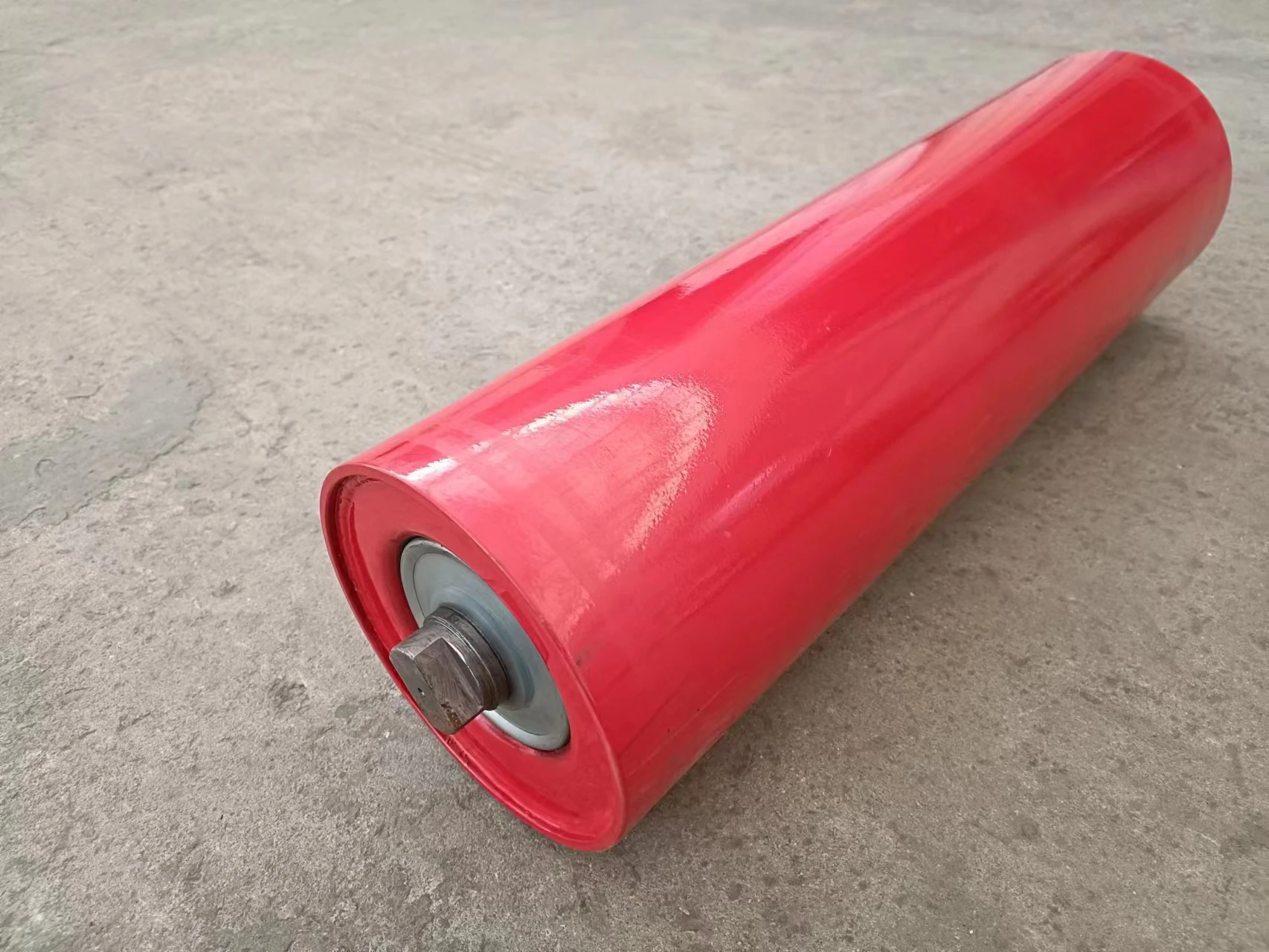

Zulu Innovative Self-Cleaning Tail Pulley Design for Improved Conveyor Efficiency and Maintenance

The Importance of Self-Cleaning Tail Pulleys in Conveyor Systems

In industrial settings, efficiency and reliability are paramount, especially when it comes to material handling systems like conveyor belts. A crucial component of these systems is the tail pulley, which is often subject to various operational challenges, including material buildup, contamination, and wear. To address these issues, self-cleaning tail pulleys have emerged as a vital innovation, aiding in the efficiency and longevity of conveyor systems.

Understanding Tail Pulleys

Tail pulleys are located at the discharge end of a conveyor system. Their primary function is to control the tension of the belt and assist in material transfer. However, they also face unique challenges due to the nature of their operation. As material moves along the conveyor belt, some can inadvertently accumulate on the tail pulley, leading to obstructions, increased wear, and potential conveyor system failures.

The Challenges of Material Buildup

Material buildup on the tail pulley can impede the conveyor’s smooth operation. Over time, accumulated material can cause misalignment, resulting in decreased efficiency and higher operational costs. Furthermore, the additional weight from the buildup can lead to premature wear and tear on components, necessitating frequent maintenance and replacement. In worst-case scenarios, excessive buildup may even pose safety hazards, increasing the risk of accidents in the workplace.

The Self-Cleaning Mechanism

To counteract these challenges, self-cleaning tail pulleys have been designed with specific features that promote the automatic removal of material buildup. These pulleys often incorporate angled surfaces, grooves, or innovative designs that facilitate the natural process of material shedding as the conveyor operates. The self-cleaning action allows the pulley to remain free of obstruction, ensuring that the belt operates smoothly and efficiently.

One common design for self-cleaning tail pulleys involves the integration of a spiral or helical element that encourages the movement of material away from the pulley. As the conveyor belt moves, the spiral action effectively dislodges any accumulated material, allowing it to fall away and preventing blockages. This not only enhances the efficiency of the conveyor system but also reduces the need for manual cleaning efforts, saving time and labor costs.

Benefits of Self-Cleaning Tail Pulleys

self cleaning tail pulley

The implementation of self-cleaning tail pulleys brings numerous benefits to industrial operations

1. Reduced Downtime By minimizing material buildup, these pulleys help maintain optimal operational conditions, reducing the frequency of maintenance interventions and downtime.

2. Increased Efficiency With consistent performance and reduced friction, self-cleaning tail pulleys ensure that conveyor systems operate at peak efficiency, enhancing overall productivity.

3. Lower Maintenance Costs The innovative design of self-cleaning pulleys translates to less wear on the conveyor system, leading to lower maintenance and replacement costs over time.

4. Enhanced Safety Reducing the risk of material build-up not only protects the equipment but also minimizes potential safety hazards, ensuring a safer working environment for employees.

5. Environmental Benefits Efficient material handling with reduced spillage contributes to a lower environmental impact by minimizing waste and improving resource management.

Future Trends and Innovations

As industries continue to evolve, so do the technologies utilized in conveyor systems. The future of self-cleaning tail pulleys may include smart technologies that monitor performance and provide real-time data on material buildup and other operational parameters. Such advancements could lead to even greater efficiencies and predictive maintenance strategies, further optimizing the performance of conveyor systems.

In conclusion, self-cleaning tail pulleys represent a critical advancement in the design of conveyor systems. By addressing the challenges of material buildup and promoting seamless operations, they significantly contribute to improved efficiency, reduced maintenance costs, and enhanced safety. As industries strive for greater efficiency and sustainability, the adoption of self-cleaning components will likely become increasingly important, positioning them as an essential element in modern material handling solutions.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025