Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu self cleaning tail pulley

Self-Cleaning Tail Pulley Enhancing Conveyor Efficiency

In the industrial sector, conveyor systems play a pivotal role in streamlining processes, whether in manufacturing, mining, or material handling. Among the various components that makeup conveyor systems, the tail pulley is significant, often subjected to challenging conditions that can lead to inefficiencies. To combat this, self-cleaning tail pulleys have emerged as a vital innovation. This article explores the concept, advantages, and applications of self-cleaning tail pulleys, shedding light on their importance in maintaining operational efficiency.

Understanding the Tail Pulley

The tail pulley is located at the end of a conveyor system and serves multiple functions. It helps to maintain the tension of the conveyor belt, supports the return side of the belt, and facilitates the discharge of materials. Over time, tail pulleys can accumulate dust, debris, and material spillage, which may hinder their performance and lead to belt misalignment and increased wear. This accumulation can result in reduced efficiency, increased maintenance costs, and even unexpected downtime.

The Concept of Self-Cleaning Tail Pulleys

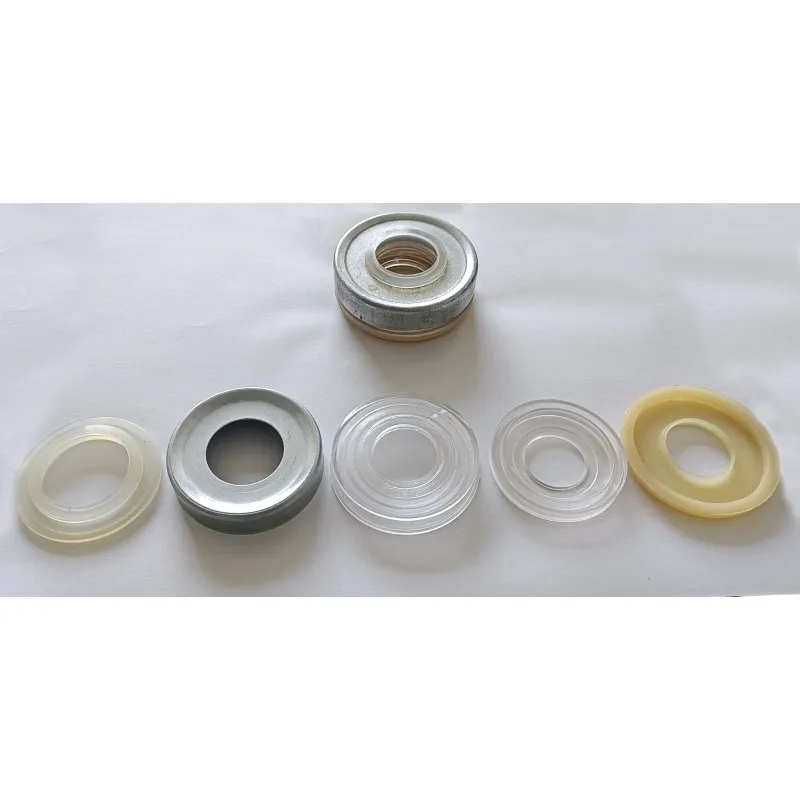

Self-cleaning tail pulleys are designed to mitigate the issues caused by material accumulation. They feature a specialized design that promotes the automatic removal of adhering materials as the conveyor operates. The self-cleaning mechanism often includes design features such as a spiral or dome shape, which facilitates the shedding of materials. Additionally, some models integrate rubber or other suitable materials to enhance cleaning action.

Advantages of Self-Cleaning Tail Pulleys

1. Reduced Maintenance One of the most significant advantages of self-cleaning tail pulleys is the reduced need for manual cleaning. Traditional tail pulleys often require regular maintenance to clear accumulated material, demanding labor and time. Self-cleaning designs significantly lessen this burden, allowing maintenance personnel to focus on other critical tasks.

self cleaning tail pulley

2. Enhanced Safety Dirty pulleys can pose safety hazards in the workplace, leading to slips, trips, and falls. By reducing debris accumulation, self-cleaning tail pulleys contribute to a safer working environment, minimizing the risk of accidents related to material buildup.

3. Increased Operational Efficiency Self-cleaning tail pulleys ensure that the conveyor system operates at peak efficiency. By preventing material build-up, these components help maintain consistent belt tension and alignment. Consequently, this leads to smoother operation and a faster throughput of materials.

4. Extended Equipment Life Regular maintenance reduces wear and tear on conveyor parts. By minimizing the accumulation of material on tail pulleys, the self-cleaning design helps extend the life of not only the tail pulley itself but also the entire conveyor system.

5. Cost-Effectiveness Although the initial investment in self-cleaning tail pulleys may be higher than traditional models, the long-term savings in maintenance, reduced downtime, and enhanced operational efficiency often outweigh the initial costs. This makes them a financially sound choice for industries reliant on conveyor systems.

Applications in Various Industries

Self-cleaning tail pulleys are versatile and can be utilized across various industries. In mining, for instance, they help manage the heavy loads and abrasive materials that can easily cling to conventional tail pulleys. In manufacturing environments, these pulleys cater to the fast-paced nature of production lines by ensuring minimal disruption. Additionally, in aggregate handling and recycling operations, self-cleaning tail pulleys facilitate the smooth transfer of materials without excessive spillage or accumulation.

Conclusion

Self-cleaning tail pulleys represent a significant advancement in conveyor technology, offering a host of benefits that enhance efficiency, safety, and overall operational effectiveness. As industries continue to evolve and demand higher performance from their equipment, innovations like the self-cleaning tail pulley will play a critical role in ensuring that conveyor systems meet these challenges efficiently. By investing in such technologies, businesses can achieve not only improved operational performance but also a sustainable approach to material handling. In the ever-competitive industrial landscape, embracing such innovations will be crucial for success.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025