Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

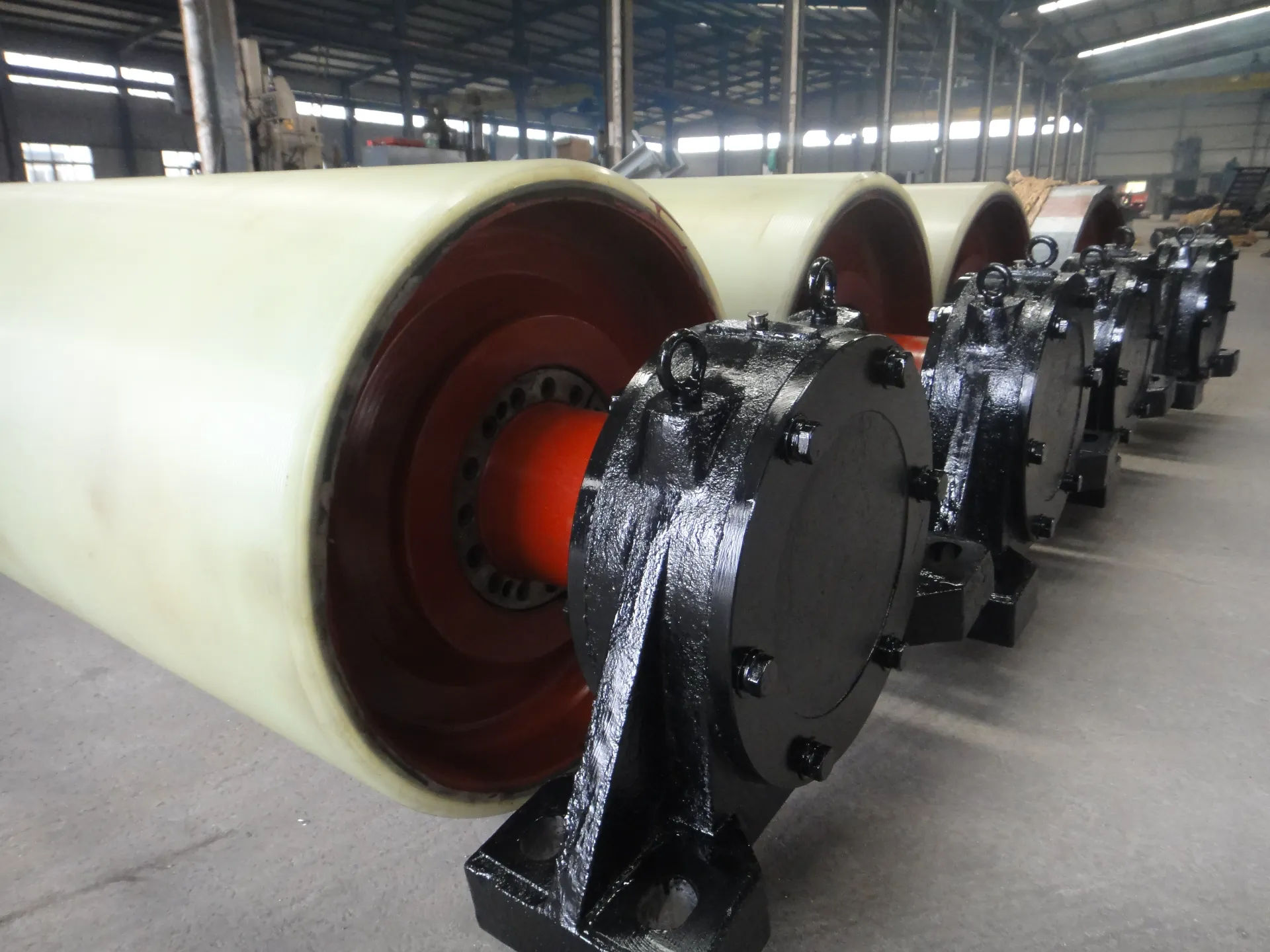

Zulu self cleaning tail pulley

Self-Cleaning Tail Pulley Enhancing Conveyor System Efficiency

Self-Cleaning Tail Pulley Enhancing Conveyor System Efficiency

A self-cleaning tail pulley is designed to remove material build-up that typically occurs during the transportation of goods. As the belt moves around the tail pulley, it often carries residual material that can cling and cause blockages or hinder the smooth operation of the conveyor. This is where the self-cleaning mechanism comes into play. Equipped with specially engineered designs, these pulleys utilize features such as raised surfaces or angled designs that allow for the material to be dislodged and fall away naturally, minimizing the need for manual cleaning.

self cleaning tail pulley

One of the most significant advantages of self-cleaning tail pulleys is the reduction of operational downtime. By preventing material accumulation and ensuring that the pulleys remain clean, companies can operate their conveyor systems more efficiently. This is particularly important in industries such as mining, agriculture, and manufacturing, where continuous operation is key to productivity. Moreover, the implementation of these pulleys can lead to lower maintenance costs, as there is less wear and tear on the conveyor components.

Environmental impact is another important consideration. Self-cleaning tail pulleys help to minimize spillage and waste, which is particularly crucial in processes that handle hazardous materials. By decreasing the likelihood of leaks and waste on the factory floor, these pulleys contribute to a safer working environment.

In conclusion, the self-cleaning tail pulley is a significant innovation in conveyor technology. Its ability to enhance operational efficiency, reduce maintenance needs, and promote a safer workplace makes it an essential feature in various industrial applications. As industries continue to seek ways to improve productivity and sustainability, the adoption of self-cleaning mechanisms in conveyor systems is likely to expand, showcasing the importance of engineering advancements in everyday operations.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025