Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

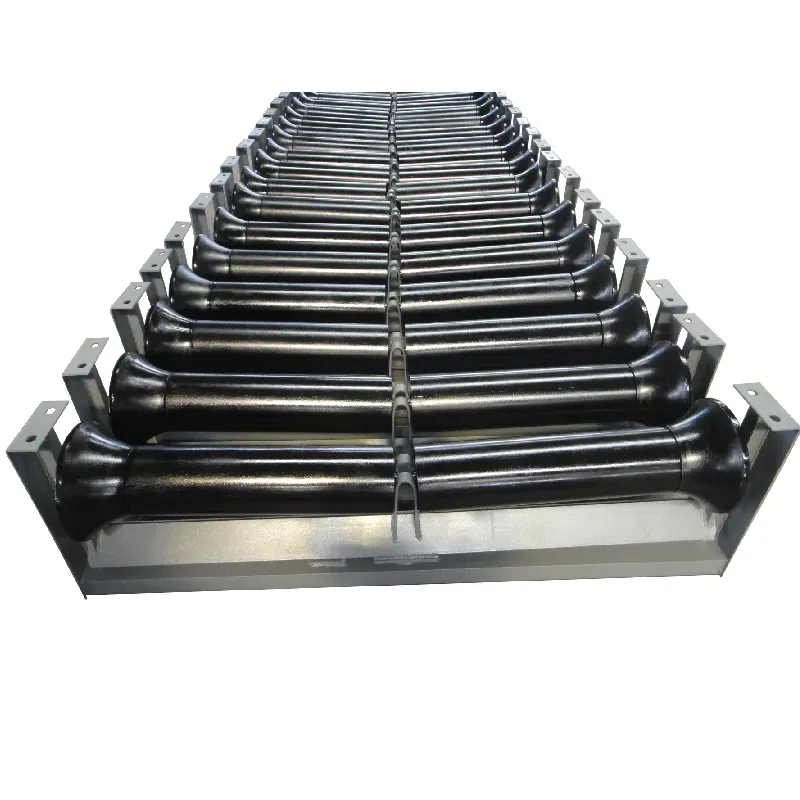

Zulu self cleaning return idlers

The Importance of Self-Cleaning Return Idlers in Modern Conveyor Systems

Conveyor systems are a backbone of many industries, facilitating the efficient movement of materials in manufacturing, mining, and logistics. Within these systems, the components that ensure smooth operation are vital. One such component is the return idler, which plays a crucial role in supporting the return side of the conveyor belt. Recently, the concept of self-cleaning return idlers has gained traction due to their significant advantages over traditional designs.

The Importance of Self-Cleaning Return Idlers in Modern Conveyor Systems

One of the main benefits of self-cleaning return idlers is the reduction in maintenance costs. In conventional systems, operators often need to schedule regular maintenance to clear built-up debris. This can be time-consuming and costly, not to mention a disruption to production schedules. With self-cleaning idlers, the need for frequent manual cleaning is significantly reduced. The design often includes features such as grooves, angled surfaces, or scraping mechanisms that automatically dislodge and direct materials back into the flow of the production line.

self cleaning return idlers

In addition to lowering maintenance requirements, self-cleaning return idlers enhance the overall efficiency of conveyor systems. They facilitate a smoother operation by ensuring that the belt maintains its intended path and does not encounter resistance from accumulated materials. This results in decreased wear and tear on the belt itself, which extends its lifespan and contributes positively to the bottom line. Moreover, a well-maintained and clean conveyor system translates to faster throughput, enabling companies to meet production demands promptly.

Another important aspect to consider is the environmental impact. In industries where materials are potentially hazardous, such as mining or chemical manufacturing, the build-up of debris can pose serious safety and environmental concerns. Self-cleaning return idlers significantly mitigate these risks by ensuring that materials do not leach into the surrounding environment. By improving the overall cleanliness of the conveyor system, companies not only adhere to safety regulations but also promote a more sustainable operation.

Furthermore, the adaptability of self-cleaning return idlers cannot be overlooked. They can be engineered to fit various conveyor sizes and configurations, making them a versatile solution for a wide range of applications. Whether one is dealing with heavy-duty bulk materials or lighter items, these idlers can be tailored to meet the specific needs of the operation, offering flexibility that traditional idlers may lack.

In conclusion, self-cleaning return idlers represent a significant advancement in conveyor technology. Their ability to minimize maintenance, improve operational efficiency, and promote environmental safety makes them an essential component in modern industrial applications. As companies continue to seek ways to optimize their processes and reduce costs, the adoption of self-cleaning technology in return idlers will undoubtedly become a standard practice. By investing in these innovative systems, industries can not only enhance productivity but also set new standards for operational excellence in a competitive landscape.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025