Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

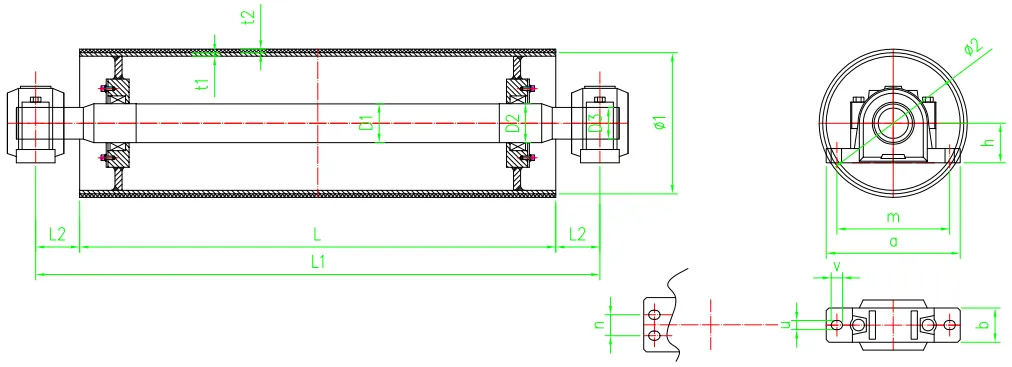

Zulu self cleaning return idlers

The Importance of Self-Cleaning Return Idlers in Conveyor Systems

In modern industrial settings, the efficiency and reliability of conveyor systems are paramount. Among the numerous components that contribute to the smooth operation of these systems, self-cleaning return idlers have gained significant attention. These specialized idlers play a critical role in maintaining the performance and longevity of conveyor belts, particularly in harsh operational environments.

What are Self-Cleaning Return Idlers?

Self-cleaning return idlers are designed to minimize the buildup of material on the return side of conveyor belts. Positioned strategically in the conveyor system, these idlers help to dislodge and remove sticky materials that would otherwise accumulate. This buildup can lead to various operational issues, including belt misalignment, increased wear and tear, and even downtime due to maintenance requirements.

How Do They Work?

The functionality of self-cleaning return idlers is rooted in their innovative design. Unlike traditional idlers, which may allow material to adhere to their surfaces, self-cleaning idlers incorporate features that facilitate the removal of debris. These may include tapered shapes, rotating elements, or specially engineered surface textures. As the conveyor belt travels over these idlers, the design disrupts the adherence of materials, effectively scraping them away and preventing clogs.

Benefits of Self-Cleaning Return Idlers

self cleaning return idlers

1. Reduced Maintenance Costs By minimizing material buildup, self-cleaning return idlers significantly reduce the need for frequent maintenance. This not only lowers operational costs but also increases the availability of the conveyor system.

2. Enhanced Conveyor Efficiency A clean return path ensures that the conveyor belt runs smoothly without unnecessary friction or resistance. This leads to improved energy efficiency and better overall performance.

3. Improved Safety Material accumulation on return idlers can create hazards in the workplace. By ensuring a clean and clear operational area, self-cleaning idlers enhance safety for workers and machinery alike.

4. Extended Equipment Lifespan By preventing material buildup and reducing wear on the belt and idlers, these components contribute to a longer lifespan for the entire conveyor system. This translates to further cost savings over time.

5. Versatility Self-cleaning return idlers are suitable for a wide range of materials and industries, from mining to waste management. Their adaptability makes them a preferred choice in various settings where material buildup is a concern.

Conclusion

In conclusion, self-cleaning return idlers are a vital innovation in the field of conveyor systems. By addressing the challenges associated with material buildup, these components enhance the efficiency, safety, and longevity of conveyor operations. As industries continue to evolve and demand higher standards of performance, the adoption of self-cleaning technologies will become increasingly essential. Businesses that invest in these advanced idlers position themselves for success, ensuring that their conveyor systems operate at peak efficiency while minimizing downtime and maintenance costs. The future of material handling lies in the integration of such innovative solutions, making self-cleaning return idlers a valuable asset in any industrial operation.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025