Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 17, 2025 18:17

Back to list

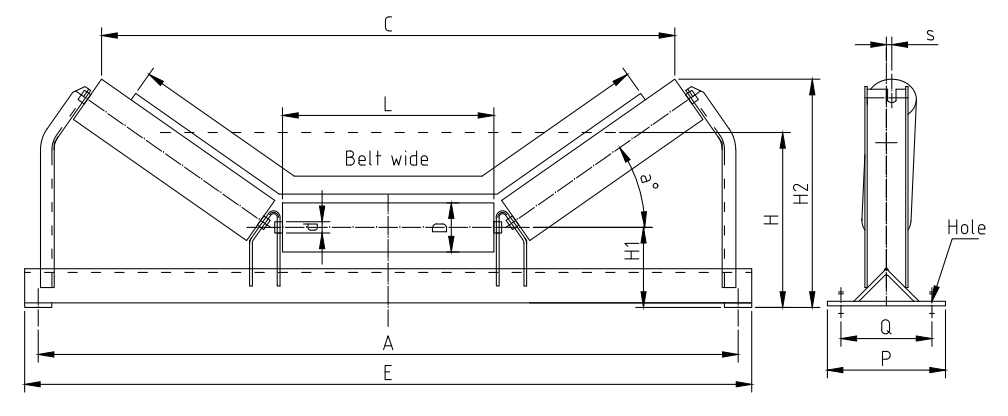

self aligning idler

Navigating the complexities of conveyor systems can be a challenging endeavor, especially if any part of the setup is not functioning optimally. Among many integral components of a conveyor system, self-aligning idlers hold a unique position, pivotal not just to the efficiency but also to the longevity of the overall system. This article elucidates the importance, technical nuances, and benefits of incorporating self-aligning idlers into your conveyor operations, targeted at enhancing product handling efficiency and lifecycle.

Authoritatively, self-aligning idlers are sanctioned and recommended by industry leaders and associations focused on bulk material handling efficiency. Numerous technical papers and case studies underscore their effectiveness in promoting operational safety and reducing unforeseen maintenance. These testimonial endorsements give credence to their reliability and indispensable role in modern material handling systems. One cannot ignore the heightened emphasis on sustainability in today’s industrial landscape. Self-aligning idlers contribute significantly towards achieving eco-friendly operations by reducing unnecessary energy consumption that arises from misaligned belts. Such efficiency enhancements align well with broader environmental goals, facilitating compliance with global sustainability standards and reducing a company's carbon footprint. Trust in the efficacy of self-aligning idlers is also bolstered by the rigorous testing they undergo during product development stages. Manufacturers invest heavily in research and testing to emulate various operational conditions, ensuring that the final product delivers consistent performance across diverse scenarios. Conclusively, the integration of self-aligning idlers into conveyor systems cannot be overstated. From marrying operational efficiency with cost savings to endorsing safety and sustainability, the role of self-aligning idlers is multidimensional and paramount. Approaching this with a nuanced understanding and strategic implementation can trailblaze advancements in operational excellence and extend the lifecycle of the entire conveyor system. When it comes to elevating conveyor efficiency, investing in self-aligning idlers is not just a recommendation—it's a proactive strategy for success.

Authoritatively, self-aligning idlers are sanctioned and recommended by industry leaders and associations focused on bulk material handling efficiency. Numerous technical papers and case studies underscore their effectiveness in promoting operational safety and reducing unforeseen maintenance. These testimonial endorsements give credence to their reliability and indispensable role in modern material handling systems. One cannot ignore the heightened emphasis on sustainability in today’s industrial landscape. Self-aligning idlers contribute significantly towards achieving eco-friendly operations by reducing unnecessary energy consumption that arises from misaligned belts. Such efficiency enhancements align well with broader environmental goals, facilitating compliance with global sustainability standards and reducing a company's carbon footprint. Trust in the efficacy of self-aligning idlers is also bolstered by the rigorous testing they undergo during product development stages. Manufacturers invest heavily in research and testing to emulate various operational conditions, ensuring that the final product delivers consistent performance across diverse scenarios. Conclusively, the integration of self-aligning idlers into conveyor systems cannot be overstated. From marrying operational efficiency with cost savings to endorsing safety and sustainability, the role of self-aligning idlers is multidimensional and paramount. Approaching this with a nuanced understanding and strategic implementation can trailblaze advancements in operational excellence and extend the lifecycle of the entire conveyor system. When it comes to elevating conveyor efficiency, investing in self-aligning idlers is not just a recommendation—it's a proactive strategy for success.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS