Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

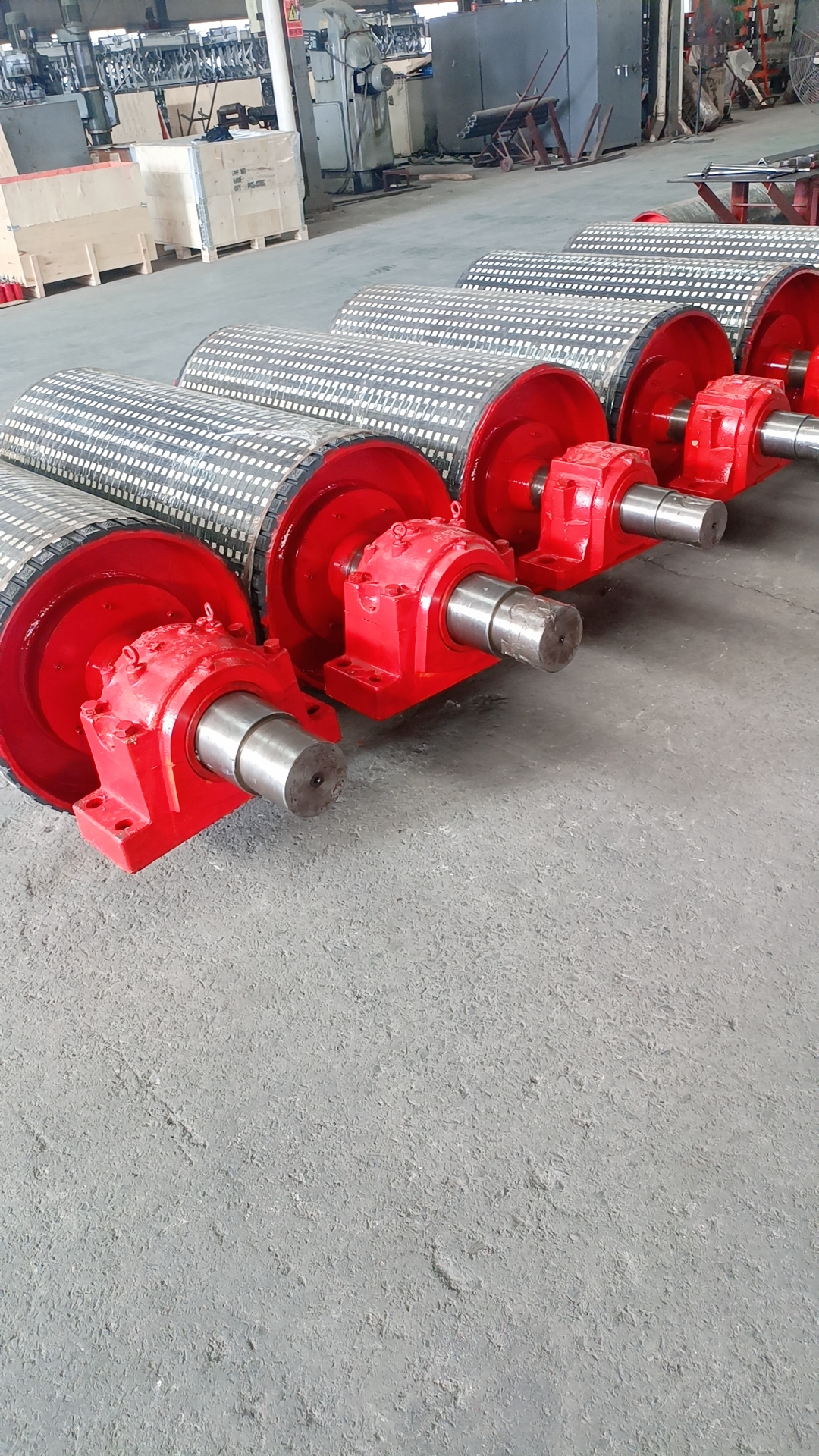

Zulu Self-Aligning Conveyor Rollers for Enhanced Material Handling Efficiency and Performance

Self-Aligning Conveyor Rollers Revolutionizing Material Handling

In today’s fast-paced industrial environment, the efficiency and reliability of material handling systems are more critical than ever. A significant innovation contributing to these systems is the development of self-aligning conveyor rollers. These specialized rollers are not only designed to enhance the performance of conveyor systems but also to extend their lifespan and reduce maintenance costs. This article explores the functionality, benefits, and applications of self-aligning conveyor rollers in modern industries.

What Are Self-Aligning Conveyor Rollers?

Self-aligning conveyor rollers are engineered to maintain proper alignment along a conveyor belt, thus minimizing issues related to misalignment. Traditional conveyor systems often face challenges such as belt drift, wear, and irregular load distribution caused by misalignment, which can lead to inefficiencies and costly downtime. Self-aligning rollers are equipped with a design that allows them to adapt to the belt's position dynamically, ensuring optimal alignment at all times.

Functionality and Design Features

The core feature of self-aligning rollers is their ability to pivot and adjust under varying loads and operational conditions. Unlike standard rollers that are fixed in position, self-aligning rollers utilize a flexible mounting system that allows for lateral movement. This design prevents the conveyor belt from veering off track, regardless of the load being transported.

Typically, these rollers come with tapered or crowned surfaces, which naturally guide the conveyor belt back to the center when it starts to drift. Additionally, self-aligning rollers can be constructed from a variety of materials, including rubber, urethane, or steel, offering versatility for different applications and environments.

Advantages of Self-Aligning Conveyor Rollers

1. Reduced Maintenance Traditional conveyor systems often require frequent adjustments and alignments. By incorporating self-aligning rollers, companies can significantly reduce maintenance costs associated with manual adjustments and repairs, leading to less downtime and increased productivity.

self aligning conveyor rollers

2. Enhanced Durability Self-aligning rollers are designed to withstand harsh operational environments. Their robust construction and ability to self-adjust mean that they experience less wear and tear compared to conventional rollers, extending their life span and reliability.

3. Improved Safety Misalignment can create hazardous situations, such as unexpected belt slippage or object spillage. The self-aligning nature of these rollers helps ensure that the conveyor operates smoothly, thereby minimizing safety risks for workers.

4. Optimized Material Flow By maintaining consistent alignment, self-aligning rollers facilitate smoother material handling. This optimization leads to increased efficiency in transporting goods, reducing the chances of bottlenecks in production lines.

Applications Across Industries

Self-aligning conveyor rollers are versatile and can be employed in a variety of industries. They are commonly used in

- Mining and Quarrying The robust nature of these rollers makes them ideal for transporting heavy materials in challenging environments. - Food and Beverage Hygiene standards are critical in this sector, and self-aligning rollers can be made from materials that meet stringent regulatory requirements. - Manufacturing In manufacturing plants, self-aligning rollers ensure that the transfer of components is smooth and efficient, thereby enhancing overall production timeliness.

Conclusion

Self-aligning conveyor rollers are an essential innovation in the realm of material handling, offering significant advantages over traditional systems. Their ability to maintain proper alignment reduces maintenance costs, enhances safety, and improves material flow efficiency. As industries strive for greater productivity and reliability, the adoption of self-aligning conveyor rollers will likely continue to grow, solidifying their role as a cornerstone of modern conveyor technology. Embracing this technology not only revolutionizes how materials are handled but also contributes to a safer and more efficient working environment.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025