Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 25, 2025 05:00

Back to list

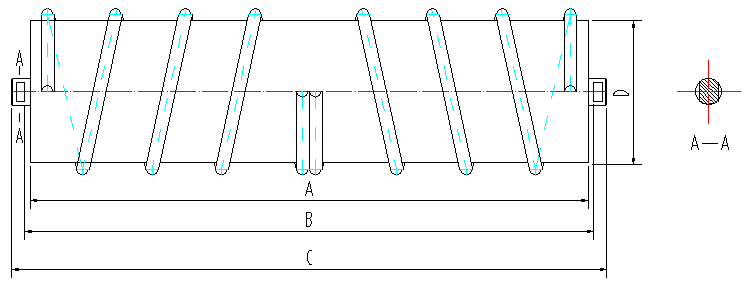

AH Flanging Bearing Housing

Sealed bearing housings play an essential role in enhancing the performance and longevity of machinery across various industries. Their unique design and construction offer invaluable benefits, not only in terms of functionality but also through their ability to reduce maintenance costs and downtime. This article delves into why they are indispensable in modern mechanical applications.

Trustworthiness is another essential aspect of sealed bearing housings. Manufacturers often subject their products to rigorous testing to ensure they meet the stringent industry standards. Certifications and compliance with international norms such as ISO standards further validate their reliability and performance. For consumers, opting for products that adhere to these standards is a testament to their quality and expected lifespan. From a consumer experience perspective, the usability and installation of sealed bearing housings have also seen improvements. Manufacturers have designed housings for easy installation and maintenance, which is crucial for reducing machine downtime. Coupled with detailed user manuals and support from technical teams, end-users can effortlessly integrate these components into their machinery. In conclusion, the implementation of sealed bearing housings is not merely a trend but a strategic decision for businesses aiming to optimize operations and reduce expenditures. Their engineering excellence coupled with proven reliability makes them an invaluable component in ensuring efficient, smooth, and uninterrupted machinery function. As technology advances, further innovations in this domain will undoubtedly continue to support industrial growth and efficiency. Moreover, as industries continue to demand higher efficiency and reliability from their machinery, the role of sealed bearing housings will become even more significant. Thus, businesses seeking long-term reliability, cost savings, and improved performance should look no further than incorporating these essential components into their systems.

Trustworthiness is another essential aspect of sealed bearing housings. Manufacturers often subject their products to rigorous testing to ensure they meet the stringent industry standards. Certifications and compliance with international norms such as ISO standards further validate their reliability and performance. For consumers, opting for products that adhere to these standards is a testament to their quality and expected lifespan. From a consumer experience perspective, the usability and installation of sealed bearing housings have also seen improvements. Manufacturers have designed housings for easy installation and maintenance, which is crucial for reducing machine downtime. Coupled with detailed user manuals and support from technical teams, end-users can effortlessly integrate these components into their machinery. In conclusion, the implementation of sealed bearing housings is not merely a trend but a strategic decision for businesses aiming to optimize operations and reduce expenditures. Their engineering excellence coupled with proven reliability makes them an invaluable component in ensuring efficient, smooth, and uninterrupted machinery function. As technology advances, further innovations in this domain will undoubtedly continue to support industrial growth and efficiency. Moreover, as industries continue to demand higher efficiency and reliability from their machinery, the role of sealed bearing housings will become even more significant. Thus, businesses seeking long-term reliability, cost savings, and improved performance should look no further than incorporating these essential components into their systems.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS