Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 14, 2025 12:57

Back to list

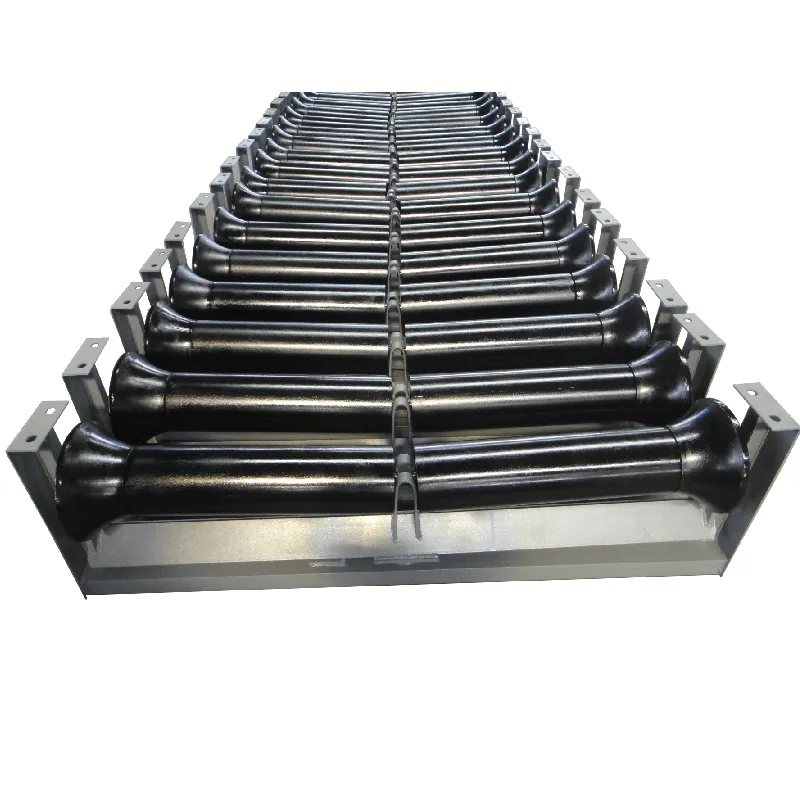

rubber impact roller

Rubber impact rollers are vital components in industries such as mining, logistics, and manufacturing, where they play a pivotal role in material handling systems. Their design and functionality not only facilitate efficient transport of goods but also enhance operational reliability. Understanding the multifaceted benefits and technical nuances of rubber impact rollers can empower businesses to optimize their industrial processes effectively.

From an engineering perspective, the customization of rubber impact rollers is another substantial benefit. They can be tailored to meet specific requirements depending on the application, such as differing load capacities, environmental conditions, and material handling needs. This versatility ensures a perfect fit within diverse industrial settings, enhancing the overall efficiency of material handling systems. The expertise involved in selecting and implementing rubber impact rollers is paramount. Industry professionals, with years of experience, can guide businesses through the selection process, ensuring that every aspect—from roller alignment to load distribution—is optimized for peak performance. This expert guidance is foundational in achieving improved throughput and minimizing operational hitches. Trustworthiness and authority in the realm of rubber impact rollers are upheld by extensive testing and certification processes. Reputable manufacturers provide detailed technical documentation, performance data, and compliance certifications, which reinforce the reliability of their products. Engaging with certified suppliers and manufacturers ensures that businesses acquire rollers that meet rigorous industry standards. Real-world case studies underline the transformative impact of integrating rubber impact rollers into complex conveyor systems. Companies have reported significant drops in maintenance needs and operation expenses post-implementation. These testimonials serve as compelling evidence of the tangible benefits these rollers provide, further instilling confidence in their application. In conclusion, rubber impact rollers are indispensable in modern industrial operations, offering unmatched resilience, adaptability, and efficiency. Their capability to mitigate material handling challenges allows businesses to streamline their processes and achieve sustained operational success. By investing in high-quality rubber impact rollers, companies not only enhance their production efficiency but also ensure long-term savings and resource optimization.

From an engineering perspective, the customization of rubber impact rollers is another substantial benefit. They can be tailored to meet specific requirements depending on the application, such as differing load capacities, environmental conditions, and material handling needs. This versatility ensures a perfect fit within diverse industrial settings, enhancing the overall efficiency of material handling systems. The expertise involved in selecting and implementing rubber impact rollers is paramount. Industry professionals, with years of experience, can guide businesses through the selection process, ensuring that every aspect—from roller alignment to load distribution—is optimized for peak performance. This expert guidance is foundational in achieving improved throughput and minimizing operational hitches. Trustworthiness and authority in the realm of rubber impact rollers are upheld by extensive testing and certification processes. Reputable manufacturers provide detailed technical documentation, performance data, and compliance certifications, which reinforce the reliability of their products. Engaging with certified suppliers and manufacturers ensures that businesses acquire rollers that meet rigorous industry standards. Real-world case studies underline the transformative impact of integrating rubber impact rollers into complex conveyor systems. Companies have reported significant drops in maintenance needs and operation expenses post-implementation. These testimonials serve as compelling evidence of the tangible benefits these rollers provide, further instilling confidence in their application. In conclusion, rubber impact rollers are indispensable in modern industrial operations, offering unmatched resilience, adaptability, and efficiency. Their capability to mitigate material handling challenges allows businesses to streamline their processes and achieve sustained operational success. By investing in high-quality rubber impact rollers, companies not only enhance their production efficiency but also ensure long-term savings and resource optimization.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS