Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Exploring the Benefits of Rubber Impact Rollers in Modern Manufacturing Processes

The Importance of Rubber Impact Rollers in Modern Industries

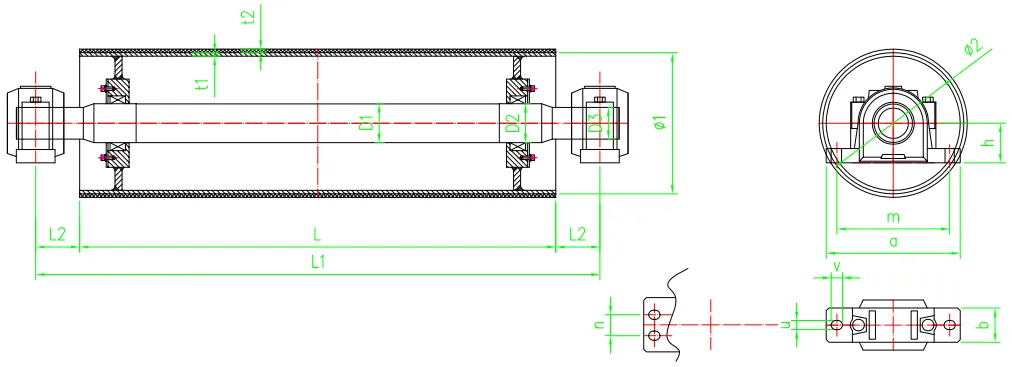

Rubber impact rollers play a crucial role in various industrial applications, contributing significantly to operational efficiency and equipment longevity. These specialized components are designed to absorb and dissipate energy, thereby reducing stress on machinery and minimizing wear and tear. As industries continue to evolve and demand higher levels of performance, the use of rubber impact rollers has become increasingly prevalent.

One of the primary advantages of rubber impact rollers is their ability to mitigate vibration and shock caused by heavy loads and dynamic operations

. In conveyor systems, for instance, these rollers serve as a buffer between the product and the machinery, providing a smoother transition and preventing damage to both. This is particularly vital in industries such as mining, agriculture, and manufacturing, where heavy materials are frequently transported. By absorbing impacts, rubber rollers protect the integrity of the conveyor system and extend its lifespan, ultimately resulting in cost savings for businesses.rubber impact roller

Additionally, rubber impact rollers are essential in ensuring safety in industrial environments. The cushioning effect of rubber helps to prevent accidents caused by sudden jolts or drops in items being transported. This feature is particularly important in high-traffic areas where forklifts and other machinery operate. By minimizing the risk of falling objects and equipment malfunction, rubber impact rollers contribute to a safer workplace for employees, which is an invaluable aspect of any operational strategy.

Another significant benefit of using rubber impact rollers is their versatility. They can be manufactured in various sizes and hardness levels to meet specific application requirements. This flexibility allows industries to select the most appropriate roller for their unique needs, whether it be for heavy-duty applications or lighter operations. Furthermore, advancements in rubber technology have led to the development of rollers that resist abrasion, chemicals, and extreme temperatures, enhancing their usability across diverse environments.

In conclusion, the integration of rubber impact rollers into industrial systems is not merely a matter of convenience but a strategic decision that enhances performance, safety, and durability. As businesses strive to improve their operational workflows and reduce maintenance costs, the demand for these essential components will likely continue to grow. By investing in high-quality rubber impact rollers, companies can ensure that their equipment operates efficiently and reliably, ultimately supporting their long-term success in an increasingly competitive market.