Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu rubber disc roller

The Versatility and Importance of Rubber Disc Rollers

Rubber disc rollers are integral components in a variety of industrial applications, ranging from manufacturing to agriculture, and even in the automation of conveyor systems. Their design, characterized by a cylindrical form made from elastomeric compounds, provides them with unique properties that make them suitable for numerous tasks. In this article, we will explore the versatility, functionality, and importance of rubber disc rollers in various sectors.

What Are Rubber Disc Rollers?

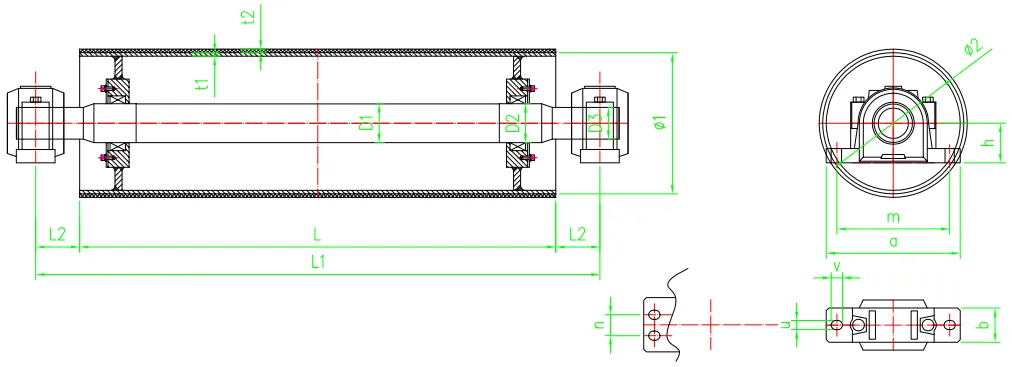

Rubber disc rollers are rolling elements that consist of a circular rubber disc mounted on a shaft. These rollers can differ significantly in size, hardness, and surface texture depending on their intended application. The rubber material allows for flexibility in the performance of tasks, enabling these rollers to adapt to various conditions, such as load weights and surface types.

Key Features

One of the primary features of rubber disc rollers is their ability to absorb shock and vibration. This cushions the materials being transferred, reducing the risk of damage. Moreover, rubber possesses excellent gripping capabilities, which enhance the traction between the roller and the materials it interacts with. As a result, rubber disc rollers are particularly effective in conveyor systems where stability and control are vital.

Another notable feature is their resistance to wear and degradation. Rubber can withstand harsh environments, making rubber disc rollers suitable for outdoor applications, as they can endure fluctuations in temperature, moisture, and chemical exposure. This durability significantly reduces maintenance costs and enhances operational efficiency.

Applications Across Industries

1. Manufacturing In industrial manufacturing, rubber disc rollers are widely used in material handling systems, where they guide products along conveyor lines. Their ability to manage varying weights and sizes makes them invaluable in assembly lines, packaging, and sorting operations.

rubber disc roller

2. Agriculture The agricultural sector benefits from rubber disc rollers in seeders and tillers. These rollers assist in the smooth operation of machinery while planting seeds or performing soil preparation tasks. Their design allows for consistent seed depth and spacing, ensuring optimal growth conditions for crops.

3. Construction In construction, rubber disc rollers are employed in a variety of machinery, from compactors to pavers. They ensure that materials are moved efficiently and compacted effectively, laying the groundwork for further construction processes.

4. Automotive The automotive industry utilizes rubber disc rollers in conveyor belts used for vehicle assembly. Their resilience to wear ensures the smooth transportation of parts throughout the assembly line, which is crucial for maintaining production efficiency.

5. Slaughterhouses and Food Processing Plants Due to their non-slip characteristics and ease of cleaning, rubber disc rollers are often used in food processing. They reduce the chances of contamination while maintaining the integrity of food products.

Environmental Considerations

As industries become increasingly aware of their environmental impact, the demand for sustainable materials is growing. Innovative manufacturers are now producing eco-friendly rubber disc rollers that minimize the use of harmful chemicals in their production. Furthermore, many of these rollers can be recycled, contributing to a circular economy.

Conclusion

In conclusion, rubber disc rollers are essential components with widespread applications across various industries. Their unique properties, including shock absorption, durability, and excellent grip, make them ideal for handling tasks that require precision and efficiency. As technology progresses and industries evolve, the role of rubber disc rollers is likely to expand further, supporting sustainable practices while continuing to meet the demands of modern manufacturing and automation. Understanding their significance can lead to better operational decisions and the optimization of resource management in different sectors, ultimately contributing to greater productivity and efficiency.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025