Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Rubber Disc Return Idlers for Efficient Conveyor System Performance and Durability

Rubber Disc Return Idlers An Essential Component in Bulk Material Handling

In the world of bulk material handling, the efficiency and reliability of conveyor systems are paramount. Among the various components that contribute to the smooth operation of these systems, rubber disc return idlers play a critical role. These specialized equipment pieces are designed to support and guide conveyor belts, thereby ensuring the effective movement of materials in various industrial applications.

Understanding Rubber Disc Return Idlers

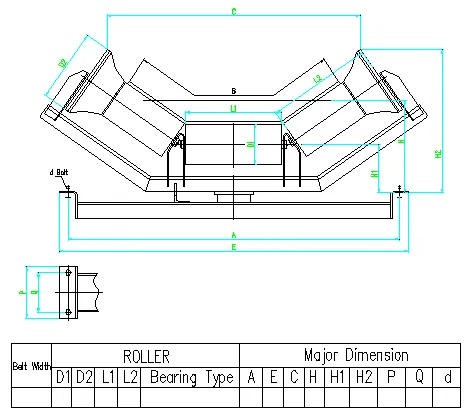

Rubber disc return idlers are a type of idler designed for use in the return section of conveyor belts. Unlike traditional idlers, which may have flat or tubular forms, rubber disc idlers feature multiple rubber discs arranged along the shaft. This unique configuration allows for a more effective and adaptable design, resulting in several key advantages over conventional idler systems.

The primary function of return idlers is to support the weight of the empty return belt while maintaining proper belt alignment. As the conveyor belt travels back to the loading point, the return idlers help keep it in position, preventing misalignment and reducing the wear and tear on the belt.

Key Benefits

1. Reduced Wear and Tear The use of rubber discs minimizes friction between the belt and the idler, which significantly reduces wear and extends the lifespan of both components. This is crucial in environments where heavy loads can cause considerable strain on the conveyor system.

rubber disc return idlers

2. Self-Cleaning Properties One of the standout features of rubber disc idlers is their ability to self-clean. The rubber discs help dislodge and remove material that may adhere to the belt as it returns. This self-cleaning action reduces the risk of material buildup, which can cause belt misalignment and operational inefficiencies.

3. Improved Load Distribution The design of rubber disc return idlers allows for a better distribution of the load across the idler. This means less concentrated pressure on any single point, leading to improved wear characteristics and enhanced support for the belt.

4. Noise Reduction Rubber has excellent shock-absorbing qualities, which help reduce vibration and noise as the conveyor system operates. In industries where noise pollution is a concern, rubber disc return idlers provide a quieter solution compared to metal idlers.

5. Cost-Effectiveness While the initial investment in rubber disc return idlers may be higher than traditional options, the long-term savings realized through reduced maintenance, fewer replacements, and increased efficiency make them a cost-effective choice for many operations.

Applications

Rubber disc return idlers are widely used across various industries, including mining, agriculture, construction, and logistics. Their versatility makes them suitable for different types of materials, from granular substances to large bulk items. Whether transporting coal, grains, or aggregates, rubber disc return idlers help ensure the efficient movement of goods through conveyor systems.

In conclusion, rubber disc return idlers are an indispensable component in modern bulk material handling systems. Their innovative design offers numerous advantages, including reduced wear, self-cleaning properties, improved load distribution, and noise reduction. As industries continue to seek ways to enhance operational efficiency, the adoption of rubber disc return idlers is likely to grow, solidifying their place as a key element in conveyor technology. By investing in high-quality idlers, companies can ensure smoother operations and a longer lifespan for their conveyor systems, ultimately leading to better productivity and reduced costs.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025