Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu rubber belt pulley

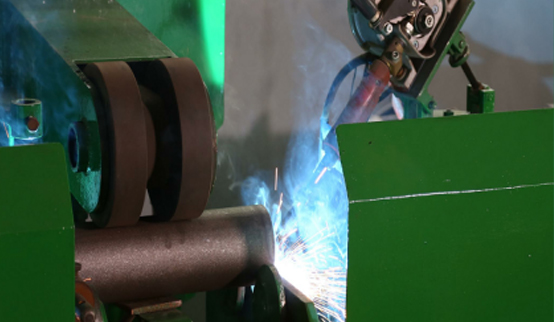

Understanding Rubber Belt Pulleys An Essential Component for Power Transmission

Rubber belt pulleys play a critical role in various mechanical systems, providing a reliable method for power transmission in numerous industrial and commercial applications. These components are widely used in machines ranging from conveyor systems in factories to agricultural equipment and automotive systems. Understanding the functionality, benefits, and maintenance of rubber belt pulleys is essential for anyone involved in engineering or machinery design.

At its core, a rubber belt pulley is designed to transfer mechanical power between two shafts using a flexible rubber belt. This design allows for the efficient transfer of energy by reducing slippage between the belt and the pulley surface. Typically, rubber belts are favored over metal counterparts due to their superior grip, flexibility, and noise-dampening properties. This makes rubber belt pulleys ideal for systems where loud operations can be disruptive.

The primary advantage of rubber belt pulleys lies in their ability to absorb shock and vibrations. In any mechanical system, sudden changes in load can lead to significant stress on components, potentially causing damage over time. The elasticity of rubber helps to mitigate these forces, enhancing the longevity and reliability of machinery. Furthermore, the smooth operation of rubber belts reduces wear and tear, leading to decreased maintenance costs and increased uptime.

rubber belt pulley

Installation and maintenance of rubber belt pulleys are straightforward, making them a popular choice among engineers and maintenance professionals. Proper alignment of the pulleys and tensioning of the belt are essential for optimal performance. Regular inspections can help identify wear and tear, ensuring that the system remains functional over time. In most cases, replacing a worn-out belt is a simple task that can significantly extend the pulley’s lifecycle.

Applications for rubber belt pulleys are vast and varied. In manufacturing, they’re commonly used in conveyor systems to move products along assembly lines. In automotive applications, they play an essential role in driving various engine components, such as alternators and water pumps. Additionally, they are found in agricultural machinery, contributing to the efficient operation of equipment like harvesters and tractors.

In conclusion, rubber belt pulleys are indispensable components in modern machinery. Their ability to provide smooth and efficient power transmission, combined with their durability and ease of maintenance, makes them a preferred choice in numerous applications. Understanding the importance of these pulleys can lead to better design and maintenance practices, ultimately improving overall system performance and reliability. Whether in industry or agriculture, rubber belt pulleys continue to be a cornerstone of effective mechanical design.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025