Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

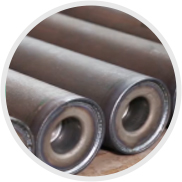

Zulu High-Quality Rubber Belt Pulleys for Optimal Performance

The Importance of Rubber Belt Pulleys in Modern Machinery

Rubber belt pulleys are integral components in various mechanical systems, playing a crucial role in the transmission of power and movement across multiple applications. These pulleys are designed to work in conjunction with rubber belts, which are known for their durability, flexibility, and high friction coefficient. This combination enhances efficiency and reliability in myriad industrial settings.

One of the primary functions of rubber belt pulleys is to facilitate the transfer of motion between shafts. In machinery such as conveyors, fans, and agricultural equipment, rubber belts provide a means to transmit power from an engine or motor to the working components. The elasticity of rubber allows the belt to maintain a tight grip on the pulley, ensuring smooth operation and reducing the risk of slippage. This is particularly important in applications where consistent speed and torque are vital for optimal performance.

Rubber belt pulleys also contribute to the longevity of machinery. Traditional metal pulleys can lead to premature wear on belts due to their rigid surfaces, which can cause excessive friction and heat generation. In contrast, rubber pulleys are designed to absorb shocks and vibrations, which significantly decreases wear and tear on both the pulleys and belts. This results in lower maintenance costs and longer service intervals for equipment, making rubber belt systems a more economical choice in the long run.

rubber belt pulley

Moreover, rubber belt pulleys are versatile. They come in various shapes and sizes, adapting to different machinery requirements. Their designs can accommodate variable speeds and loads, making them suitable for industries ranging from manufacturing to automotive. The ease of installation and replacement also adds to their appeal, as operators can quickly swap out a worn pulley without extensive downtime, ensuring that production schedules remain on track.

In recent years, advances in material science have led to the development of specially formulated rubber compounds that enhance the performance of these pulleys. These modern materials exhibit superior resistance to heat, abrasion, and chemicals, further extending the lifespan of rubber belt systems. Innovations in manufacturing techniques have also made it possible to produce pulleys that are lighter yet stronger, contributing to overall energy savings in equipment operation.

In conclusion, rubber belt pulleys are essential for efficient machinery operation across various industries. By providing effective power transmission, enhancing equipment longevity, and offering versatility in design, they play a pivotal role in modern engineering solutions. As technology continues to evolve, the importance of these components will only continue to grow, ensuring that they remain a fundamental part of mechanical design and function in the future.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025