Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Innovative Roller Seal Designs for Enhanced Performance and Durability in Various Applications

The Importance of Roller Seals in Modern Engineering

In the rapidly evolving world of engineering and manufacturing, the need for efficient and reliable sealing solutions has become increasingly crucial. One of the most innovative and effective sealing technologies that have emerged is the roller seal. This type of seal, which integrates the principles of rolling motion with sealing functionalities, presents a versatile solution for various industrial applications.

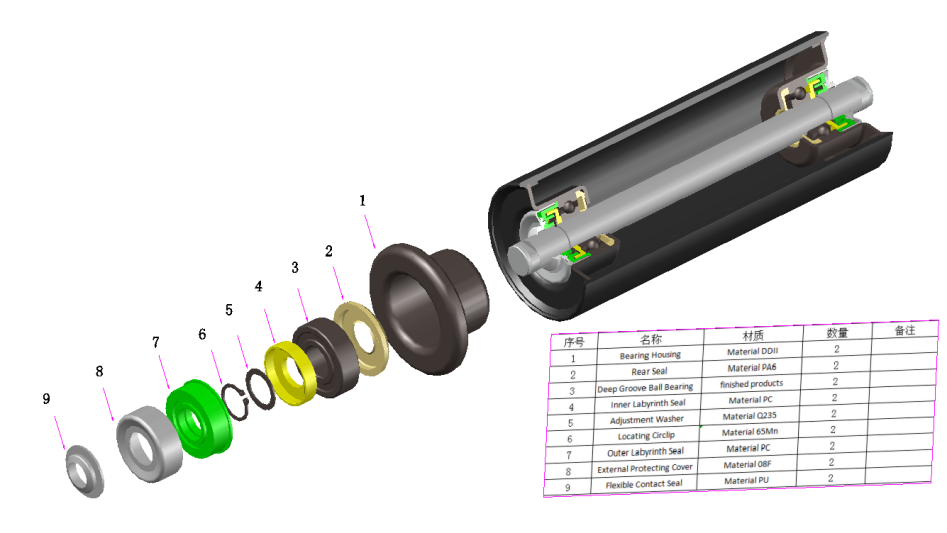

Understanding Roller Seals

Roller seals are designed to provide a reliable barrier against contaminants while allowing for rotational movement. Unlike traditional static seals, roller seals use a series of rollers or wheels, which reduce friction and wear, thereby enhancing their longevity and performance. This mechanical design helps to maintain tight tolerances between moving parts, preventing leaks of fluids or gases in dynamic applications.

Applications in Various Industries

Roller seals are employed across multiple industries due to their adaptable nature. In the automotive sector, for instance, they are crucial for ensuring that engine components operate smoothly without loss of fluid or pressure. These seals are used in power steering systems, transmissions, and various other applications, where they help improve efficiency and reduce maintenance costs.

In the aerospace industry, roller seals play a vital role in ensuring the integrity of systems that operate under extreme conditions

. The ability of roller seals to withstand high pressures and temperatures makes them suitable for applications in jet engines and hydraulic systems. Their reliability not only enhances performance but also contributes to safety, which is paramount in aviation.roller seal

Similarly, in the oil and gas sector, roller seals are essential for managing the challenges associated with high-pressure environments. They provide effective sealing solutions for valves and pipelines, preventing leaks that could lead to significant environmental hazards and economic losses.

Benefits of Roller Seals

One of the standout advantages of roller seals is their ability to minimize friction, which in turn leads to less wear and tear on both the seal and the mating surfaces. This reduction in friction translates to lower energy consumption and improved efficiency, aligning with the growing demand for sustainable manufacturing practices. Additionally, roller seals can be designed to accommodate a wide range of operating conditions, which makes them suitable for various specialized applications.

Furthermore, the ease of installation and maintenance of roller seals is a critical factor for engineers and maintenance personnel. Their design often allows for quick replacement or adjustment, minimizing downtime and enhancing productivity.

Conclusion

In summary, roller seals represent a significant advancement in sealing technology. Their ability to provide reliable, efficient, and adaptable solutions makes them indispensable in modern engineering applications. As industries continue to seek innovative solutions to improve performance and sustainability, roller seals are likely to play an increasingly vital role in shaping the future of mechanical design and industrial manufacturing. Their benefits not only contribute to operational efficiency but also support broader goals related to safety and environmental protection, making them a key component in the evolving landscape of technology.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025