Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu roller lagging

Understanding Roller Lagging A Key Component in Conveyor Systems

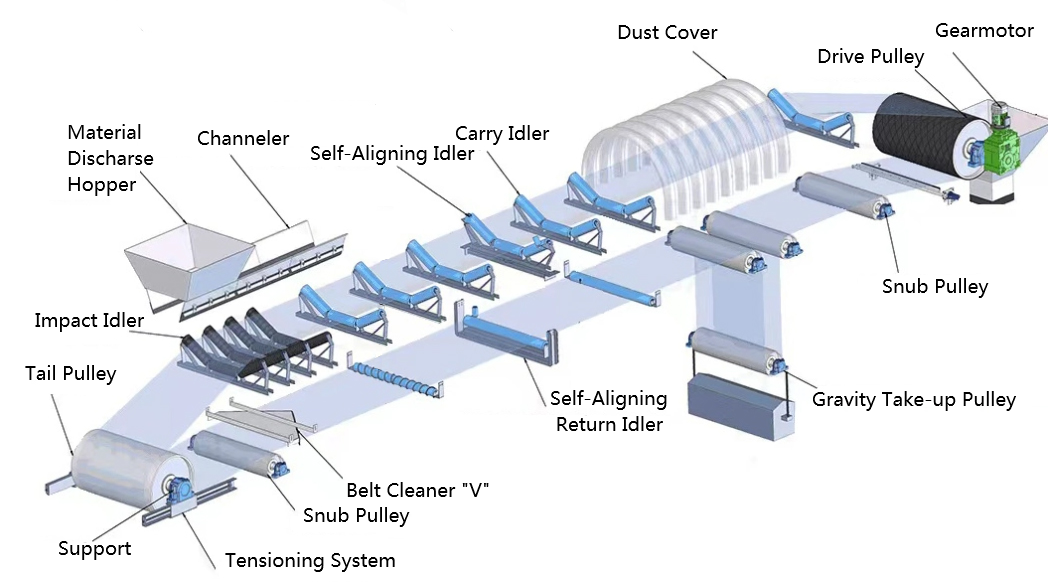

Roller lagging is a critical aspect of conveyor systems, significantly impacting their efficiency and durability. In industrial applications, conveyor systems are used extensively to transport materials across different processes, and any failure in these systems can lead to significant downtime and economic losses. Thus, understanding roller lagging is essential for anyone involved in the maintenance and management of conveyor operations.

Roller lagging refers to the process of applying a material, usually rubber or another resilient substance, to the surface of conveyor rollers. This application serves multiple purposes, notably improving the friction between the conveyor belt and the roller, enhancing grip, and reducing slippage. The choice of lagging material can vary depending on the specific application—factors like the type of material being transported, environmental conditions, and the wear and tear expected over time all play a role in this decision.

One of the primary benefits of roller lagging is the improvement it brings to the overall efficiency of the conveyor system. A well-lagged roller ensures that the belt maintains a strong grip, especially when handling heavy or slippery materials. This enhancement in grip reduces the likelihood of the belt slipping off the rollers, which can lead to misalignment, increased wear on the belt, and ultimately, system failure.

Another significant advantage of roller lagging is its role in protecting the rollers themselves. Conveyor rollers are typically subject to significant wear and tear due to the constant movement of heavy materials. Lagging acts as a protective layer, absorbing impacts and reducing the surface wear on the roller. This prolongs the life of both the rollers and the conveyor belt, ultimately saving money on repairs and replacements.

roller lagging

Moreover, roller lagging contributes to noise reduction in conveyor operations. The rubber or composite materials used in lagging can dampen vibrations and sounds produced during the transport of materials. This is particularly important in urban settings or workplaces where noise pollution regulations are in place, helping companies maintain compliance while ensuring a comfortable working environment.

The installation of roller lagging can be straightforward, but it requires careful consideration to be effective. Proper alignment and securing methods must be employed to ensure durability and performance. Regular maintenance checks are essential to monitor the condition of both the lagging and the rollers, as wear can occur over time due to continuous operation.

In addition to all these benefits, roller lagging can also be tailored for specific conditions. For instance, in situations where heat resistance is required, specialized lagging materials can be employed to withstand elevated temperatures. Similarly, when dealing with abrasive materials, using robust and wear-resistant lagging can help mitigate damage.

In conclusion, roller lagging is a vital component of efficient and reliable conveyor systems. Its benefits include improved traction, roller protection, noise reduction, and adaptability to various operational conditions. Understanding the importance of roller lagging allows maintenance teams to implement strategies that enhance system longevity and performance, leading to increased productivity and cost savings in the long run. As industry demands continue to evolve, innovations in roller lagging materials and techniques will likely play a pivotal role in the advancement of conveyor technology.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025