Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

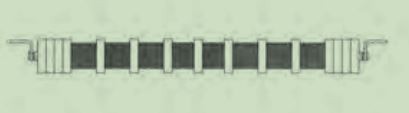

Zulu roller impact

The Dynamics of Roller Impact A Study of Forces and Effects

In the realm of physics and engineering, the concept of impact plays a crucial role in understanding how forces interact, especially in dynamic systems involving rollers, wheels, and similar mechanisms. Roller impact refers to the phenomenon that occurs when two bodies collide in such a way that one or more of them contains cylindrical shapes, like rollers. This topic not only finds applications in mechanical engineering but also has significant implications in various industries, including automotive, manufacturing, and even in the design of amusement park rides.

At its core, roller impact involves several fundamental principles of physics, particularly Newton’s laws of motion. When a roller impacts a surface or another object, the interaction can be analyzed through the lenses of momentum, energy transfer, and the resulting forces exerted during the collision. The nature of the impact—whether elastic or inelastic—determines how energy is conserved or dissipated during the event. In an elastic collision, both momentum and kinetic energy are conserved, whereas, in an inelastic collision, momentum is conserved, but kinetic energy is transformed into other forms of energy, such as heat or sound.

Understanding roller impact requires a detailed look at the factors that influence the outcome of such interactions. The material properties of the rollers, including hardness, elasticity, and surface texture, play a pivotal role in determining how they will behave upon impact. For instance, a harder roller may result in a more elastic collision, while a softer roller may lead to a more inelastic outcome, where the deformation of the roller absorbs some of the impact energy.

Moreover, the speed at which the roller approaches the impact site is crucial. Higher speeds result in greater kinetic energy, which translates to more substantial forces upon collision. This is particularly important in applications like automotive crash tests, where the resilience of components is evaluated under simulated impact conditions. Engineers must ensure that materials can withstand these forces without failing, and therefore, understanding roller impact phenomena is essential for designing safer vehicles.

roller impact

Another critical factor is the angle of impact. When a roller strikes a surface at an angle rather than perpendicularly, the resulting forces can generate complex dynamics, leading to rotational motion and additional stresses that can affect both the roller and the impacted surface. This has vast implications for systems that rely on rollers, such as conveyor belts, where misalignment can lead to increased wear and tear, inefficiency, and potential failure.

In the context of amusement park rides, roller impact is also a critical consideration. The physics involved in roller coasters, for example, hinges on the dynamics of roller impact at high speeds. The thrill of these rides is derived from the careful design of transitions between heights and drops that maximize the experience while ensuring safety. Engineers must meticulously calculate potential impact forces and ensure that the materials used can handle these stresses throughout countless cycles of operation.

In manufacturing, the understanding of roller impact extends to the design of machinery that utilizes rolling elements, such as bearings and tracks. Here, the efficiency of energy transfer and the durability of components can significantly affect productivity and operational costs. Engineers employ advanced simulations and testing to analyze roller behavior under various impact conditions, leading to better designs that extend the life of parts and improve overall system reliability.

In conclusion, the study of roller impact reveals a rich interplay of physics that is essential across numerous fields. By understanding the mechanics behind these interactions—considering aspects like speed, angle, material properties, and energy transfer—engineers can innovate and design systems that are not only efficient but also safe and enduring. As technology advances and new materials are developed, the ongoing exploration of roller impact will continue to play a pivotal role in shaping the future of engineering and manufacturing, ensuring that we can meet the demands of modern society with improved performance and reliability.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025