Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu roller guides

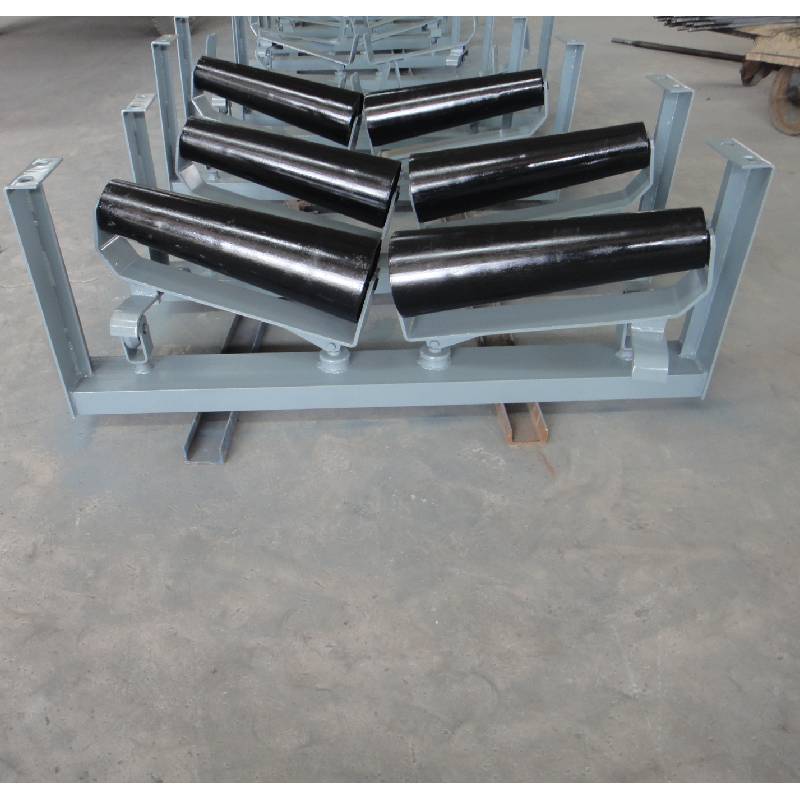

Understanding Roller Guides An Essential Component in Motion Control

In various industries, motion control is crucial for enhancing efficiency and precision in operations. One of the key components that facilitate smooth and controlled motion is the roller guide. Roller guides are mechanical devices that guide and support moving parts in machinery and equipment, ensuring that they operate smoothly, accurately, and with minimal friction.

What Are Roller Guides?

Roller guides consist of rolling elements—typically cylindrical rollers—that are housed within a track or guide. These guides are designed to support linear or rotary motion while minimizing wear and tear over time. They can be found in a wide array of applications, from manufacturing systems to automotive mechanisms and even in consumer products.

Types of Roller Guides

There are several types of roller guides, each suited to specific applications. The most common include

1. Linear Roller Guides These guides are widely used in machinery that requires precise linear motion. They allow components to move along a straight path and are often equipped with multiple rollers to distribute weight evenly. This feature reduces friction and enhances stability.

2. Rotary Roller Guides Used primarily in rotating systems, these guides facilitate smooth and continuous rotation. They are often found in applications such as conveyor belts and robotic arms.

3. Adjustment Roller Guides These guides offer the added benefit of adjustability, allowing for fine-tuning of the motion path in real-time. This adaptability is essential in complex systems where spacing and alignment may change during operation.

roller guides

Applications of Roller Guides

Roller guides play a pivotal role in various industries, including manufacturing, robotics, and transportation

. In manufacturing, they are crucial for CNC machines, ensuring that the cutting tools move with precision. In robotics, roller guides enable precise movements of robotic arms, allowing for accurate assembly and packaging processes.In the transportation sector, roller guides can be found in elevators and escalators, providing a safe and smooth experience for passengers. Moreover, they are used in railway systems, where they facilitate the smooth movement of trains along tracks.

Benefits of Using Roller Guides

The use of roller guides offers numerous advantages. First and foremost, they reduce friction, which in turn minimizes energy consumption. This efficiency is not only environmentally friendly but also cost-effective, as it leads to less wear on machinery and decreased maintenance costs.

Moreover, roller guides enhance accuracy in motion, which is vital in industries where precision is a requirement. The stability they provide contributes to overall operational reliability, reducing the likelihood of errors and increasing output quality.

Conclusion

In summary, roller guides are essential components in motion control systems across various industries. Their ability to facilitate smooth and precise movements makes them invaluable in applications ranging from manufacturing to transportation. By reducing friction and enhancing accuracy, roller guides play a critical role in improving efficiency and reliability, ultimately contributing to the success of modern technological systems. As industries continue to evolve, the importance of such innovative components will undoubtedly grow.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025